Manufacturing process of large-diameter printing roller for blanket flat screen printing

A printing roller, flat screen printing technology, applied in the field of textile printing and dyeing, can solve the problems of large workshop length and space occupation, large floor area of flat screen screen, long machine length, etc., to achieve compact structure, internal Moderate stress, reducing the effect of occupying plant space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

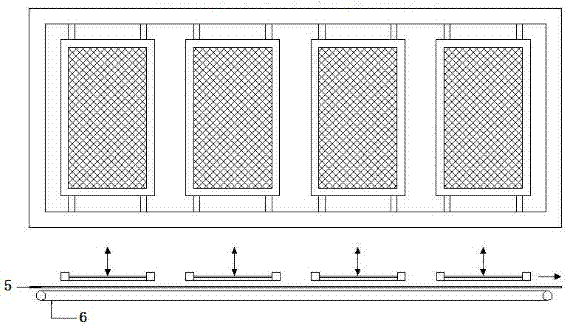

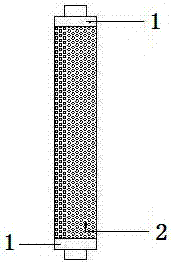

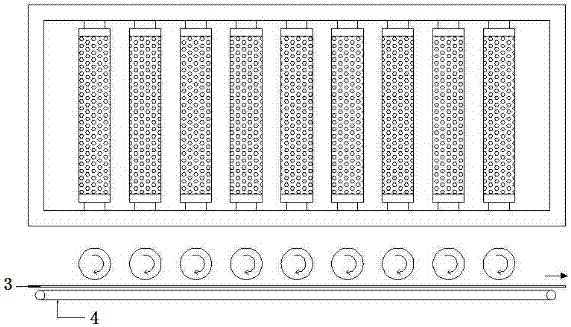

[0052] Such as figure 2 As shown, a large-diameter printing roller that replaces blanket flat screen printing, the large-diameter printing roller 2 is a hollow cylindrical roller; the surface of the roller is evenly distributed with fine meshes according to the requirements of the blanket printing production process hole.

[0053] The manufacturing process of a large-diameter printing roller (taking a roller circumference of 1450mm as an example) that replaces blanket flat screen printing includes the following steps:

[0054] a. Preparation of printing roller mold

[0055] a1. The base mold steel blank is turned, greased, cleaned, and the bottom nickel layer is pre-plated, and then placed in the copper plating tank to electroplate the copper layer to obtain the copper blank mold;

[0056] a2. Carry out the machining and dimensions of the copper blank mold as shown in Table 1, and then clean and polish;

[0057] Table 1.

[0058]

[0059] a3. After the copper blank mold is polished and...

Embodiment 2

[0080] A large-diameter printing roller that replaces flat screen printing on blankets. The large-diameter printing roller 2 is a hollow cylindrical roller; the surface of the roller is evenly distributed with fine meshes according to the requirements of the blanket printing production process.

[0081] The manufacturing process of a large-diameter printing roller (taking a roller circumference of 1450mm as an example) that replaces blanket flat screen printing includes the following steps:

[0082] a. Preparation of printing roller mold

[0083] a1. The base mold steel blank is turned, greased, cleaned, and the bottom nickel layer is pre-plated, and then placed in the copper plating tank to electroplate the copper layer to obtain the copper blank mold;

[0084] a2. Carry out the processing and dimensions of the copper blank mold as shown in Table 4, and then clean and polish;

[0085] Table 4

[0086]

[0087] a3. After the copper blank mold is polished and polished, use an 80M male mol...

Embodiment 3

[0108] A large-diameter printing roller that replaces flat screen printing on blankets. The large-diameter printing roller 2 is a hollow cylindrical roller; the surface of the roller is evenly distributed with fine meshes according to the requirements of the blanket printing production process.

[0109] The manufacturing process of a large-diameter printing roller (taking a roller circumference of 1450mm as an example) that replaces blanket flat screen printing includes the following steps:

[0110] a. Preparation of printing roller mold

[0111] a1. The base mold steel blank is turned, greased, cleaned, and the bottom nickel layer is pre-plated, and then placed in the copper plating tank to electroplate the copper layer to obtain the copper blank mold;

[0112] a2. Carry out the processing and dimensions of the copper blank mold as shown in Table 7, and then clean and polish;

[0113] Table 7

[0114]

[0115] a3. After the copper blank mold is polished and polished, use a 60M male mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com