Wood flour crushing and finish machining device

A wood flour and pulverizer technology, applied in the field of wood flour processing, can solve problems such as large investment cost, and achieve the effect of improving output and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

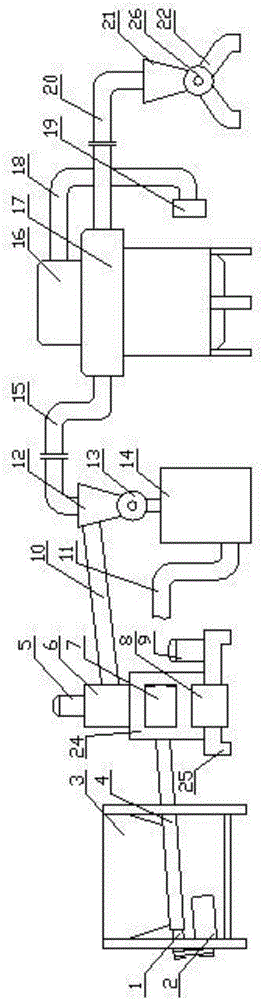

[0018] Such as figure 1 As shown, a wood flour crushing and finishing device includes a feeding device, at least one of which is provided with the feeding device, and the feeding device includes a storage hopper 3, and a feeding pipe 4 is arranged below the storage hopper 3, The discharge end of each of the feed pipes 4 is connected to a pulverizer 24 respectively, and a first sieving device 6 is arranged above the pulverizer 24, and a first conveying device 6 is provided on the first sieving device 6. pipe 10, the first conveying pipe 10 is also connected to the second screening device 12, a first air blower 13 is provided below the second screening device 12, and a storage box 14 is provided below the first air blower 13 , the side below of the storage box 14 is provided with a circulation pipeline 11, and the top of the second screening device 12 is provided with a second delivery pipe 15, and the second delivery pipe 15 is also connected with the sub-sieve recovery tower 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com