Multi-stage vacuum adsorption device and processing method for magnetorheological plane polishing

A technology of vacuum adsorption and magnetorheology, which is applied in the direction of grinding workpiece brackets, etc., can solve the problems affecting the accuracy of the substrate surface of the clamped parts, the uneven surface of the workpiece, and the brokenness of the workpiece, and achieve the effect of convenient and practical clamping mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

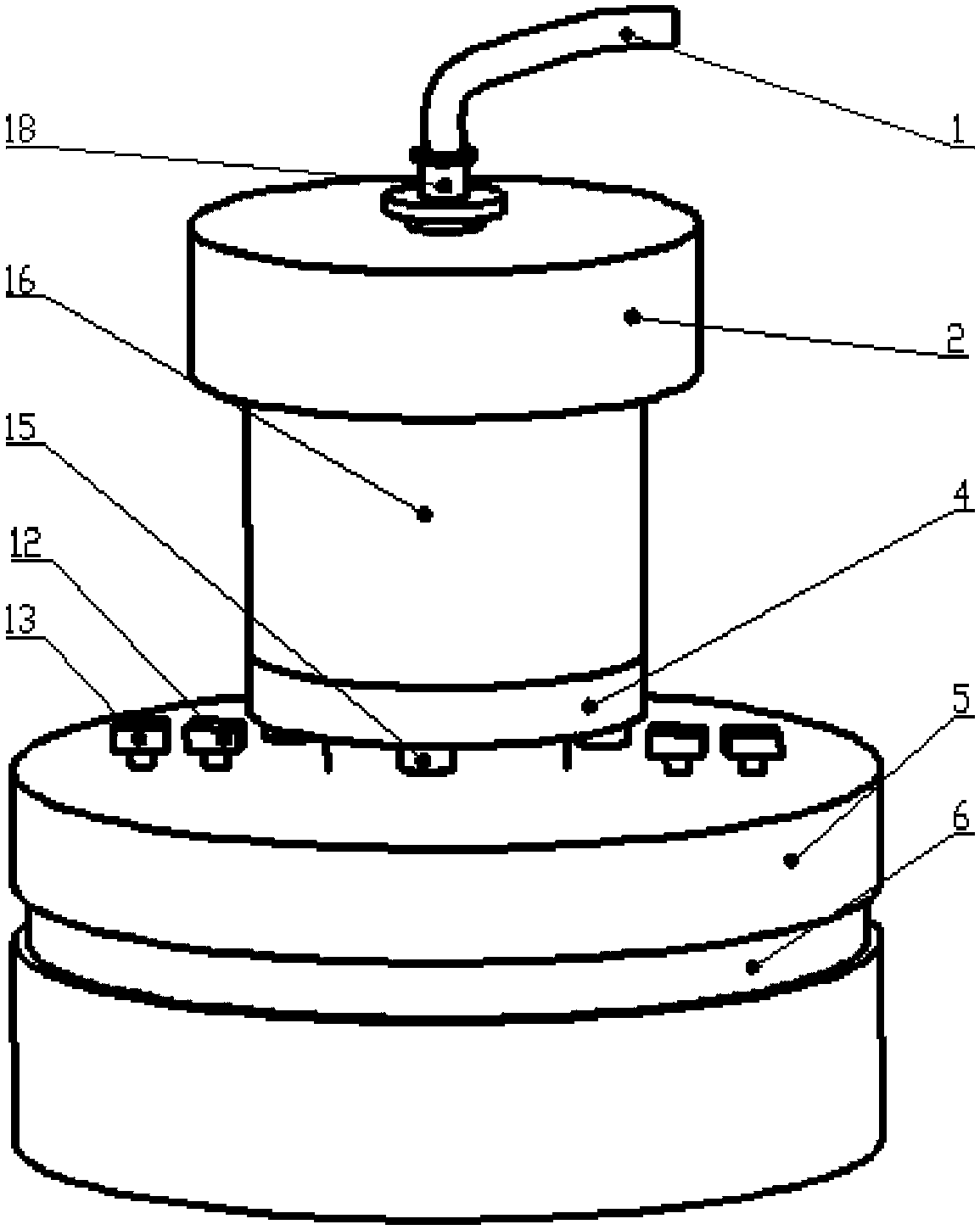

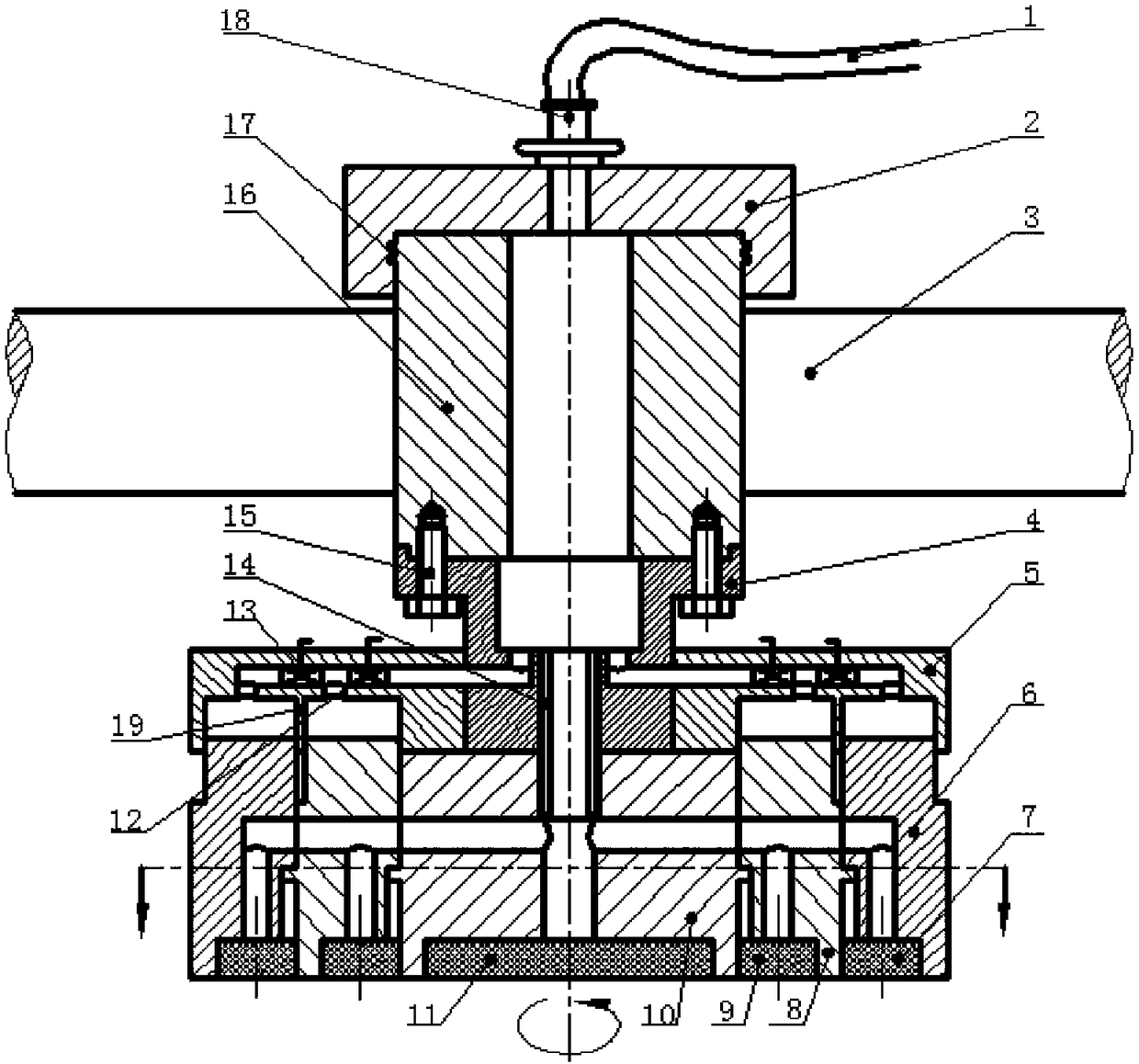

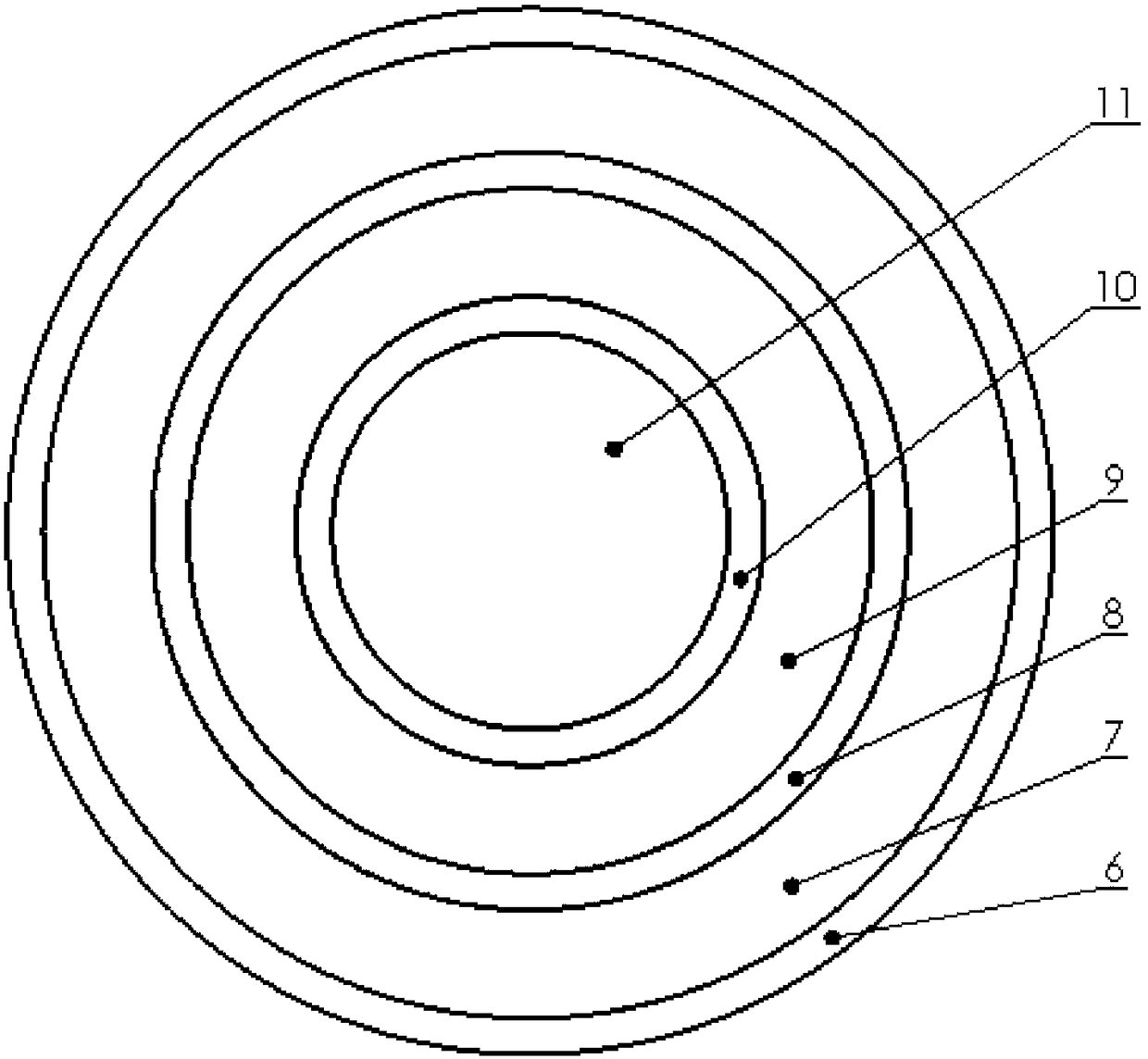

[0030] Such as Figure 1 ~ Figure 3As shown, the multi-stage vacuum adsorption device for magnetorheological plane polishing of the present invention includes a vacuum adsorption generating device, a different stage conversion device, and a vacuum adsorption device. The vacuum adsorption generating device includes an air guide tube 1, a rotary joint 2, and a substrate 3 , the main shaft 16, the air guide joint 18, the conversion device of different stages includes the connection sleeve 4, the end cover 5, the manual ball valve 13, the connecting pipe 14, the vacuum adsorption device includes the three-stage fixing part 6, the three-stage porous ceramic disc 7, The secondary fixing part 8, the secondary porous ceramic disc 9, the primary fixing part 10, and the primary porous ceramic disc 11, wherein the air duct 1 and the rotary joint 2 are fixed together, and the rotary joint 2 is fixed above the main shaft 16, and the main shaft 16 It is fixed by the base body 3, the connect...

Embodiment 2

[0053] The structure of the present invention is the same as that of the first embodiment, except that the workpiece 26 is a three-inch single-crystal sapphire.

[0054] Such as Image 6 As shown, during work, the vacuum adsorption of the primary porous ceramic disc 11 and the secondary porous ceramic disc 9 drives the workpiece 26 to rotate, the workpiece 26 and the flexible micro-grinding head 29 keep in contact, and the tertiary porous ceramic disc 7 moves to the top, Avoid contact with the flexible micro-grinding head 29 to wear the surface.

[0055] In this embodiment, the preparation method of the magnetorheological fluid 27 is: add carbonyl iron powder with a mass percentage of 18% and an average particle diameter of 3.5 microns in the deionized water of the base carrier liquid, with a mass percentage of 6% and an average particle diameter of 5 micron diamond abrasives, 5% glycerin by mass percentage, and 3% by mass antirust agent.

[0056] In this embodiment, the abo...

Embodiment 3

[0062] The present invention is identical with the structure of embodiment one, and difference is that workpiece 26 is the monocrystalline silicon of four inches

[0063] Such as Figure 7 As shown, when working, the workpiece 26 is driven to rotate under the vacuum adsorption of the first-level porous ceramic disc 11, the second-level porous ceramic disc 9 and the third-level porous ceramic disc 7, and the workpiece 26 and the flexible micro-grinding head 29 keep in contact.

[0064] In this embodiment, the preparation method of the magnetorheological fluid 27 is: adding carbonyl iron powder with a mass percentage of 20% and an average particle diameter of 3.5 microns in the deionized water of the base carrier liquid, with a mass percentage of 6% and an average particle diameter of 1 micron aluminum oxide abrasive, 6% by mass of glycerin, and 4% by mass of antirust agent.

[0065] In this embodiment, the above-mentioned magnetorheological planar polishing uses a multi-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com