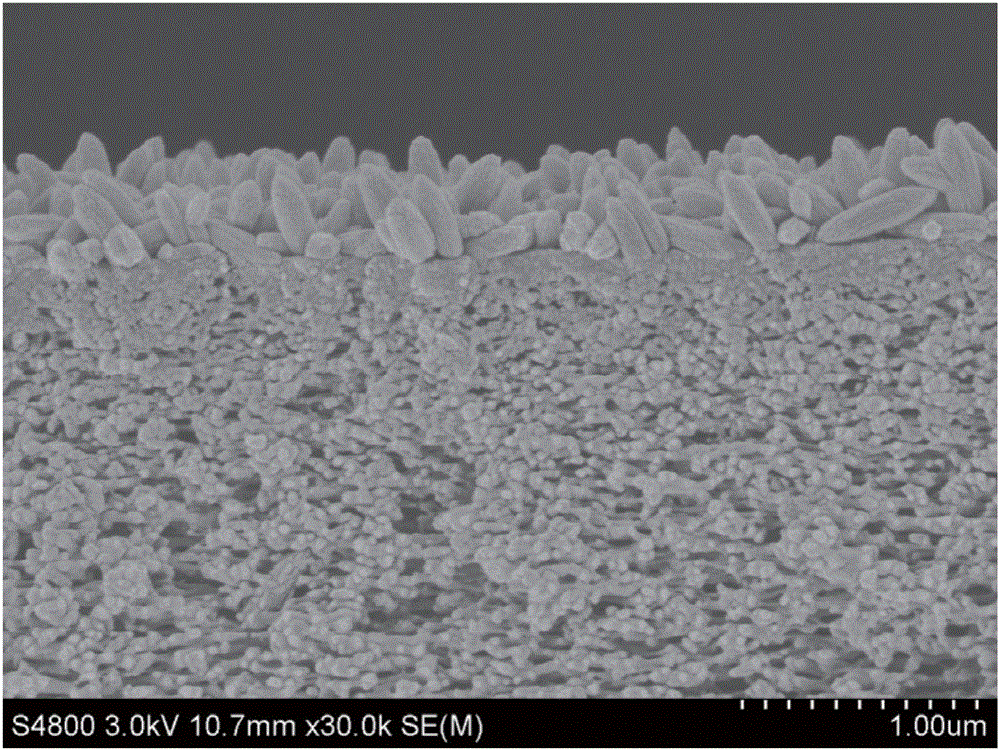

Beta-FeOOH nanocrystal-loaded photocatalytic composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and nanocrystal technology, applied in the field of nanofiltration membranes, can solve problems such as inapplicability of polymer membranes, improve separation efficiency and service life, do not cause secondary pollution, and enhance the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Immerse the polyacrylonitrile ultrafiltration membrane in a sodium hydroxide solution with a concentration of 6wt%, react at 50°C for 1h, then soak and neutralize it with a 1mol / L hydrochloric acid solution overnight, and finally rinse it with deionized water until neutral , to obtain a hydrolyzed polyacrylonitrile ultrafiltration membrane.

[0052] (2) Weigh an appropriate amount of dopamine and polyethylenimine (Mw=600) and dissolve them in Tris buffer, prepare a coprecipitation solution whose concentration is 2 mg / mL, and immerse the hydrolyzed polyacrylonitrile ultrafiltration membrane into In the co-deposition solution, shake and deposit at 25°C for 2 hours, take it out, wash it with ultrapure water for 5 times, and place it in ultrapure water for 12 hours; then immerse the membrane in an ethanol solution with a concentration of 2% glutaraldehyde , reacted in a water bath at 50°C for 20 minutes, took it out and dried it in the air, rinsed it with ultrapure wate...

Embodiment 2~5

[0056] The concentrations of dopamine and polyethyleneimine in the co-deposition solution were adjusted, and other conditions were the same as in Example 1.

Embodiment 6~9

[0064] Regulate the co-deposition time of dopamine and polyethyleneimine, and all the other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com