Treatment system for exhaust emission pollution of ship engine, comprehensive sewage and domestic rubbish

A technology of domestic waste and treatment system, applied in the fields of environmental engineering and ship engineering, can solve the problems of domestic waste pollution, comprehensive sewage, ship engine exhaust pollution, etc., achieving low energy consumption, low operating cost, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

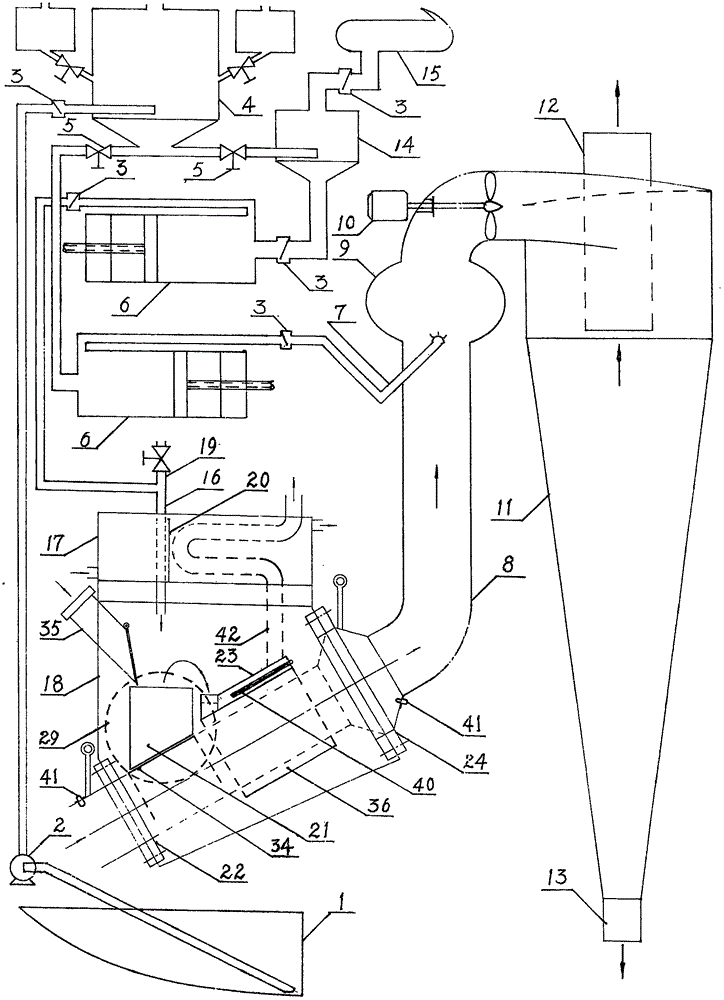

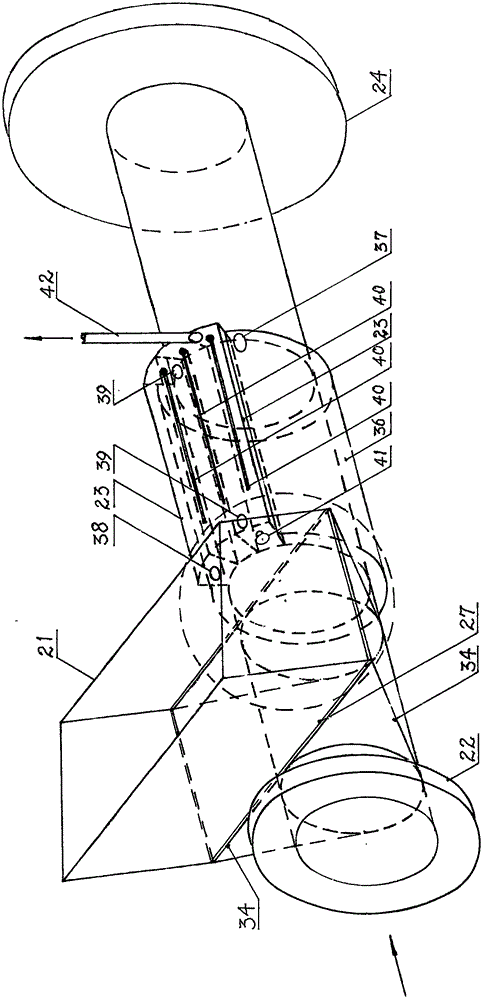

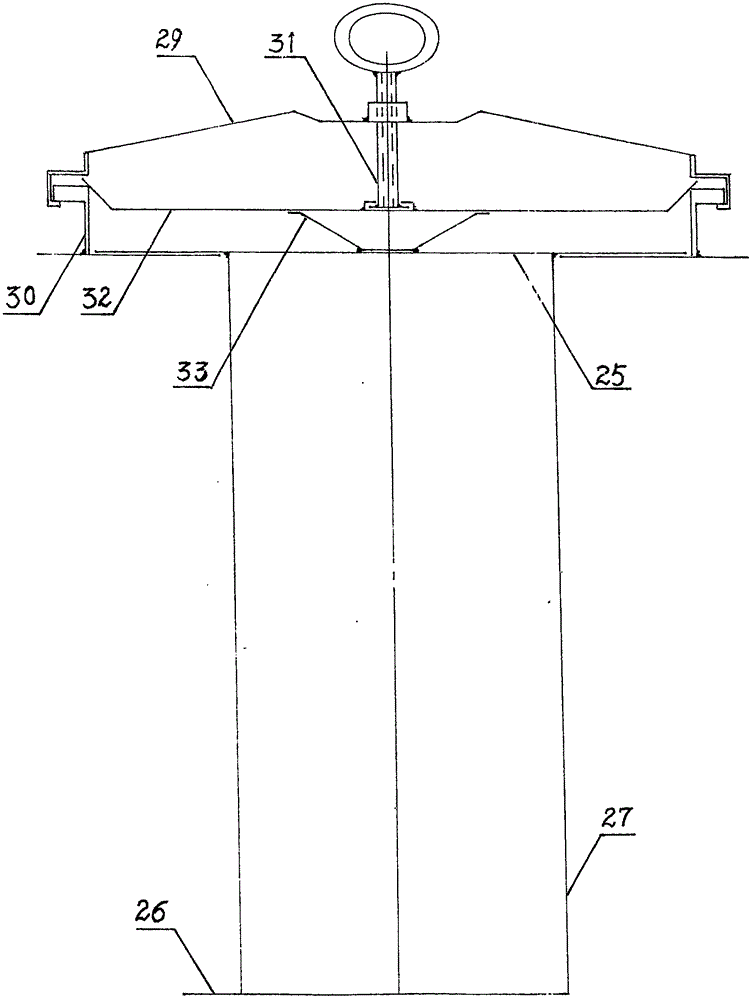

[0025] Sewage tank 1 is tangentially connected to mixed sedimentation tank 4 equipped with dosing tank and electromagnetic valve 5 through water pump 2 and check valve 3. Plunger metering pump 6 with fast action, slow pushing action, piston reciprocating motion, and piston rod rotating motion. 9. The water supply nozzle 7 is placed in the expansion joint 9 or the exhaust gas pipe 8 with a temperature of 360-600 degrees Celsius and a pressure of 2-4Mpa. The fan 10 is installed on the exhaust gas pipe 8 or not, and the end of the exhaust gas pipe 8 is tangentially connected to the circle. On the upper part of the cylindrical dust collector 11, the concentric dust isolation cylinder arranged in the dust collector 11 extends upwards and connects with the dust collector exhaust port 12 provided on the top, and the dust collector ash outlet 13 is arranged at the bottom of the dust collector 11;

[0026] The other end of the lower part of the mixed sedimentation tank 4 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com