A manufacturing method for a foam glass plate

A manufacturing method and foam glass technology are applied in the manufacturing field of foam glass sheets, which can solve the problems of difficulty in controlling the gravity value, difficult control of the weight of carbon particles, and difficult to achieve perfect use, and achieves saving manufacturing cost, simple manufacturing method and shortening The effect of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

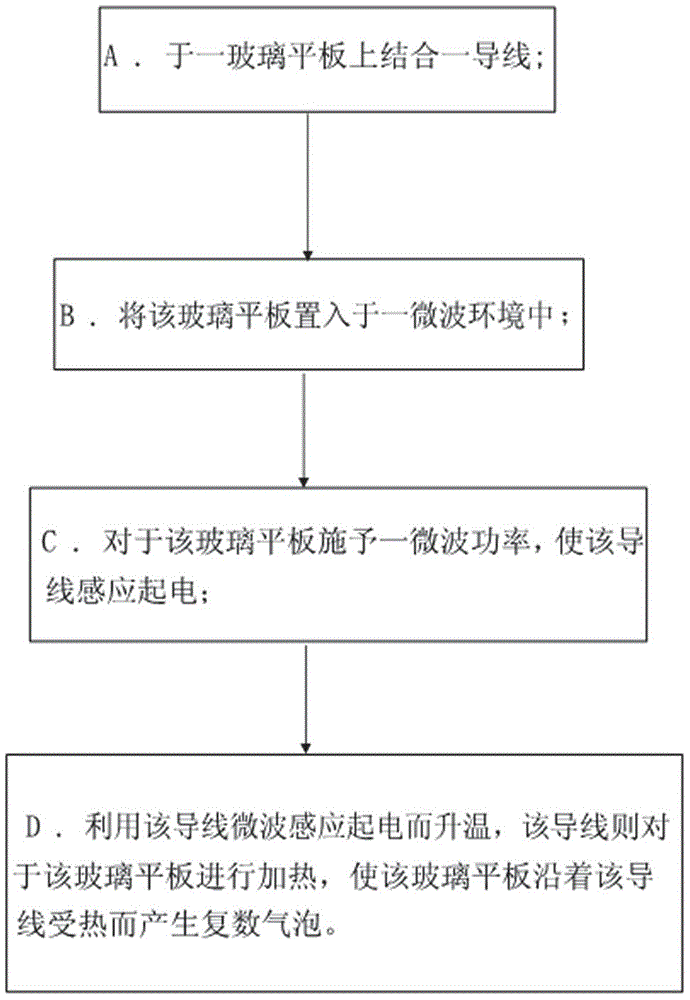

[0045] First, see figure 1 As shown, the embodiment of the present invention includes the following steps:

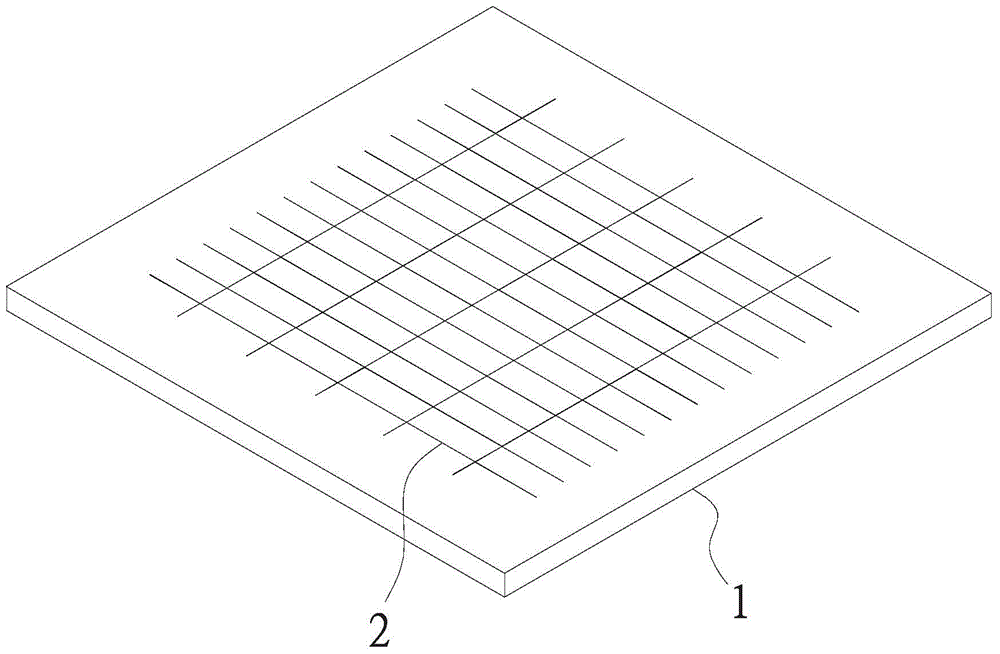

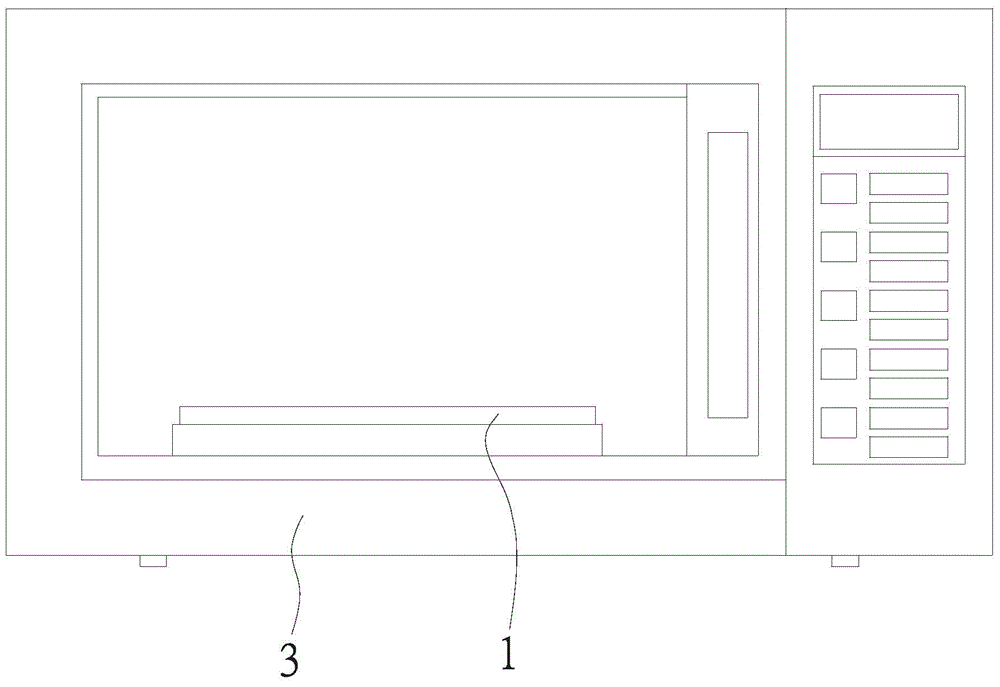

[0046] A. Combine a wire on a glass plate: It can be combined with a wire 2 on the surface of a glass plate 1 by electroplating. The material of the wire 2 is one of copper, aluminum, gold, silver or nickel or In its combination, the width of the wire is 2 to 500 microns, and the wire 2 can also be electroplated on the surface of the glass plate with an indium tin oxide conductive film, and the arrangement of the wire 2 can be longitudinal, horizontal, or crisscross. 〔Such as figure 2 As shown), or according to the different requirements of electromagnetic wave separation, or sound insulation, heat insulation, etc., any arrangement and combination can be made. In order to achieve the purpose of resource recovery and environmental protection, the present invention can also use the glass substrate of the general waste liquid crystal panel. Used as the glass plate 1 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com