Manufacturing process of surf board

A technology for making crafts and surfboards, applied in lamination auxiliary operations, special-purpose vessels, chemical instruments and methods, etc., can solve problems such as life-threatening, surfing failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

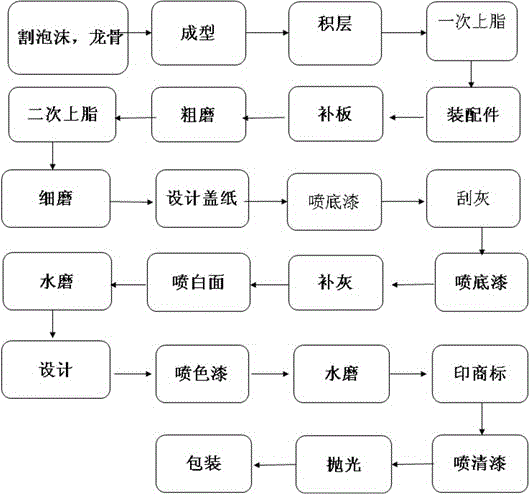

[0050] The steps of the present invention are as figure 1 shown, including:

[0051](1) Material preparation: select foam boards with standard density, cut them out according to the shape requirements of the foam boards, add keels to those designed with keels, and add keels to the middle of the foam boards. The keel used by the inventor is an integral solid wood keel. The most reasonable density distribution can be achieved through the combination of solid wood keel and foam board, so that athletes have a better control experience. At the same time, because the solid wood keel supports the overall foam board, the surfboard The stability is higher.

[0052] (2) Forming: According to the requirements of customers, make the shape of the board.

[0053] (3) Lamination: Lay glass fiber cloth on the formed foam board. The foam board is divided into two sides, the face and the bottom. Among them, the face is covered with 3 layers of glass fiber cloth, and the bottom is covered with...

Embodiment 2

[0075] Same as Example 1, the difference is: the coarse grinding roughness of the step (5) is Ra<2um.

[0076] Only when the roughness of rough grinding is less than 2 um can it be helpful for the implementation of the subsequent steps and achieve the technical effect required by the latter steps, because if the roughness is greater than 2 um, the subsequent grinding time will increase, resulting in epoxy resin and glass fiber cloth The joints of the joints are excessively consumed due to long-term grinding, which affects the service life.

Embodiment 3

[0078] Same as Example 1, the difference is that the roughness of the steps of fine grinding, primary grinding, secondary grinding and water grinding is 1.35 um

[0079] In the above steps, only by impressing this indicator can the athletes achieve the best control experience when using the surfboard, because if the roughness is too high, it will wear the soles of the feet, and if it is too low, it will cause the board to fall off, so the manufacturer needs to control it during the production process. The roughness value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com