Quantitative analysis method for surface oxygenic functional groups of graphene materials

A surface oxygen-containing, quantitative analysis technology, which is applied in the direction of chemical analysis by titration, can solve the problems of inability to carry out quantitative analysis, affect application performance, and single conditions, and achieve low test cost, accurate and reliable results, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

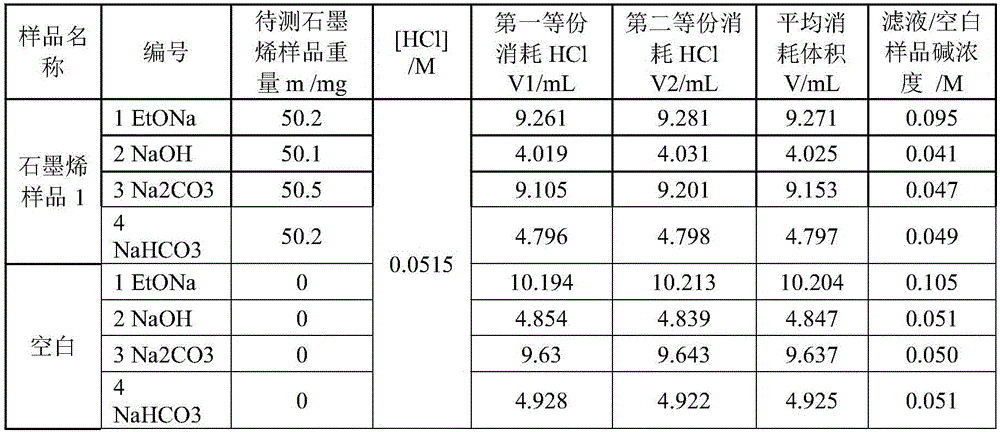

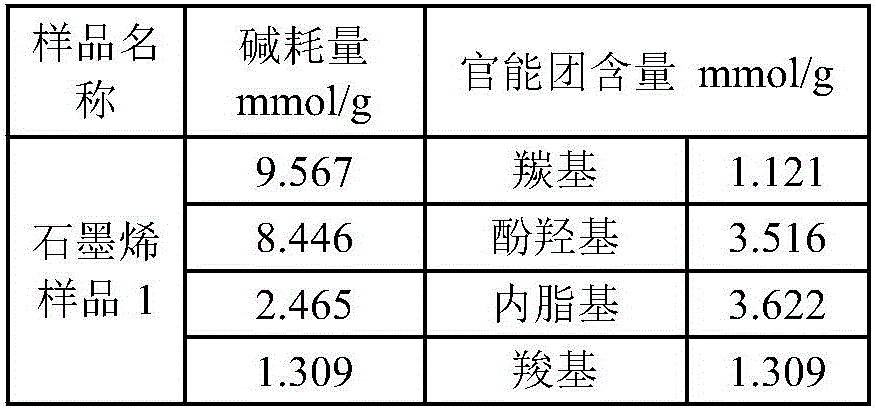

Embodiment 1

[0066] (1) According to the instructions in GBT 601-2002, prepare 0.05M NaOH and NaHCO with deionized water with a resistivity of 10MΩ 3 、Na 2 CO 3 and HCl aqueous solution, and prepare 0.1M EtONa solution with absolute ethanol. Weigh the working standard reagent potassium hydrogen phthalate, which was dried to constant weight in an electric oven at 105°C, dissolve it in carbon dioxide-free water, and titrate it with the prepared NaOH solution on the potentiometric titrator, and obtain the titration according to the entire titration curve. At the end point, the concentration of NaOH was calculated. Use the calibrated NaOH standard solution to calibrate the concentration of the HCl solution. Use the calibrated HCl standard solution to titrate NaHCO directly on the potentiometric titrator 3 、Na 2 CO 3 Aqueous solution and EtONa ethanol solution;

[0067] (2) Dry the graphene sample 1 to be tested in a vacuum drying oven at 80°C for 12 hours, then cool it to room temperatu...

Embodiment 2

[0080] (1) According to the instructions in GBT 601-2002, prepare 0.05M NaOH and NaHCO with deionized water with a resistivity of 15MΩ 3 、Na 2 CO 3 and HCl aqueous solution, and prepare 0.1M EtONa solution with absolute ethanol. Weigh the working standard reagent potassium hydrogen phthalate, which was dried to constant weight in an electric oven at 107°C, dissolve it in carbon dioxide-free water, add 2 drops of phenolphthalein indicator, and titrate with the prepared NaOH solution, the color of the solution turns pink When the color remains unchanged for 30s, it is the end point of the titration, and the concentration of NaOH is calculated. Use the calibrated NaOH standard to calibrate and titrate the concentration of the HCl solution. Direct titration of NaHCO with calibrated HCl standard solution 3 、Na 2 CO 3 aqueous solution and EtONa ethanolic solution, titrate NaHCO 3 、Na 2 CO 3 Add 10 drops of bromocresol green-methyl red indicator solution every now and then, ...

Embodiment 3

[0094] (1) According to the instructions in GBT 601-2002, prepare 0.08M NaOH and NaHCO with deionized water with a resistivity of 15MΩ 3 、Na 2 CO 3 and HCl aqueous solution, and prepare 0.1M EtONa solution with absolute ethanol. Weigh the working standard reagent potassium hydrogen phthalate, which was dried to constant weight in an electric oven at 103°C, dissolve it in carbon dioxide-free water, add 2 drops of phenolphthalein indicator, and titrate with the prepared NaOH solution, the color of the solution turns pink When the color remains unchanged for 30s, it is the end point of the titration, and the concentration of NaOH is calculated. Use the calibrated NaOH standard solution to calibrate the HCl solution concentration, and use the calibrated HCl standard solution and NaOH standard solution to back-titrate NaHCO 3 、Na 2 CO 3 aqueous solution and EtONa ethanol solution.

[0095] (2) Dry the graphene sample 1 to be tested in a vacuum drying oven at 100°C for 8 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com