A surface plasmon resonance sensor chip and its preparation method and application

A surface plasmon and sensor chip technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of expensive CM5 chips, high instrument maintenance costs, lack of flexibility, etc., achieve high fixed capacity, short cycle, good Effect of SPR Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

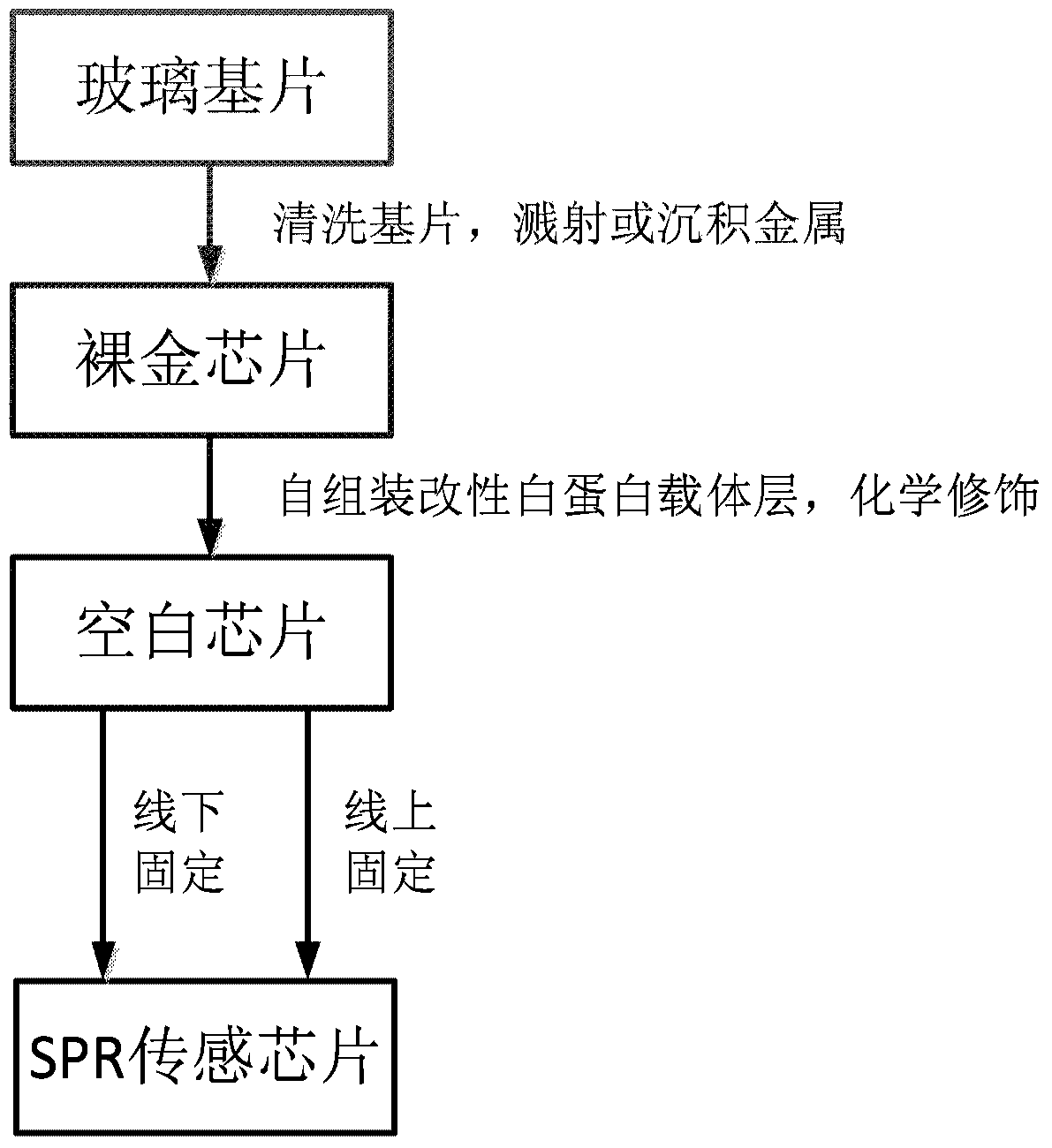

[0064] Such as figure 1 As shown, it is a schematic flow diagram of the preparation method of the present invention. Specifically, the preparation method of the surface plasmon resonance sensor chip of the present invention comprises the following steps:

[0065] (1) Cleaning the glass substrate: washing the glass substrate with concentrated sulfuric acid and deionized water successively, and drying;

[0066] (2) A chromium film with a thickness of 3-10nm is prepared on a glass substrate by sputtering or deposition, and then a gold film with a thickness of 45-55nm is prepared on the chromium film. The solid-phase carrier of the sensor chip is made into a bare gold chip;

[0067] (3) Drop the solution containing modified bovine serum albumin on the bare gold chip, so that the solution evenly covers the entire chip, continue to drop until the entire chip is soaked, seal the oscillation reaction, and use the self-assembly method to carry out the surface of the gold film. Chemi...

preparation Embodiment 2

[0072] The preparation method of the off-line immobilized small molecule detection SPR sensor chip also includes the following step (6), taking the cortisol chip as an example.

[0073] Described step (6) comprises following substep:

[0074] a) Add the mixed solution of NHS and EDC (1:1 mixing, the concentration of NHS 0.1mol / L, the concentration of EDC 0.4mol / L) on the blank chip, so that the solution evenly covers the entire chip, continue to drop until soaked The whole chip is sealed and oscillating, so that the modified bovine serum albumin immobilized on the surface of the gold film undergoes a chemical cross-linking reaction, and reacts at room temperature for 15 minutes to 1 hour, and then cleans and dries the chip;

[0075] b) Drop a cortisol conjugate solution with 0.1M acetic acid buffer as a solvent on the chip, the concentration of the conjugate is 300mg / L, so that the solution evenly covers the entire chip, continue to drop until the entire chip is soaked, seal a...

preparation Embodiment 3

[0078] The preparation method of the online immobilized small molecule detection SPR sensor chip also includes the following step (6), taking the cortisol chip as an example.

[0079] Described step (6') comprises following sub-steps:

[0080] a') Install the blank chip on the surface plasmon resonance biochemical analyzer, and fix the supporting flow cell;

[0081] b') flow into the mixed solution of NHS and EDC (1 to 1 mixing, the concentration of NHS 0.1mol / L, the concentration of EDC 0.4mol / L), so that the modified bovine serum albumin immobilized on the surface of the gold film undergoes chemical For cross-linking reaction, react at room temperature for 7 minutes to 0.5 hours, and then wash with PBS buffer;

[0082] c') flow into the cortisol conjugate solution with 0.1M acetate buffer as solvent, the concentration of the conjugate is 100mg / L, react at room temperature for 10 minutes to 1 hour, and then flow wash with PBS buffer;

[0083] d') Continuously and slowly flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com