Method for determining plane stress fracture toughness and yield strength of aluminum alloy material by structure yield load

An aluminum alloy material and fracture toughness technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem that the fracture toughness test method is not given, the production cost of test specimens and the test workload are increased and aggravated. The difficulty of test operation and other problems have achieved the effect of loose test conditions, easy operation and implementation, and easy promotion and implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

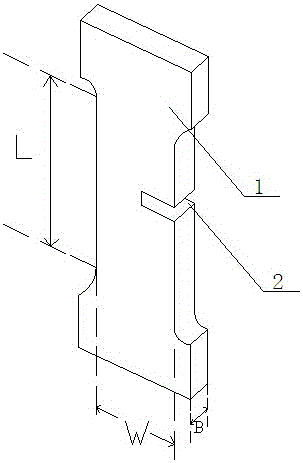

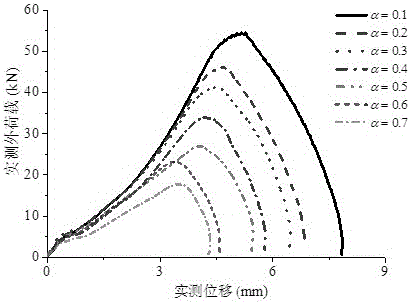

[0047] Example 1: 6061 aluminum alloy materials are used to process and manufacture seven groups of test pieces. The size of the test piece is: W=40mm, B=6.1mm, L=60mm, the height of the arc section of the test piece is 20mm, and the size of the rectangular clamping end is: 70mm×80mm. The wire cutting process was used to cut the initial cracks for each test piece respectively. The width of the initial cracks was less than 0.20mm.

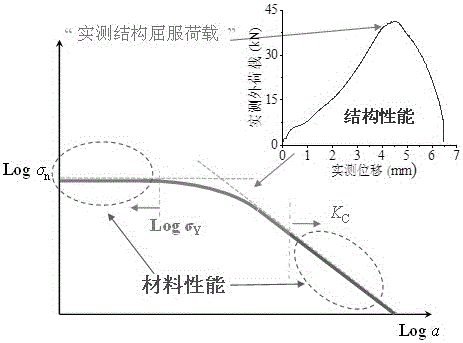

[0048] On the tensile testing machine, load at a constant speed until the specimen breaks according to the rate specified in the "Metallic Materials Tensile Test Part 1: Room Temperature Test Method" (GB / T 228.1-2010) specification. Record the external load-displacement full curve of each cracked specimen during the test, see figure 2 . The material properties (fracture toughness and yield strength) of the aluminum alloy material are determined by the structural properties of the specimen (measured yield load), that is, the structural yield load ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com