Heterodyne spectrometer grating gluing assembling structure and assembling method

A spectrometer and grating technology, which is applied in the adjustment structure and field of heterodyne spectrometer grating bonding, can solve the problems of long curing time, degradation of interference signal quality, poor recovery performance of adjustment mechanism, etc., and achieve the effect of gluing and curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

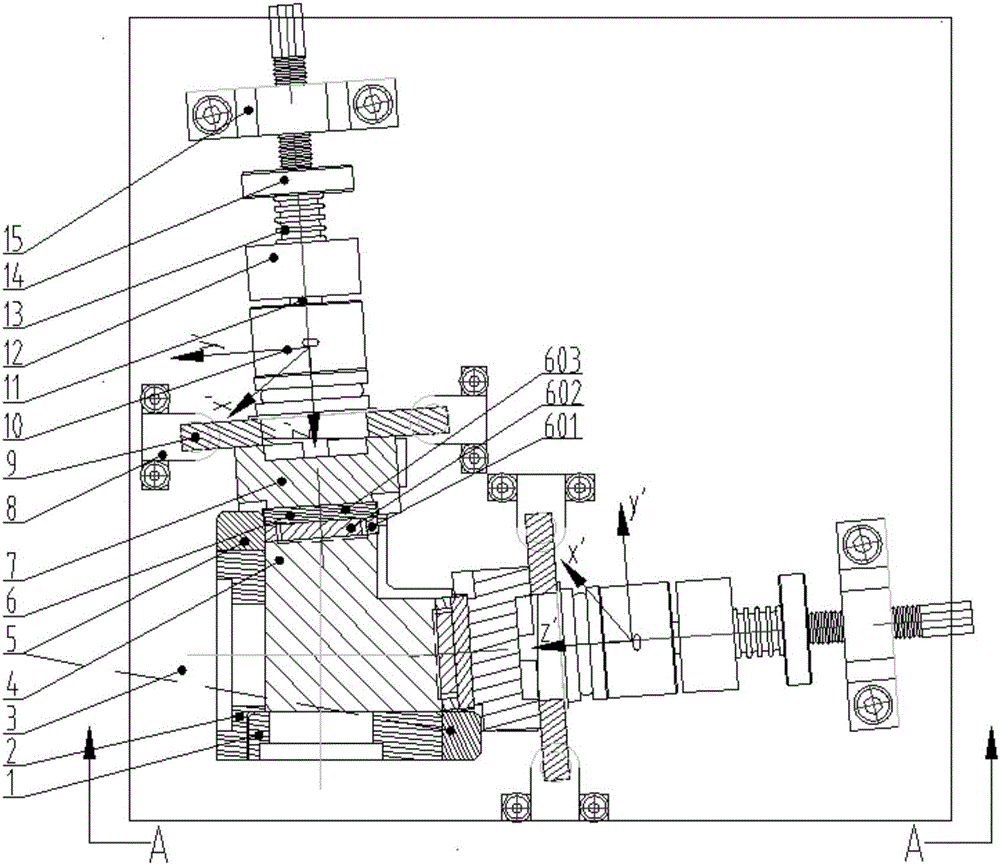

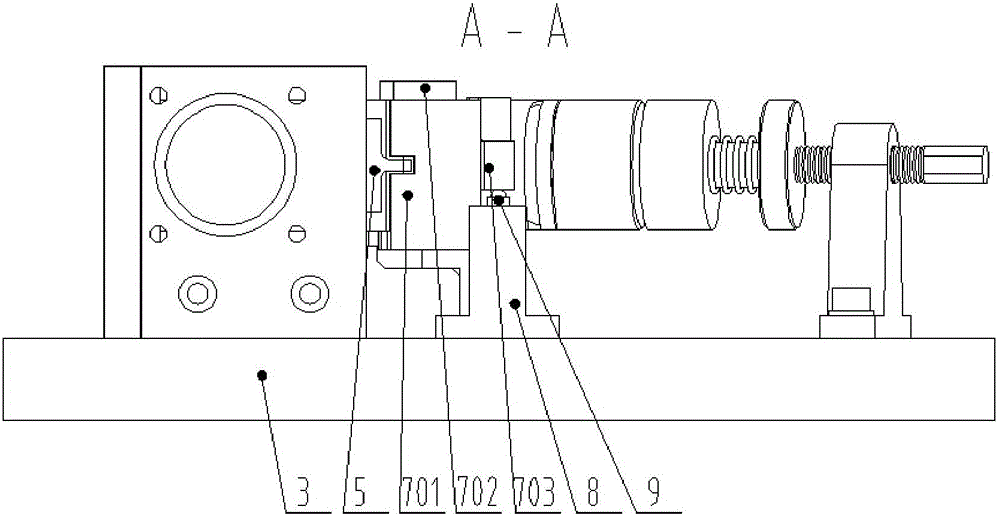

[0028] Such as figure 1 , 2 As shown, on the support base plate 3, the three vertical plane references composed of the collimation adapter plate 1, the imaging adapter plate 2 and the support base plate 3 are installed, and the "L"-shaped interference assembly 4 to be glued is placed closely on the On the basis of three vertical planes, grating components 6 are installed on the two arms of the "L" shape of the interference component 4 to be glued, and the grating components 6 are installed in the grating seat component 7; Adjustment structure, positioning and adjustment structure is composed of two-dimensional positioning mechanism and rotation adjustment mechanism;

[0029] The grating box 701 is provided with a bearing pressing sleeve groove on the x'oy' parallel plane, and uniformly distributed openings are provided in the gluing area of the grating assembly 6 and the interference assembly 4 to be glued, so as to realize interference between the outer surface of the grat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com