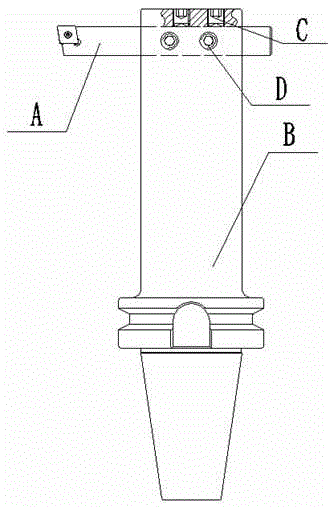

An adjustable single-edged boring tool

A boring tool and order-adjusting technology, which is applied to the attachments of tool holders, tools for lathes, turning equipment, etc., can solve the problems of cumbersome operation process, lack of precise adjustment device for boring tools, complicated structure of pressing method, etc. Easy operation, simple design, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

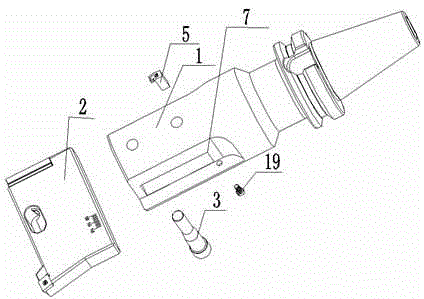

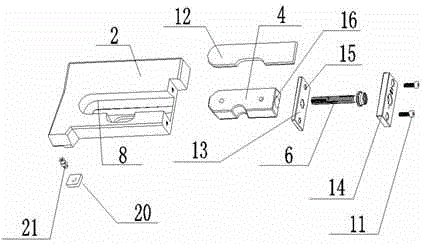

[0025] In order to make the purpose, technical solution and advantages of the invention clearer, the invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0026] The embodiment of the present invention provides an adjustable single-edge boring tool, the structure includes: tool handle (1), boring plate (2), pin (3), slider (4), vernier (5) and fine-tuning drive nut (6), characterized in that the handle (1) is provided with a rectangular hole (7) matching the boring plate (2), and the boring plate (2) is installed in the rectangular hole ( 7), the boring plate (2) is provided with a goose tail groove (8), the slider (4) is precisely inserted into the goose tail groove (8), and the pin (3) is provided with a conical surface ( 9), the slider (4) is provided with a conical hole (10) matching the pin conical surface (9), the fine-tuning drive nut (6) is connected to the boring plate (2) through two screws (11) fixed.

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com