A vertical interferometer standard mirror clamping device and method for surface shape detection of optical components

A clamping device and surface shape detection technology, which is applied in the direction of using optical devices, optical components, measuring devices, etc., can solve the problems of inability to precisely adjust the levelness of standard mirrors, and achieve the effect of simple device structure and guaranteed level accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

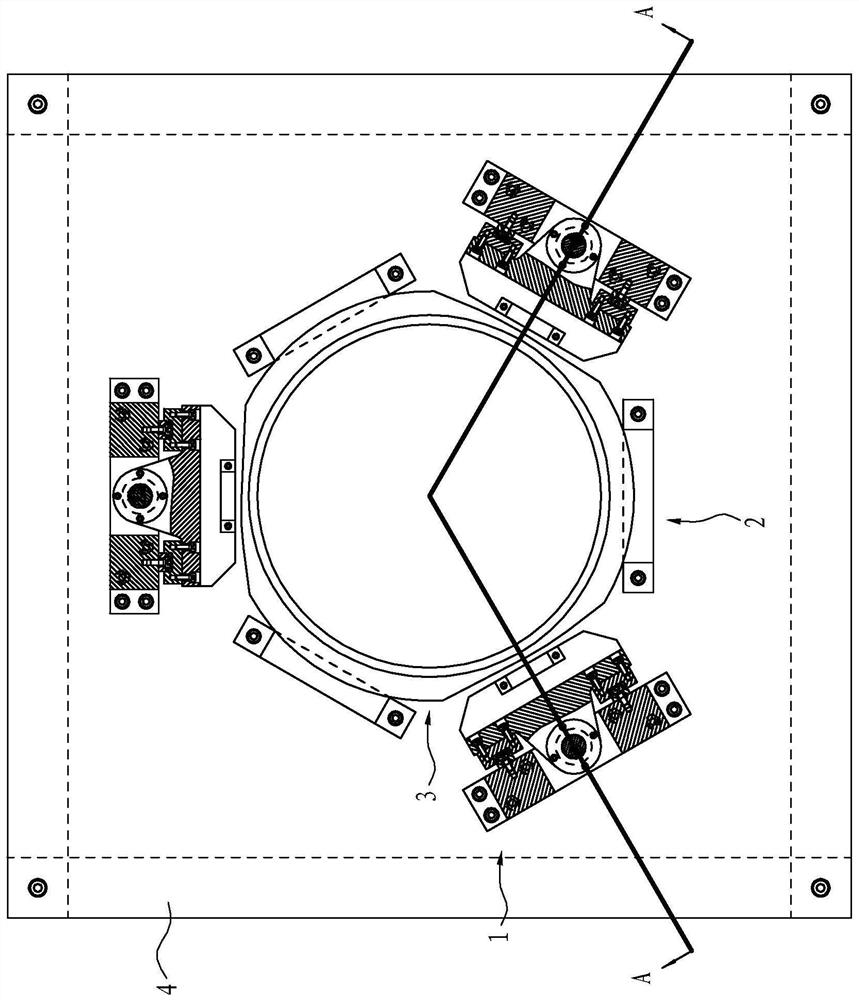

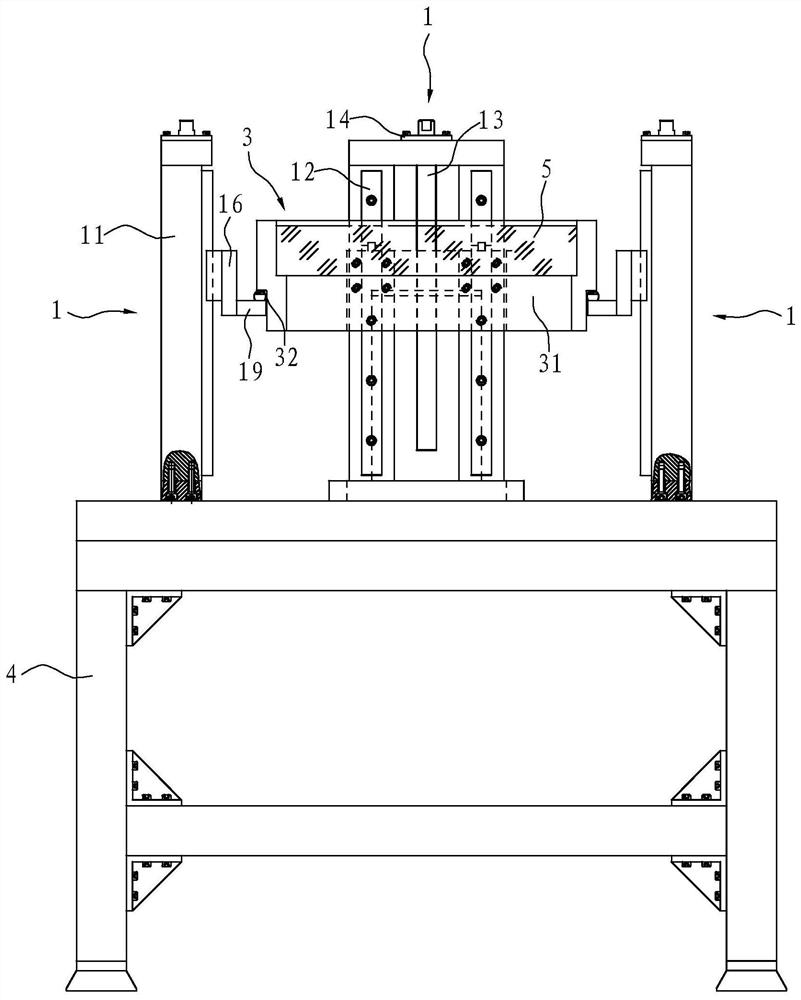

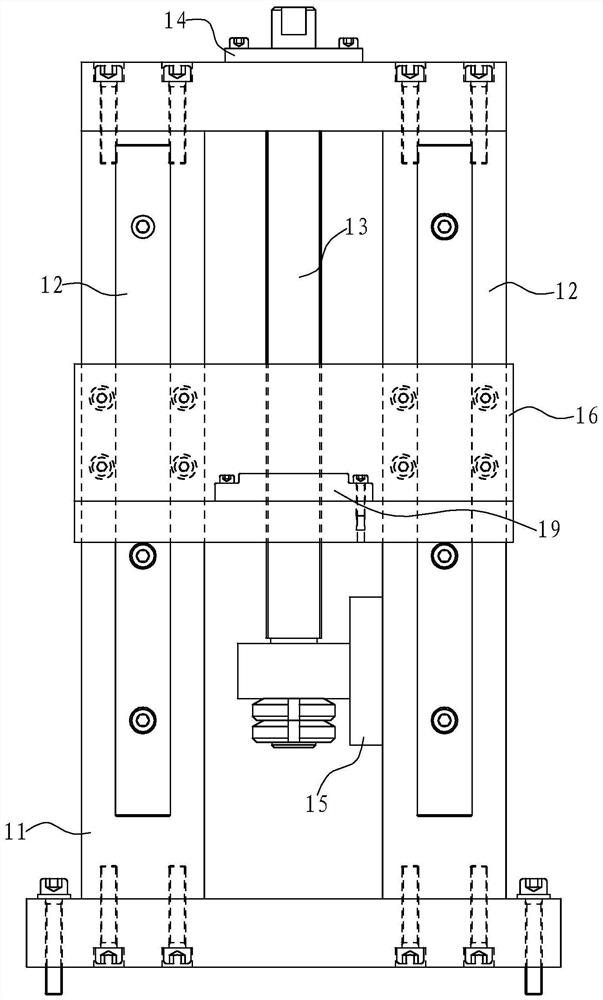

[0033] Such as Figure 1 to Figure 7 As shown, a vertical interferometer standard mirror clamping device for surface shape detection of optical components includes a leveling mechanism 1 , an auxiliary support 2 , a tray 3 and a base 4 . The leveling mechanism 1 and the auxiliary support 2 are installed on the base 4, and the tray 3 is used to place the standard mirror 5.

[0034] The leveling mechanism 1 includes a drive system and a support block 19 for supporting the pallet 3. The drive system can drive the support block 19 to move along the height direction, and the lowest value of the height that the support block 19 can reach is denoted as H min , the highest value is recorded as H max , the auxiliary support 2 includes a bracket 21 and a buffer pad 22 installed on the bracket 21, the buffer pad 22 is used to support the tray 3, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com