Three-freedom-degree precise regulating device based on ball location

A precision adjustment and ball positioning technology, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, etc., can solve the problems of large space occupied by the motion pair, crawling phenomenon of the mechanism, gaps in the motion pair, etc., and achieve excellent dynamic performance , low cost, and the effect of meeting strict restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

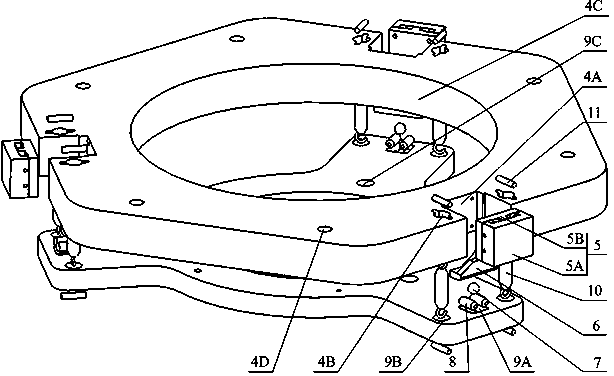

[0024] The specific implementation process of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

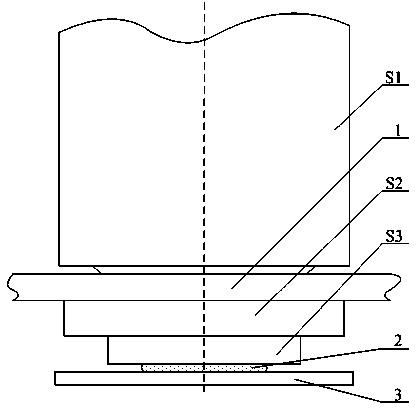

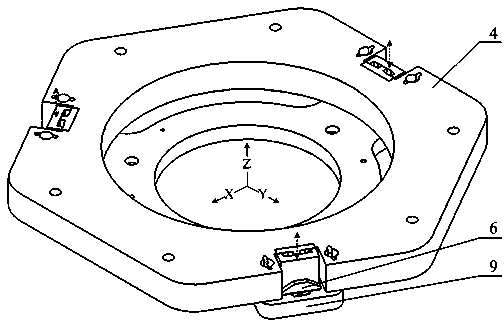

[0025] Such as figure 1 As shown, the optical system S1 of the immersion lithography machine runs through the main frame 1 of the immersion lithography machine, the three-degree-of-freedom precision adjustment device S2 based on ball positioning, and the immersion unit S3 of the immersion lithography machine, and is at the bottom through the immersion flow field 2 The silicon wafer 3 is exposed; the three-degree-of-freedom precision adjustment device S2 based on ball positioning is installed between the main frame 1 of the immersion lithography machine and the immersion unit S3 of the lithography machine, and the three-degree-of-freedom precision adjustment device S2 based on ball positioning passes The installation substrate installation hole 4D is installed on the main frame 1, and the photolithography machine immersion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com