Calibration method for measuring probe for online measurement in processing machine tool

A technology for measuring probes and processing machine tools, applied in the field of mechanical processing, can solve the problems of many conditions, high cost, restricting the precision and quality of processing and manufacturing, and achieve the effects of low cost, space saving, simple design structure and installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

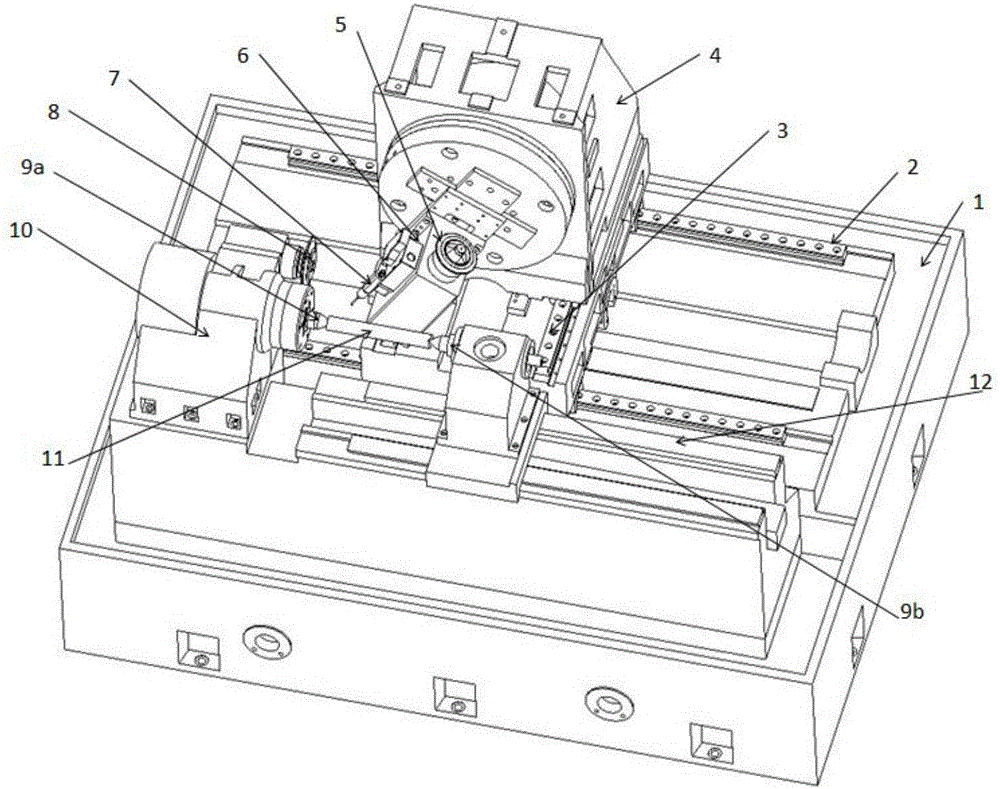

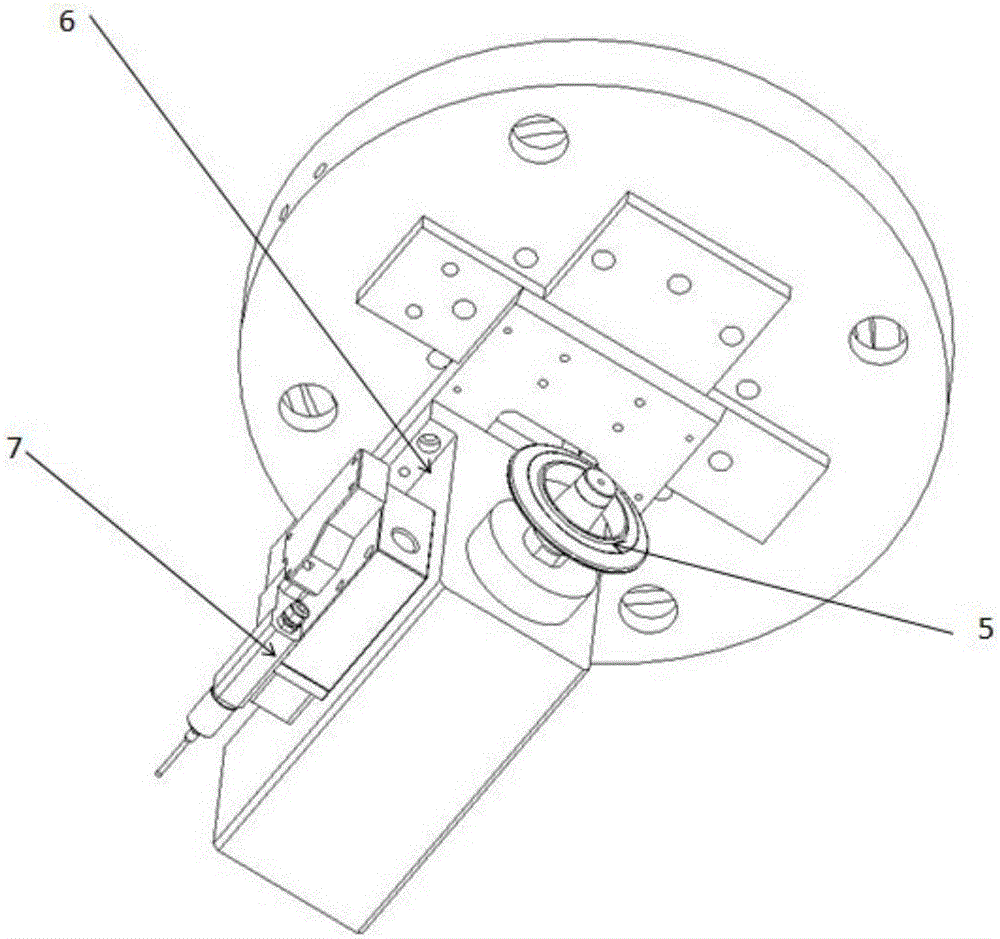

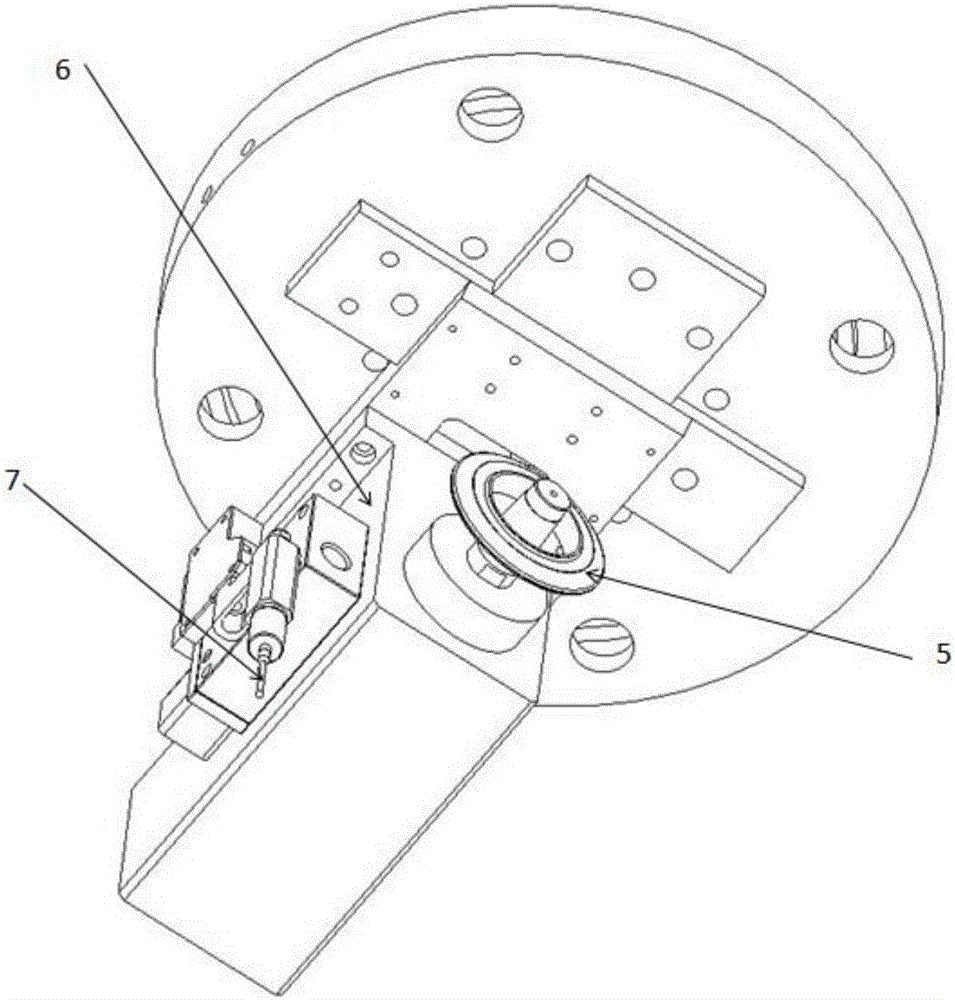

[0026] figure 1 It is an overall schematic diagram of the calibration of the gear grinding machine tool during the calibration work of the calibration method of the measuring probe for on-line measurement in the processing machine tool of the present invention.

[0027] Such as figure 1 As shown, the gear grinding machine tool includes a base 1, a guide rail 2, a guide rail 3, a column 4, a grinding wheel 5, a grinding wheel spindle motor 6, a measuring probe 7, a diamond wheel 8, thimbles 9a and 9b, a workpiece spindle motor 10, a standard measuring rod 11, Guide rail 12 and the control part not shown in the figure.

[0028] Among them, due to the existence of the rotating shaft in the guide rail 2, the guide rail 3 and the column 4, the machine tool spindle has three degrees of freedom, which are the Y axis moving back and forth, the X axis moving left and right, and the B axis of rotation, and the workpiece fixing device is a For the thimbles 9a and 9b, the right thimble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com