Civil explosive article destroying device and method

A technology for destroying devices and objects, applied in blasting and other directions, can solve the problems of fragmentation, unconcentrated drug residues, poor tunnel protection capability, high noise and vibration, etc., to reduce the number and frequency of excavations, reduce the risk, and weaken the explosion. effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

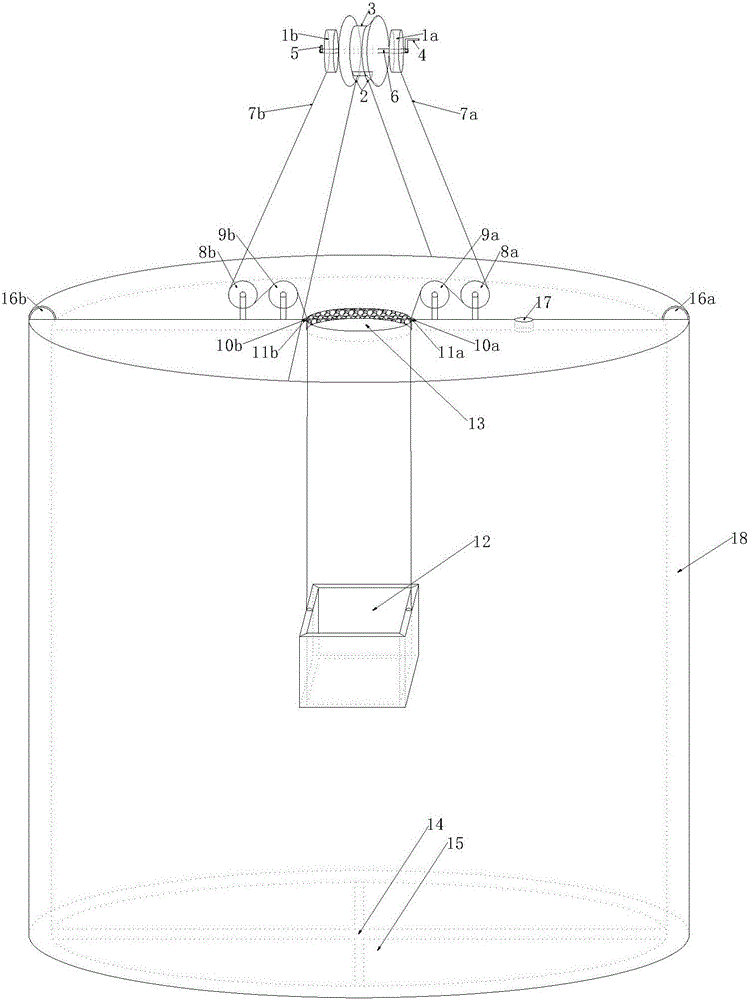

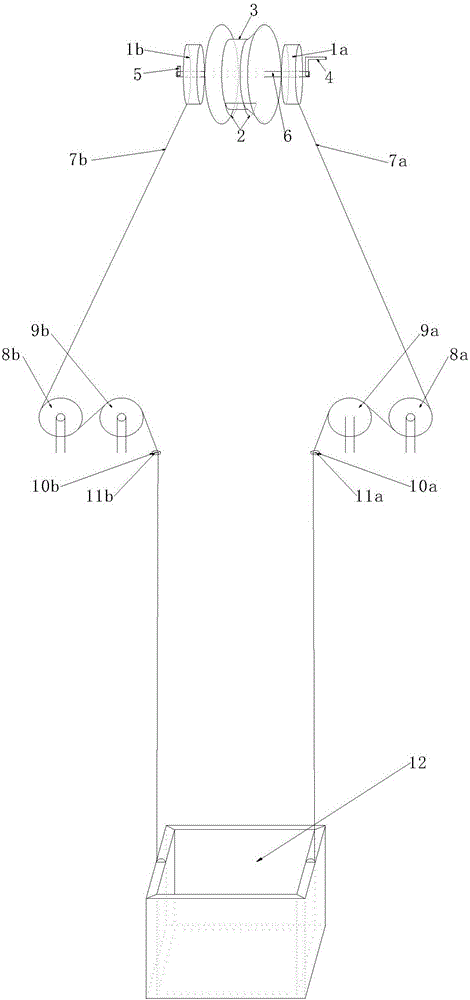

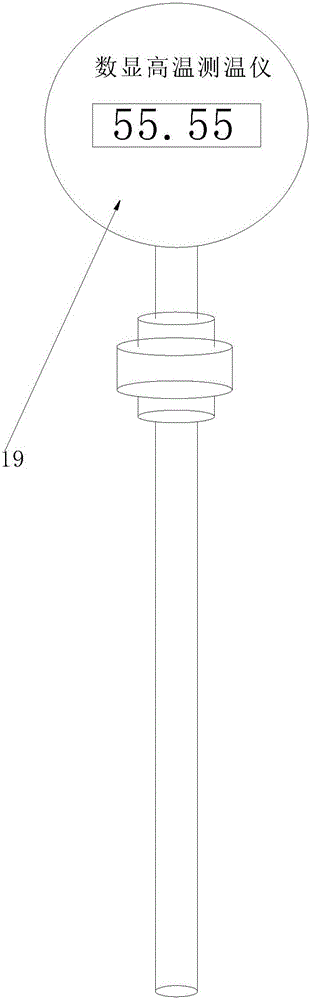

[0029] refer to Figure 1-5 , a civil explosive destruction device, comprising a line control device 3, an explosive steel drum 18, and a monitoring port 17, the lower end of the line control device 3 in the destruction device is fixed on the upper edge of the explosive steel drum 18 through a support rod 2, and the upper edge of the steel drum 18 is The upper explosion vent hole is set in the center of the bottom, and the first wire reel 1a and the second wire reel 1b are respectively arranged on both sides of the wire control device 3, and the first wire reel 1a, the second wire reel 1b and the connecting rod 6 are connected together through bearings, The rod 4 and the bolt are riveted on both ends of the connecting rod 6, and the first wire reel 1a and the second wire reel 1b respectively lead out the first thin wire 7a and the second thin wire 7b respectively connect to the first upper pulley 8a and the second upper pulley 8b in turn, The first lower pulley 9a, the second ...

Embodiment 2

[0038] The structural assembly of the civilian explosives destruction device is the same as that of Embodiment 1, and the different process parameters are: 1. The first lower pulley, the second lower pulley, the first upper pulley, and the second upper pulley are respectively welded to the side of the upper explosion vent hole At 4cm and 12cm, the first and second lifting rings are respectively welded on both sides of the steel drum. A monitoring port with a diameter of 0.08m is opened at the top of the steel drum at a distance of 0.8m from the wall of the steel drum. On the inner wall of the bottom of the steel drum, and the two ends of the steel bar are fixed on the inner wall of the steel drum with bolts, and the entire steel drum is buried in a sandy soil medium with a depth of 0.8m.

[0039] 2. The explosive steel barrel is welded into a circular steel barrel with a diameter of 1.0m by using 10mm thick high-strength steel plate.

Embodiment 3

[0041] The structural assembly of the civilian explosives destruction device is the same as that of Embodiment 1, and the different process parameters are: 1. The first lower pulley, the second lower pulley, the first upper pulley, and the second upper pulley are respectively welded to the side of the upper explosion vent hole At 7cm and 15cm, the first and second lifting rings are respectively welded on both sides of the steel drum. A monitoring port with a diameter of 0.12m is opened at the top of the steel drum at a distance of 1.2m from the wall of the steel drum. On the inner wall of the bottom of the steel drum, and the two ends of the steel bar are fixed on the inner wall of the steel drum with bolts, and the entire steel drum is buried in a sandy medium with a depth of 1.4m.

[0042] 2. The explosive steel barrel is welded into a circular steel barrel with a diameter of 2.0m by using 30mm thick high-strength steel plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com