Heat exchanger for waste heat recovery of coal-fired boiler

A technology for waste heat recovery and coal-fired boilers, applied in feed water heaters, preheating, lighting and heating equipment, etc., can solve the difficulty of recycling and the increase of renovation and maintenance costs, limit the promotion and use of low-temperature heat exchangers, low-temperature dew point corrosion, etc. problems, to achieve the effects of flexible adjustment of exhaust gas temperature, improvement of low-temperature acid dew point corrosion, and prevention of low-temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments and in conjunction with the accompanying drawings.

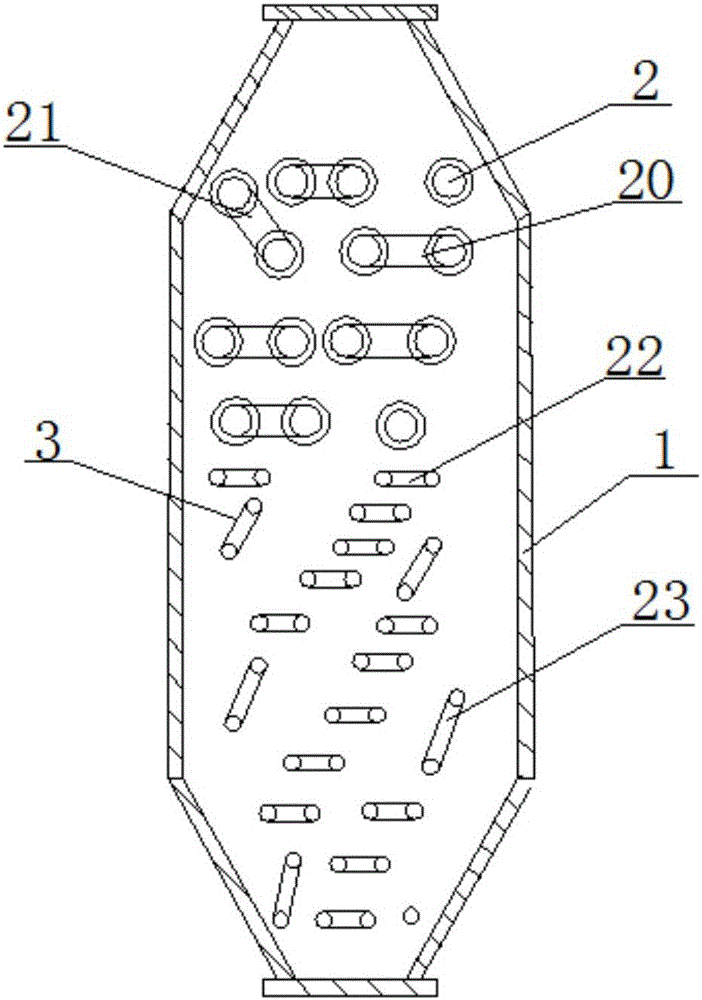

[0019] like Figure 1-3 As shown in the figure, a heat exchanger for waste heat recovery of a coal-fired boiler includes a box body 1, a finned tube 2 arranged at the upper end of the box body 1, and a light tube 3 arranged below the finned tube 2. The box The outer side of the body 1 is provided with a general medium inlet 4 and a general medium outlet 5, the medium inlet of the finned tube 2 and the medium inlet of the light pipe 3 are respectively connected with the general medium inlet 4, the medium outlet of the fin 2 tube and the light pipe are respectively connected. The medium outlet of 3 is respectively connected with the general medium outlet 5, the box body 1 is provided with a smoke temperature measuring point, and the finned t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com