Continuous self-cleaning oil-water separation device

An oil-water separation device and self-cleaning technology, applied in separation methods, liquid separation, grease/oily substance/float removal devices, etc., can solve the problems of large geometric volume, low separation accuracy, and complicated manufacturing, and achieve the geometric volume of the device. Small, low separation energy consumption, the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

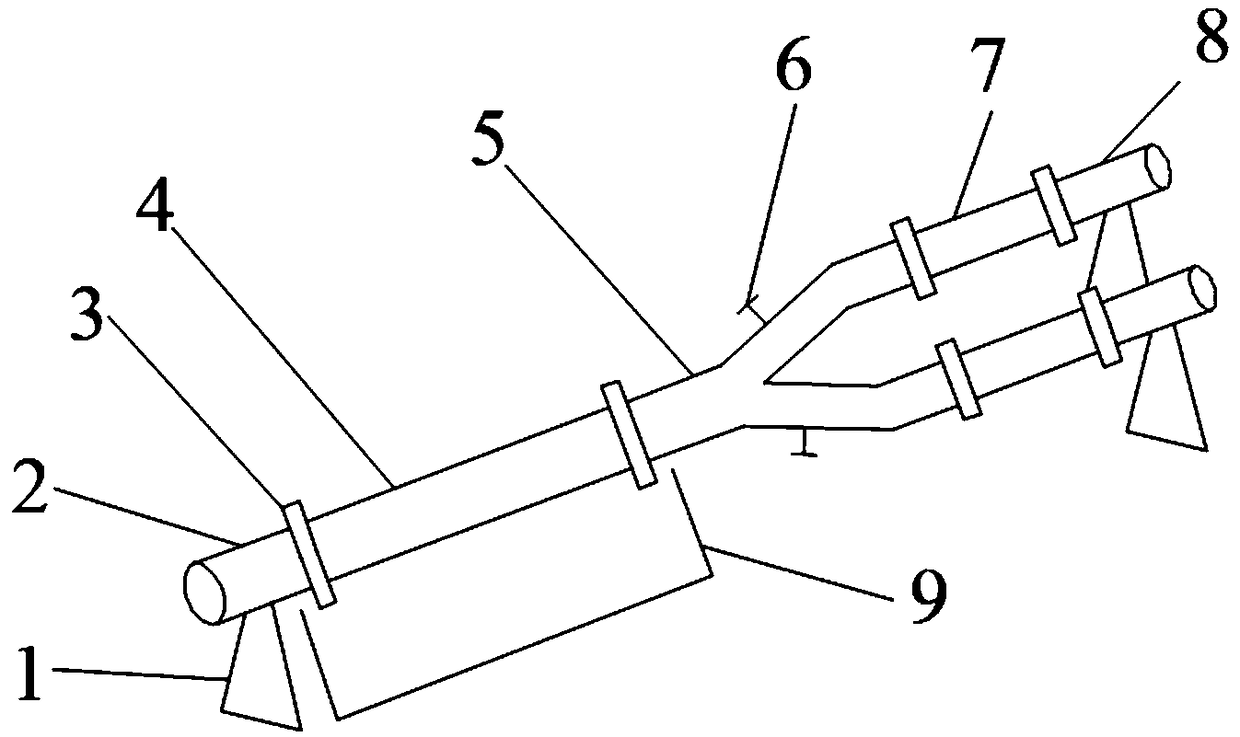

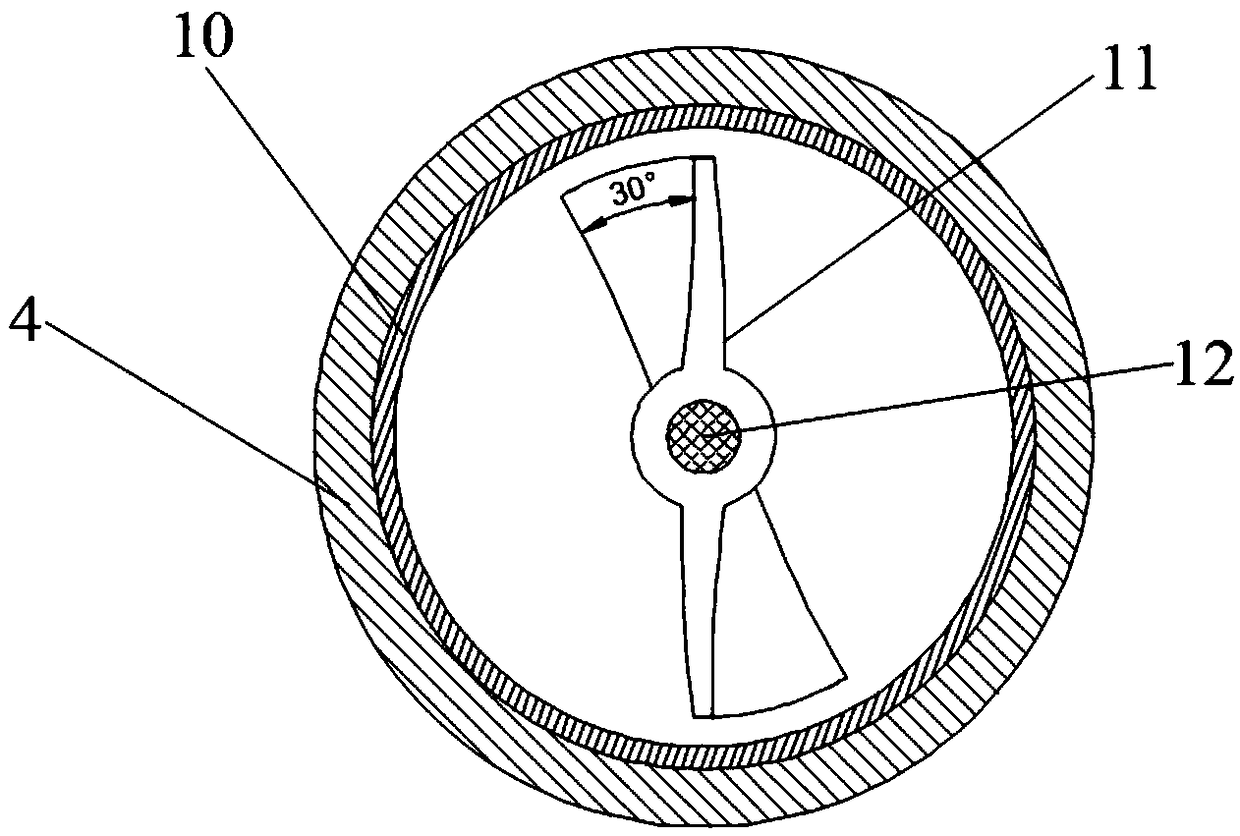

[0025] A high-efficiency continuous self-cleaning oil-water separation device of the present invention mainly includes a bracket 1, a liquid inlet pipe 2, a flange 3, a coating material 4, a shunt pipe 5, a valve 6, a multi-stage structure absorbent cotton 7, a liquid discharge pipe 8, Separation liquid collection box 9, stainless steel mesh 10, fluid-driven rotor 11, steel wire rope 12, position sensor 13, controller 14, electromagnetic limit device 16, and fixture 15, such as figure 1 and figure 2 shown. The stainless steel mesh 10 is connected with the liquid inlet pipe 2 and the shunt pipe 5 through the flange 3, and the stainless steel mesh 10 is coated with a certain thickness and a cladding material 4 with a certain strength, and a separating liquid collection box 9 is placed below, and two shunt pipes 5 ( or multiple) branch pipes are equipped with valves 6 respectively, and the multi-stage structure absorbent cotton 7 is connected with the shunt pipe branch pipe and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com