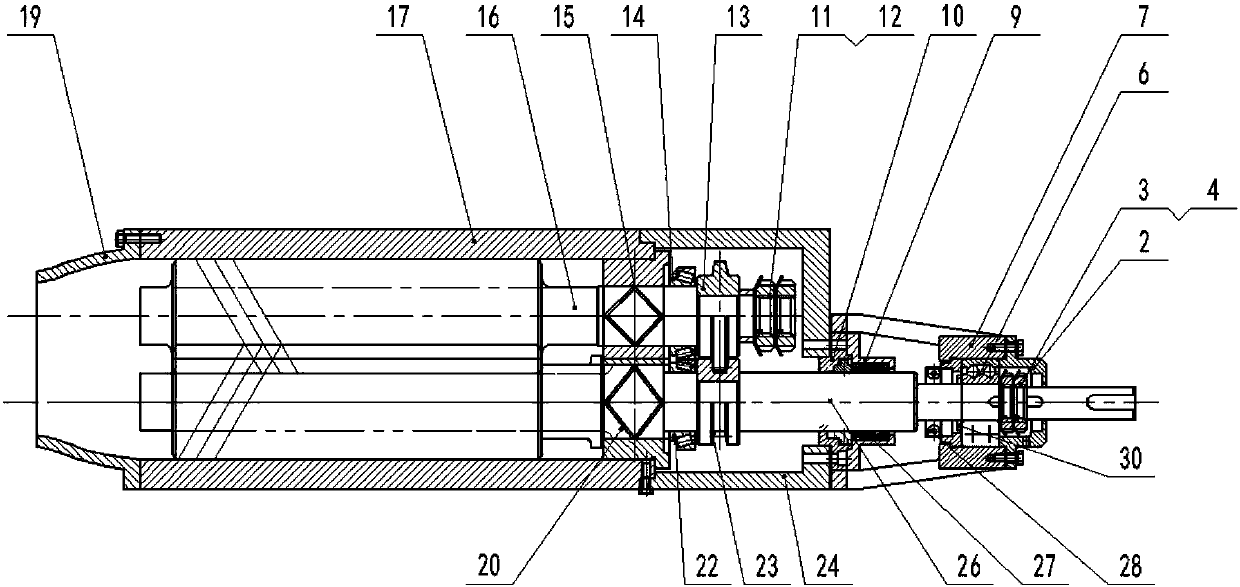

A cantilever twin-screw water jet propulsion pump

A water-jet propulsion, twin-screw technology, applied in the field of machinery, can solve the problems of large power loss, complicated reversing, inconvenient maintenance, etc., and achieve the effects of small mechanical vibration, improved hydraulic efficiency, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

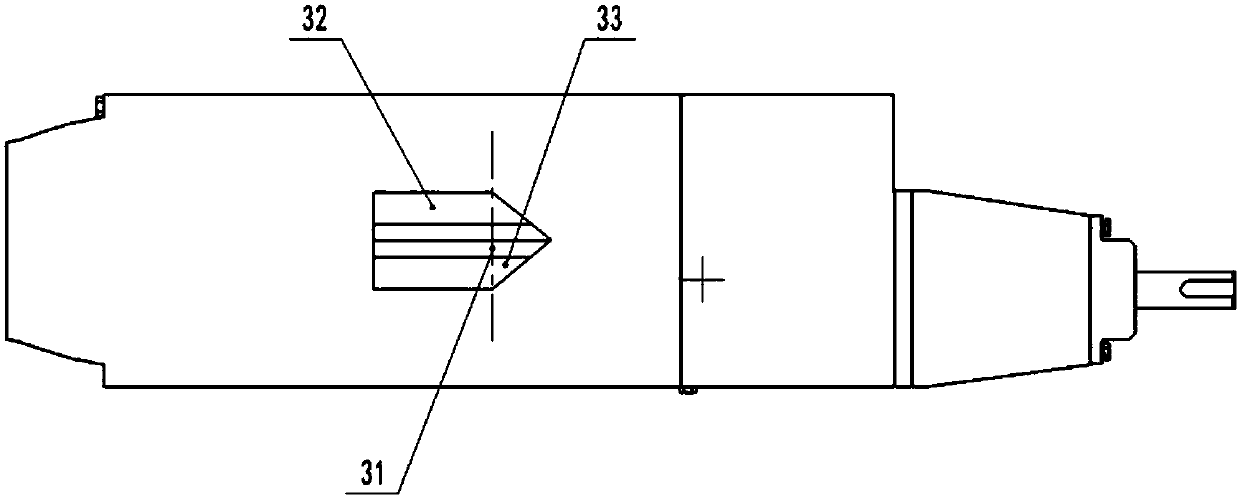

[0035] When the pump is running, due to the pressure difference, the medium flows into the suction port of the twin-screw through the water inlet 31, and the medium flowing into the twin-screw makes the screw and the inner wall of the pump through the rotation of the two intermeshing main screw 26 and the slave screw 16. The volume of the formed sealed cavity changes to form a pressure difference, so that the medium is delivered to the nozzle 19. Since the nozzle 19 is a tapered nozzle with a smaller cross-sectional area than the inlet 31, a high-speed medium flow is formed, thereby forming a reaction force to push the carrier in the medium forward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com