Polymerization reaction device for preparing polylactic acid

A technology of polymerization reaction and polylactic acid, which is applied in the field of polymerization reaction device for the preparation of polylactic acid, can solve the problems of large stirring kinetic energy, complicated granulation process, difficulty in removing non-polymer monomers, etc., achieve uniform distribution of temperature field, reduce The effect of the granulation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

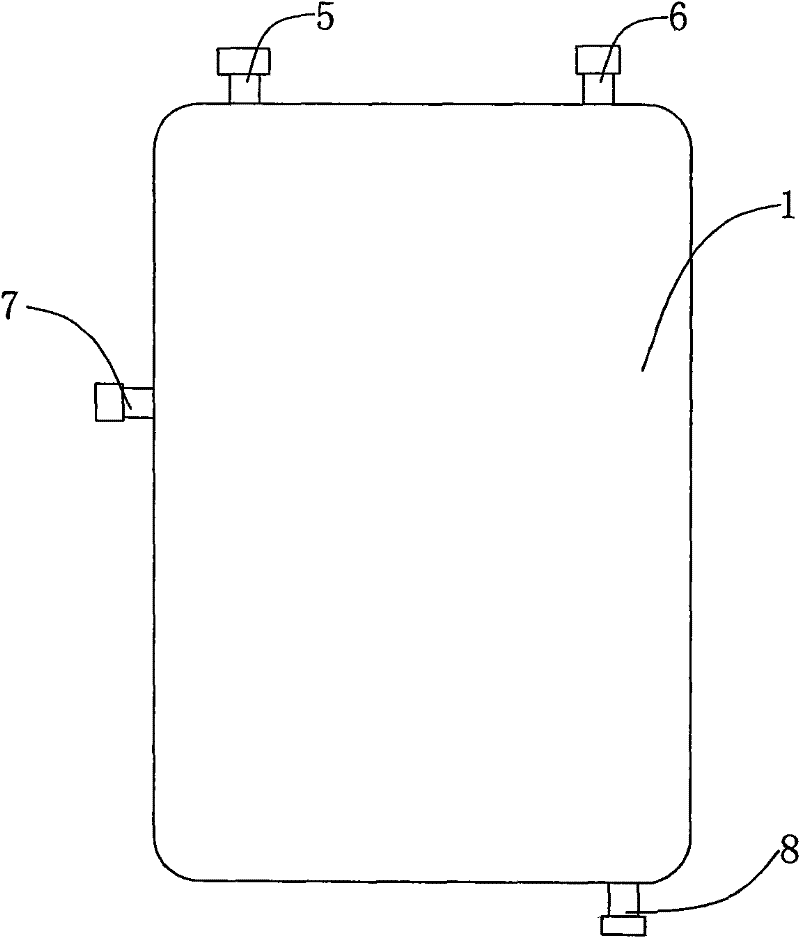

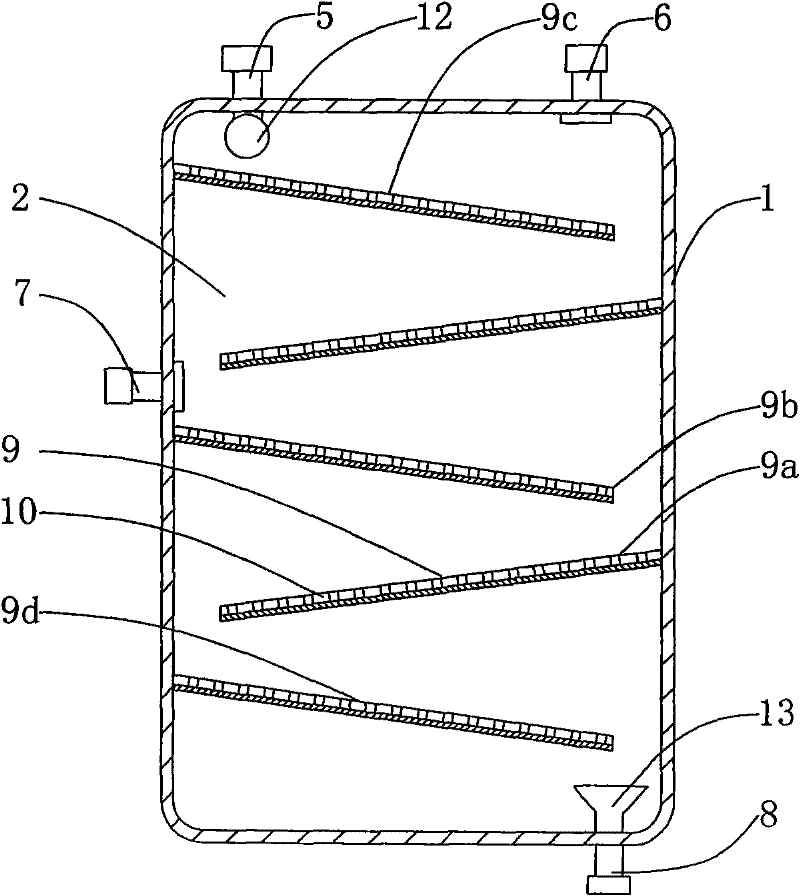

[0028] The polymerization reaction device used to prepare polylactic acid in this embodiment is as follows: figure 1 and Figure 1A As shown, a housing 1 is included, and the inner cavity of the housing 1 constitutes a sealed reaction chamber 2 . A feed port 5 communicating with the reaction chamber 2 is provided on the upper surface of the housing 1, and an air suction port 6 communicating with the reaction chamber 2 is provided on the top of the housing 1, and the outer end of the air extraction port 6 is connected to a vacuum pump. An air inlet 7 communicating with the reaction chamber 2 is provided on the side wall or bottom of the housing 1 , and the outer end of the air inlet 7 is connected to a gas source. A discharge port 8 communicating with the reaction chamber 2 is provided at the bottom of the housing 1 .

[0029] When the air inlet 7 is closed and the gas extraction port 6 is working, the reaction chamber 2 can be in a high vacuum state. The outer end of the ga...

Embodiment 2

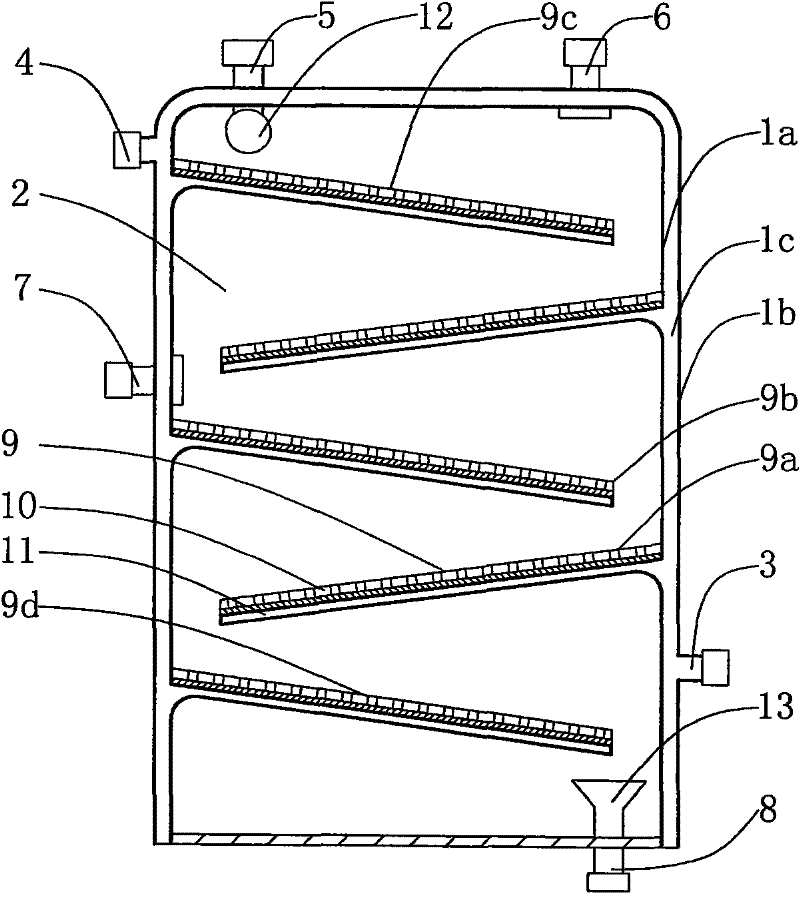

[0038] Preferred embodiments of the present invention are figure 2 As shown, the casing 1 in this embodiment is composed of an inner casing 1a and an outer casing 1b. Between the inner shell 1a and the outer shell 1b is formed a sealed interlayer 1c through which a heating medium or a cooling medium flows. The inside of the inner shell 1a constitutes a sealed reaction chamber 2 . One side of the outer casing 1b is provided with an inlet 3 communicating with the sealed partition 1c. The inlet 3 is used to feed refrigerant or heat medium into the sealed partition 1c to control the temperature condition of the reaction chamber 2. On the upper part corresponding to the other side of the outer shell 1b, an outlet 4 communicating with the sealed compartment 1c is provided. The inlet 3 and the outlet 4 are arranged diagonally to facilitate convection of the refrigerant or heat medium in the sealed compartment 1c.

[0039] A feed port 5 communicating with the reaction chamber 2 is ...

Embodiment 3

[0046] Another preferred embodiment of the present invention is Figure 4 As shown, the housing of the polymerization reaction device in this embodiment is detachably and hermetically connected by an upper part housing and a lower part housing through threads. The upper part of the shell and the lower part of the shell are respectively made with a sealing partition 1c composed of an inner shell 1a and an outer shell 1b. The inner casing 1 a of the upper part casing and the inner casing 1 a of the lower part casing form a sealed reaction chamber 2 . The sealing interlayer 1c of the upper part of the housing is provided with a first introduction port 3a and a first outlet 4a arranged diagonally with the first introduction port 3a; the sealing interlayer 1c of the lower part of the housing is provided with a second An inlet 3b and a second outlet 4b arranged diagonally to the second inlet 3b.

[0047] A feed port 5 communicating with the reaction chamber 2 is provided on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com