Exhaust gas temperature control system

A technology of exhaust temperature and control system, which is applied in the direction of exhaust device, muffler device, engine components, etc. It can solve the problem that it is difficult to meet the exhaust emission control requirements of diesel engines, the exhaust temperature cannot reach 250°C, and the conversion efficiency of the post-treatment system is low. and other issues to achieve the effect of reducing cost and power consumption, reducing dependence, and reducing pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

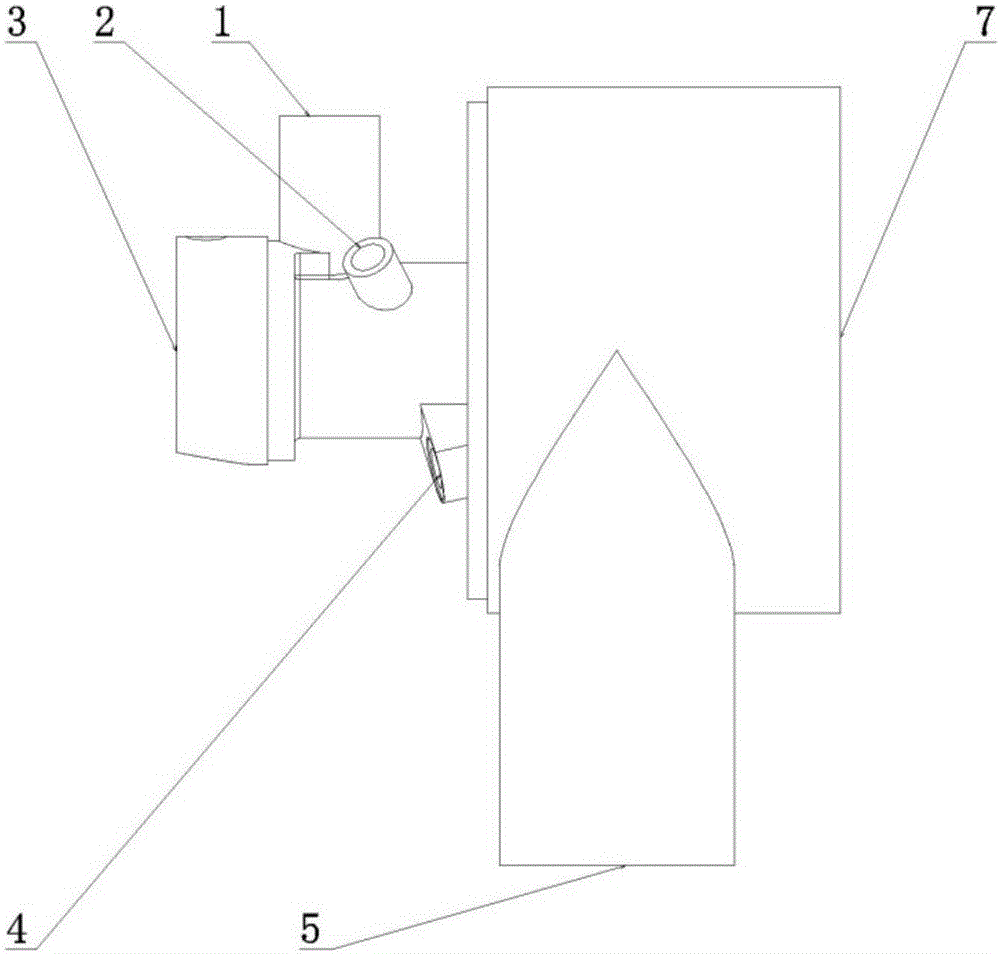

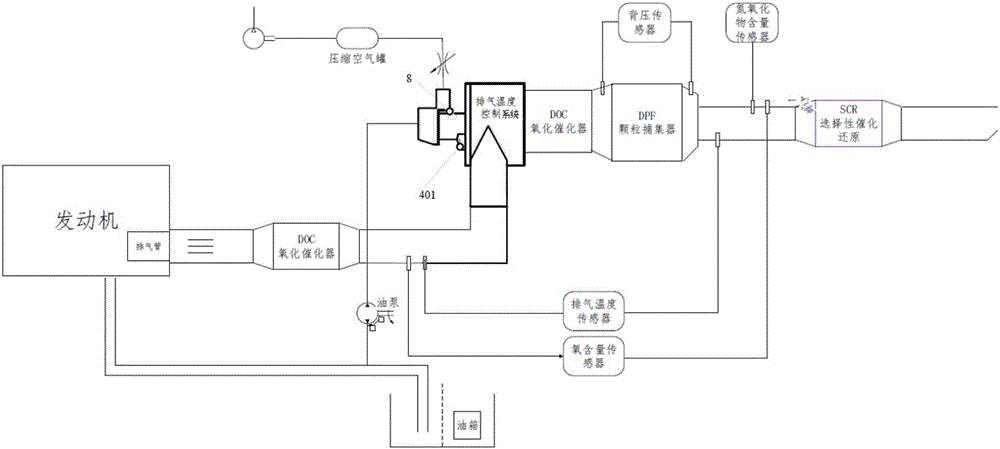

[0029] Such as figure 1 -2, a kind of exhaust temperature control system is used in the automobile after-treatment system to increase the exhaust temperature of the automobile, including an oil-gas mixing unit, a burner 6 and an exhaust chamber 12 arranged in sequence,

[0030] The oil-air mixing unit includes an oil-air mixing chamber, a fuel injector 3, a first-layer atomizer 9 and a second-layer atomizer 10. In the chamber, the auxiliary air inlet 1 and the glow plug hole 2 are all arranged on the oil-air mixing chamber, and the fuel injector 3 is connected with the fuel tank of the automobile through an electronically controlled oil pump.

[0031] When the oil-air mixing unit is working, a heating plug 8 is inserted into the glow plug hole 2 to heat the oil ejected from the injector 3, making the oil easier to be atomized, and then the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com