Hydrophobic bacteriostasis multifunctional coated cloth and processing method thereof

A multi-functional coating and hydrophobic coating technology, applied in the field of coated cloth, can solve the difficulty of uniform coating of waterproof materials and antibacterial materials, the deterioration of softness and mechanical properties of coated cloth, and affect the normal use of coated cloth and other problems, to achieve good anti-light corrosion performance, excellent antibacterial performance, and not easy to breed bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

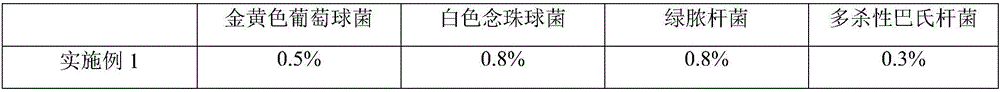

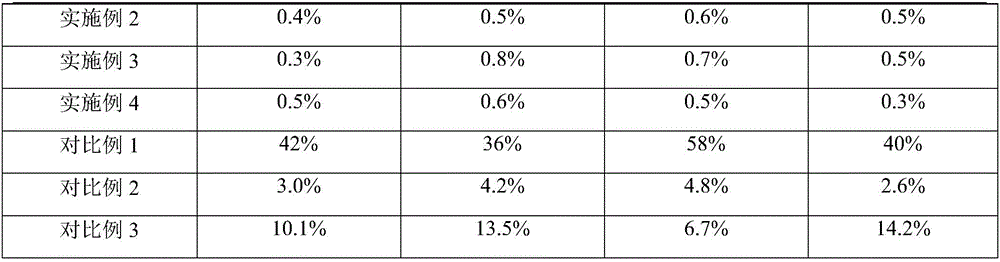

Examples

Embodiment 1

[0031] A kind of hydrophobic and antibacterial multifunctional coated cloth, the multifunctional coated cloth comprises warp knitted fabric, antibacterial coating coated on the surface of warp knitted cloth and antibacterial coating coated on the top of the warp knitted fabric from bottom to top. Hydrophobic coating;

[0032] Wherein, the bacteriostatic coating is made from the following raw materials: 20kg of bamboo fiber, 2kg of horseradish extract, 2kg of wax gourd kernel extract, 20kg of polyvinylidene chloride emulsion, compound emulsion of acrylate copolymer and paraffin (weight ratio 1: 1) 35kg,

[0033] The hydrophobic coating is made from the following raw materials: 100kg of PVC paste resin, 50kg of a mixture of synthetic vegetable ester and dioctyl phthalate at a weight ratio of 1:1, 2kg of calcium stearate, 40kg of hydrophobic nanofibers; The fiber is a titanium dioxide fiber with a length of about 1 mm and a diameter of about 0.1 μm;

[0034] Titanium dioxide fi...

Embodiment 2

[0040] A kind of hydrophobic and antibacterial multifunctional coated cloth, the multifunctional coated cloth comprises warp knitted fabric, antibacterial coating coated on the surface of warp knitted cloth and antibacterial coating coated on the top of the warp knitted fabric from bottom to top. Hydrophobic coating;

[0041] Wherein, the bacteriostatic coating is made from the following raw materials: bamboo fiber 16kg, horseradish extract 2kg, wax gourd kernel extract 2kg, polyvinylidene chloride emulsion 20kg, compound emulsion of acrylate copolymer and paraffin (weight ratio 1: 1) 35kg,

[0042] The hydrophobic coating is prepared from the following raw materials: PVC paste resin 100kg, epoxy butyl stearate 50kg, calcium stearate 2kg, filler 15kg, magnesium hydroxide 3kg, phenol 1kg, butylhydroxyanisole 1kg, adhesive 2kg, 40kg of hydrophobic nanofibers; the hydrophobic nanofibers are titanium dioxide fibers with a length of 0.5mm and a diameter of 0.1μm;

[0043] Titaniu...

Embodiment 3

[0049] A kind of hydrophobic and antibacterial multifunctional coated cloth, the multifunctional coated cloth comprises warp knitted fabric, antibacterial coating coated on the surface of warp knitted cloth and antibacterial coating coated on the top of the warp knitted fabric from bottom to top. Hydrophobic coating;

[0050] Wherein, the bacteriostatic coating is made of the following raw materials: bamboo fiber 15kg, horseradish extract 0.8kg, wax gourd kernel extract 1kg, polyvinylidene chloride emulsion 35kg, compound emulsion of acrylate copolymer and paraffin (weight ratio 1 : 1) 40kg,

[0051] The hydrophobic coating is prepared from the following raw materials: PVC paste resin 100kg, epoxy octyl stearate 65kg, zinc stearate 4kg, filler 30kg, aluminum hydroxide 10kg, pentachlorophenol 3kg, dibutylhydroxytoluene 2kg, adhesive 5kg of agent, 55kg of hydrophobic nanofibers; the hydrophobic nanofibers are titanium dioxide fibers with a length of 0.5mm and a diameter of 0.5μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com