Demagnetizing and deflective blow preventing device of pipeline welding line

A degaussing and pipeline technology, applied in welding accessories and other directions, can solve the problems of poor welding seam formation, incomplete penetration, arc extinguishing and other problems, and achieve the effect of high pipeline connection strength, ensuring welding quality and reducing construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

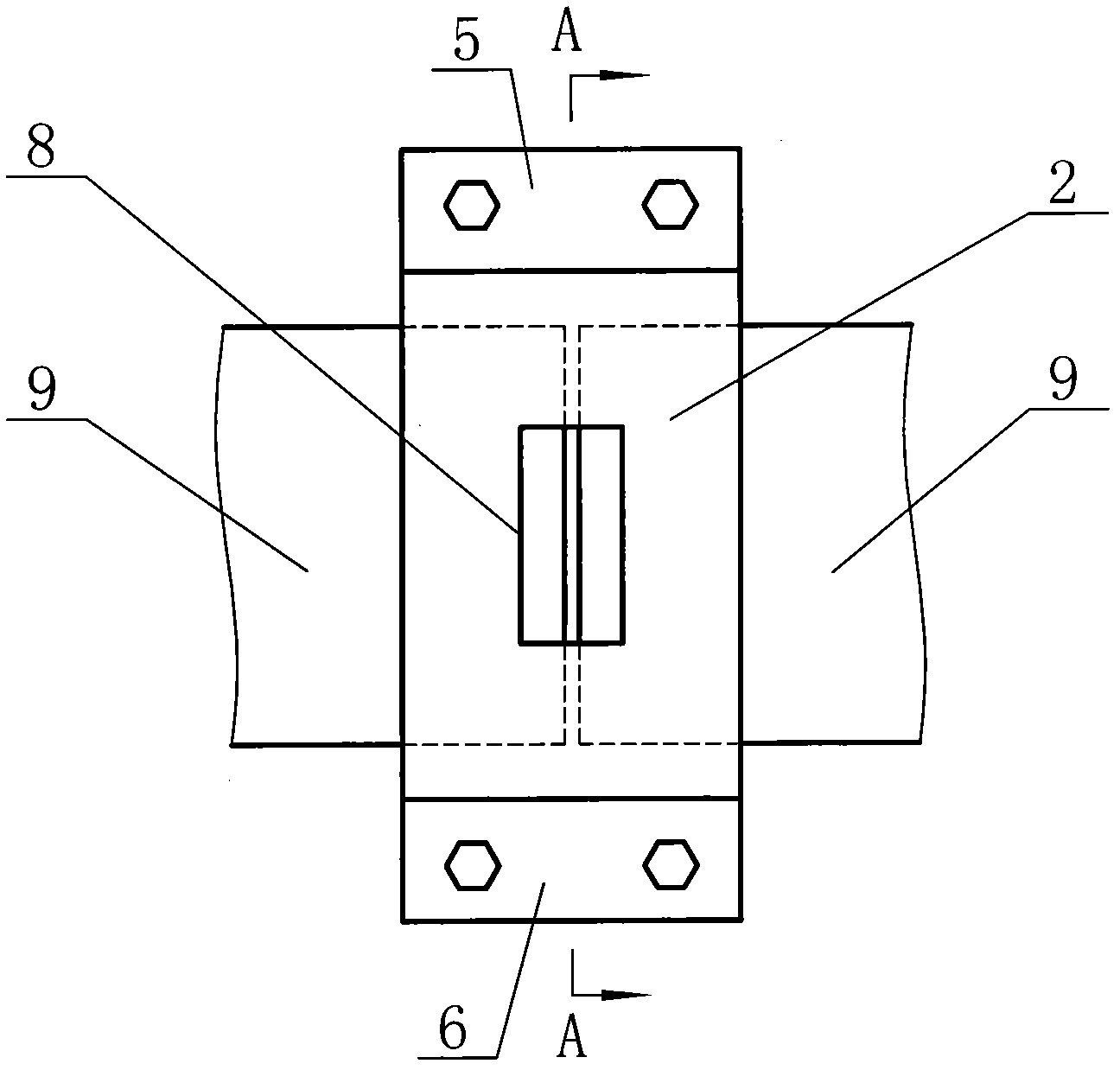

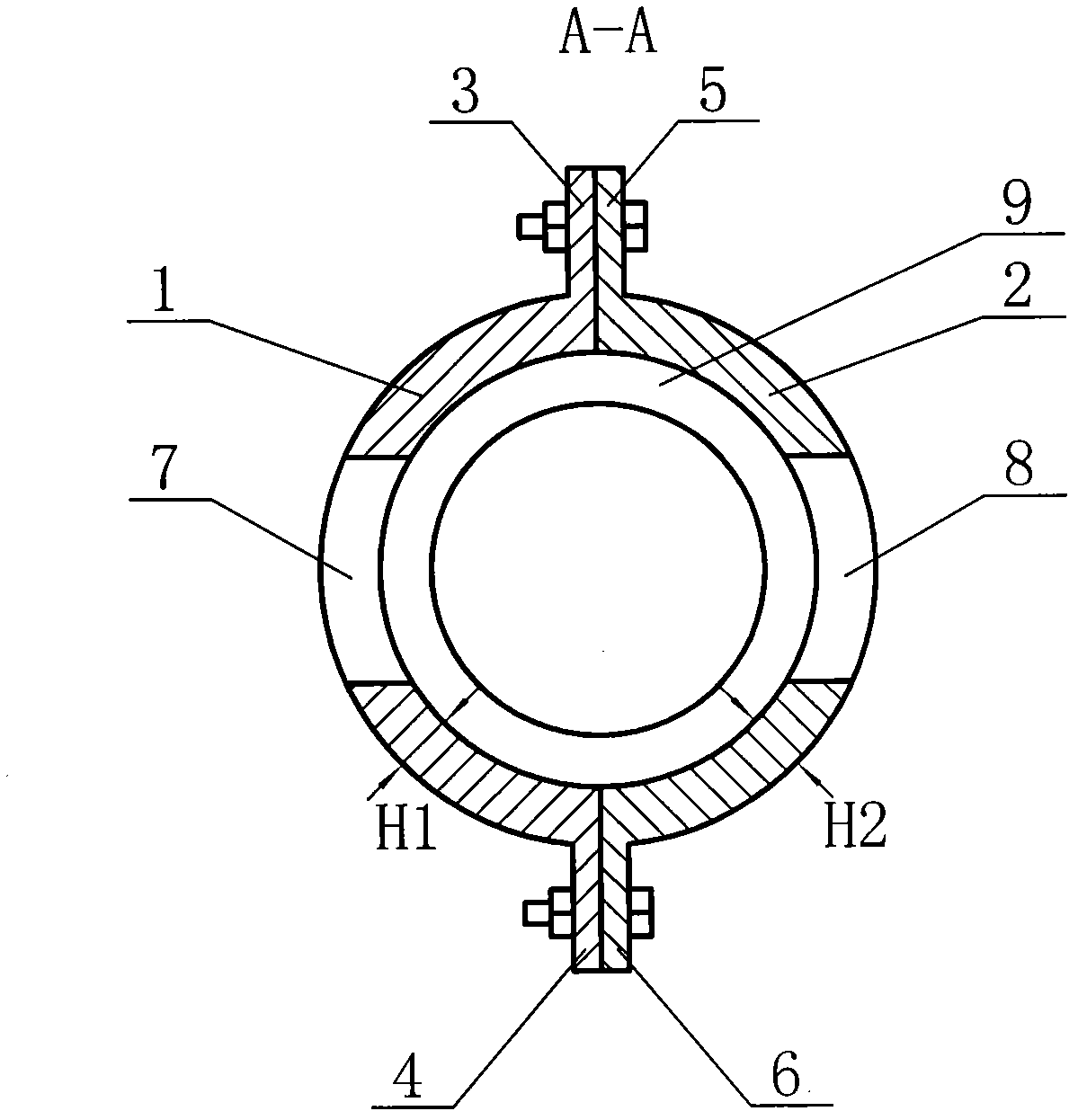

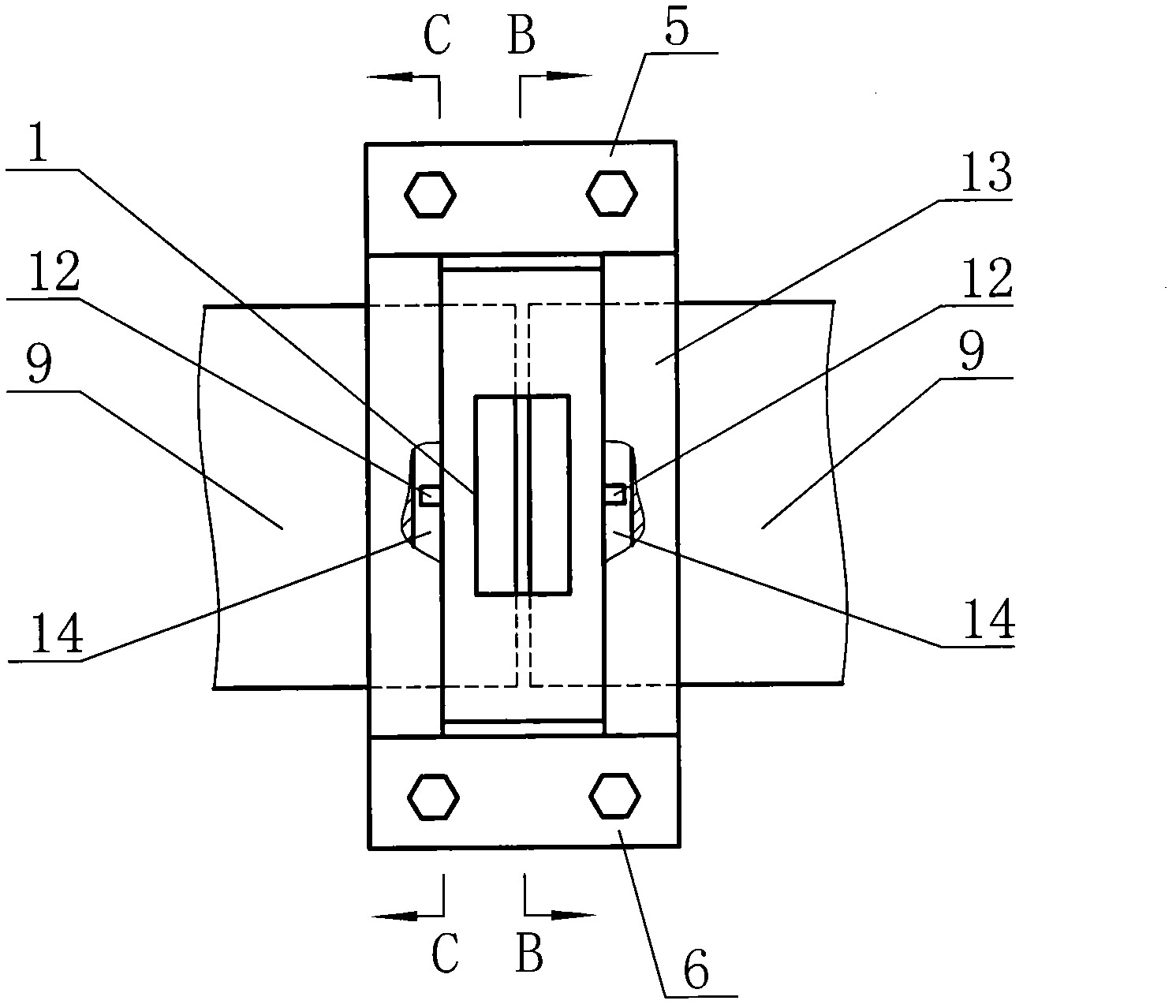

[0007] The pipeline welding seam demagnetization and anti-bias blowing device of the present invention includes a first carbon steel shielding plate 1 and a second carbon steel shielding plate 2. The first carbon steel shielding plate 1 and the second carbon steel shielding plate 2 are both semi-circular arc shapes The first carbon steel shield plate 1 is provided with a first welding port 7, and the second carbon steel shield plate 2 is provided with a second welding port 8. The first carbon steel shield plate 1 and the second carbon steel shield plate 2 pass through the shield plate The connecting devices are connected to each other. The first carbon steel shielding plate 1 and the second carbon steel shielding plate 2 are connected to each other to form a ring-shaped shielding cover. When welding, the shielding cover is placed at the joint of the two pipes 9, and the carbon steel plate itself shields the magnetic field. In order to prevent the partial blow of the welding arc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com