Liquid crystal grating and manufacturing method thereof

A liquid crystal grating and liquid crystal technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of phase modulation curve broadening, phase modulation depth reduction, and diffraction efficiency reduction, achieving suppression of fringe electric fields, high resolution, and large The effect of deflection angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

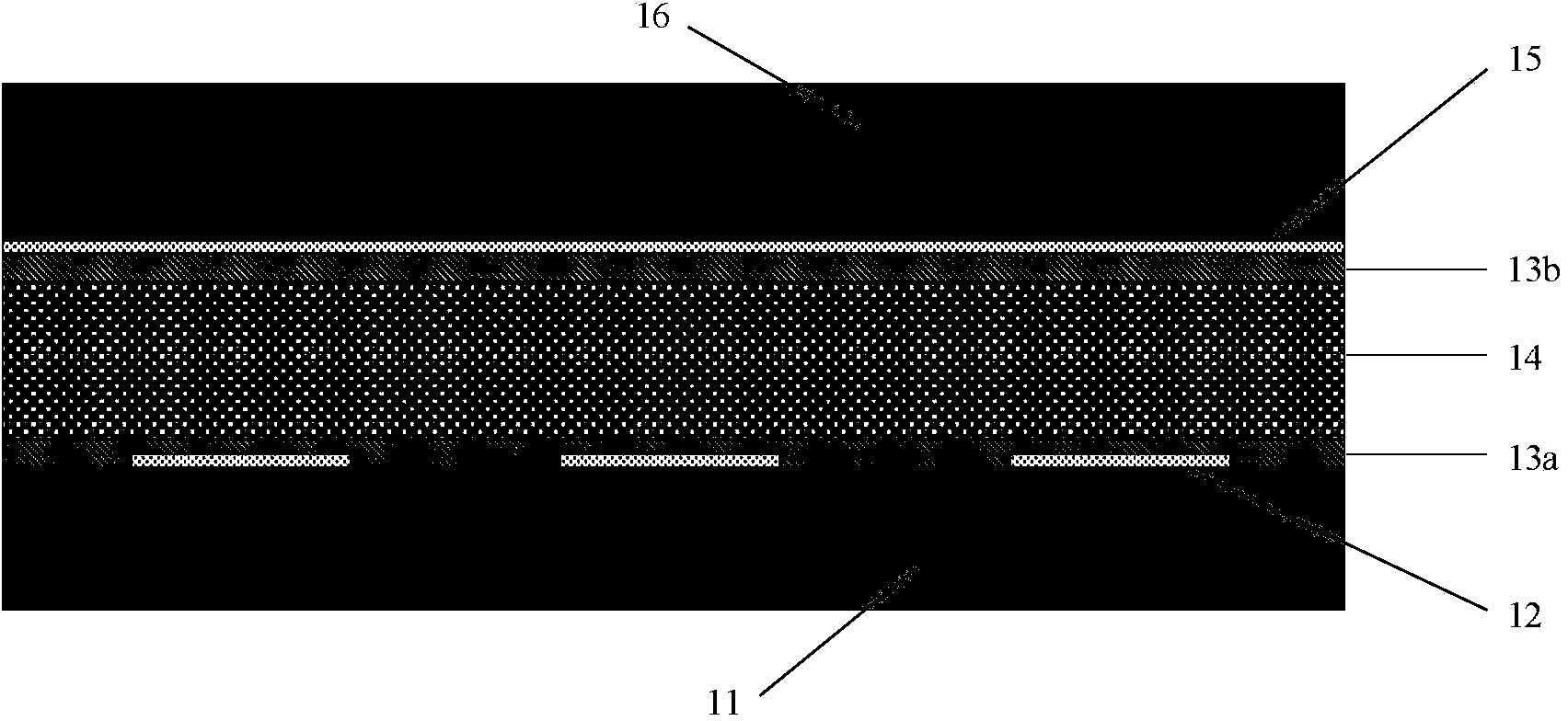

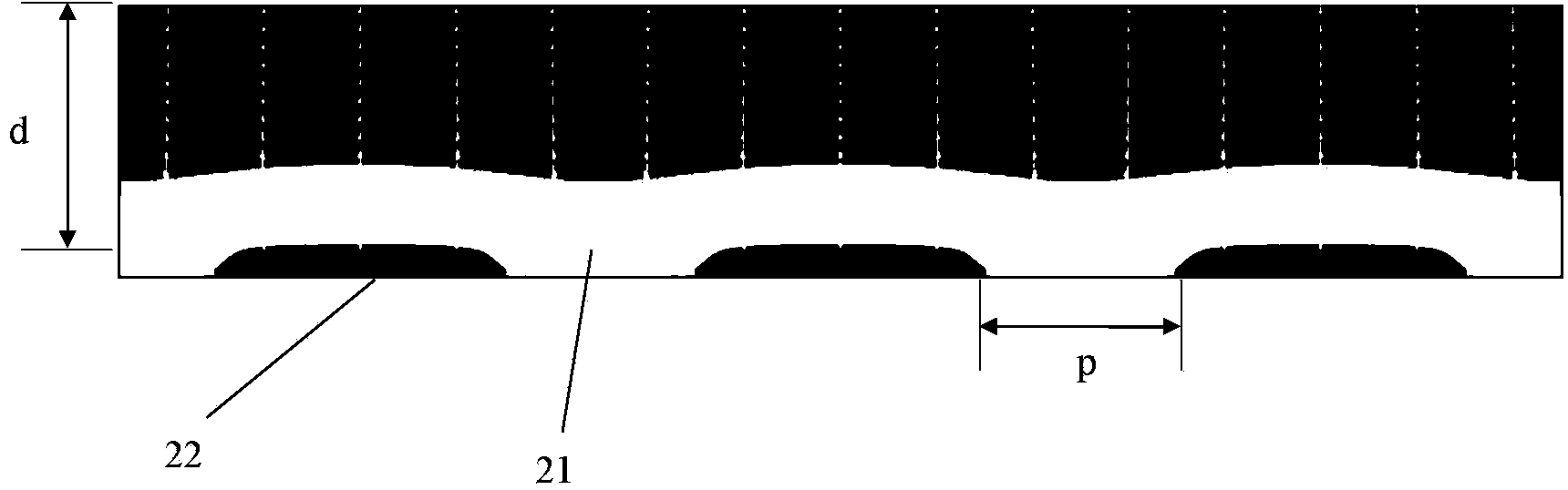

[0042] Figure 6 is a schematic diagram of the cross-sectional structure of the liquid crystal grating of the present invention, such as Figure 6As shown, the present invention proposes a liquid crystal grating, and a liquid crystal 66 is poured between the lower glass substrate 61 and the upper glass substrate 68 . On the lower glass substrate 61, a lower ground electrode 62, an insulating dielectric layer 69a, an address electrode 63, an insulating dielectric layer 69b, an upper ground electrode 64, and a liquid crystal alignment layer 65a are sequentially distributed, and on the upper glass substrate 68, a ground electrode 67 is sequentially distributed. , Liquid crystal alignment layer 65b. In the present invention, indium tin oxide film (ITO) is preferably used as the material of the lower ground electrode 62 , the address electrode 63 , the upper ground electrode 64 , and the ground electrode 67 .

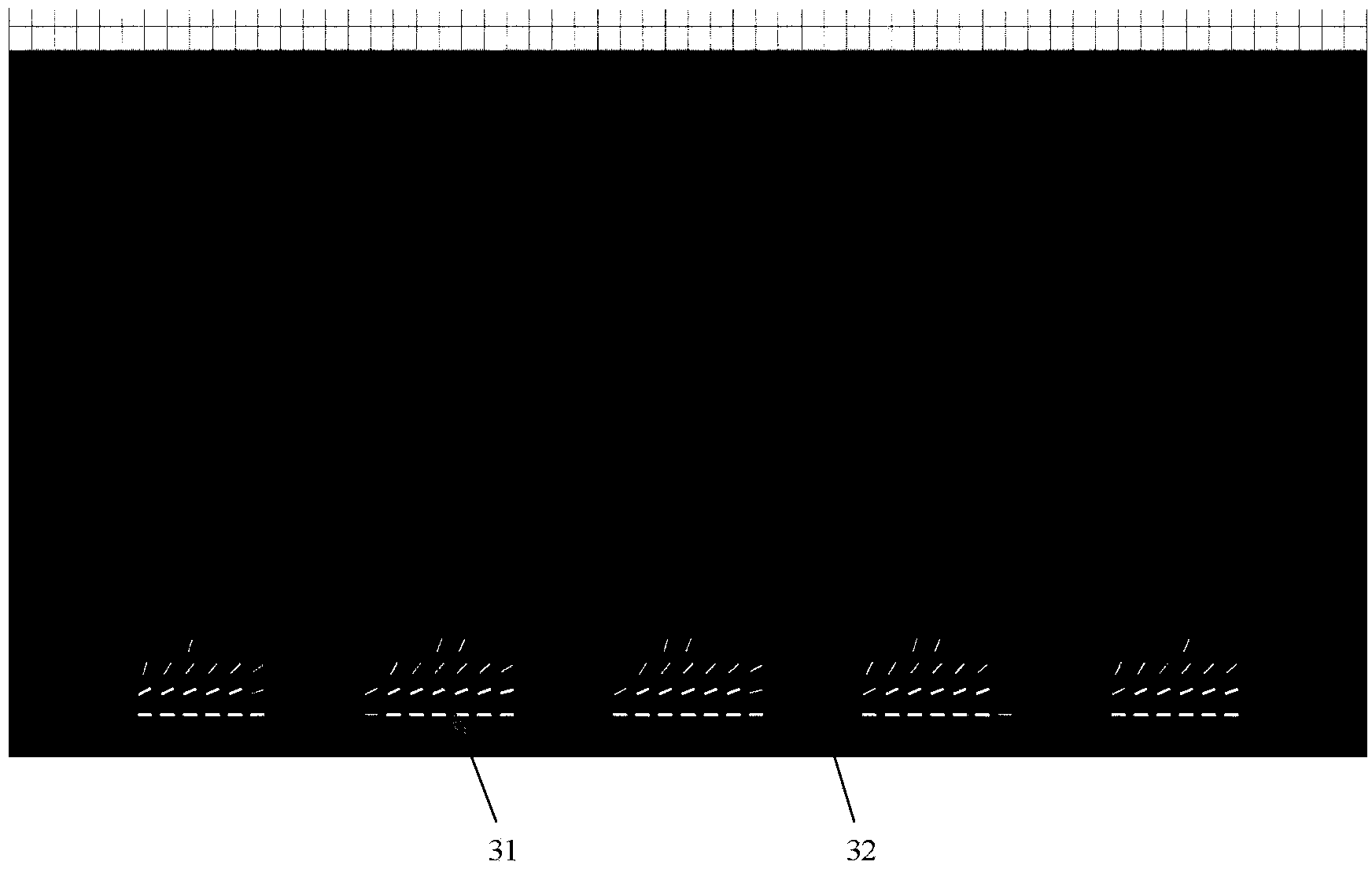

[0043] Figure 7 It is a schematic diagram of the three-dimensional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com