Brush-commutated electric motor

A technology of electric motors and motors, applied in the direction of electric components, DC commutators, electrical components, etc., can solve problems such as electromagnetic interference and interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

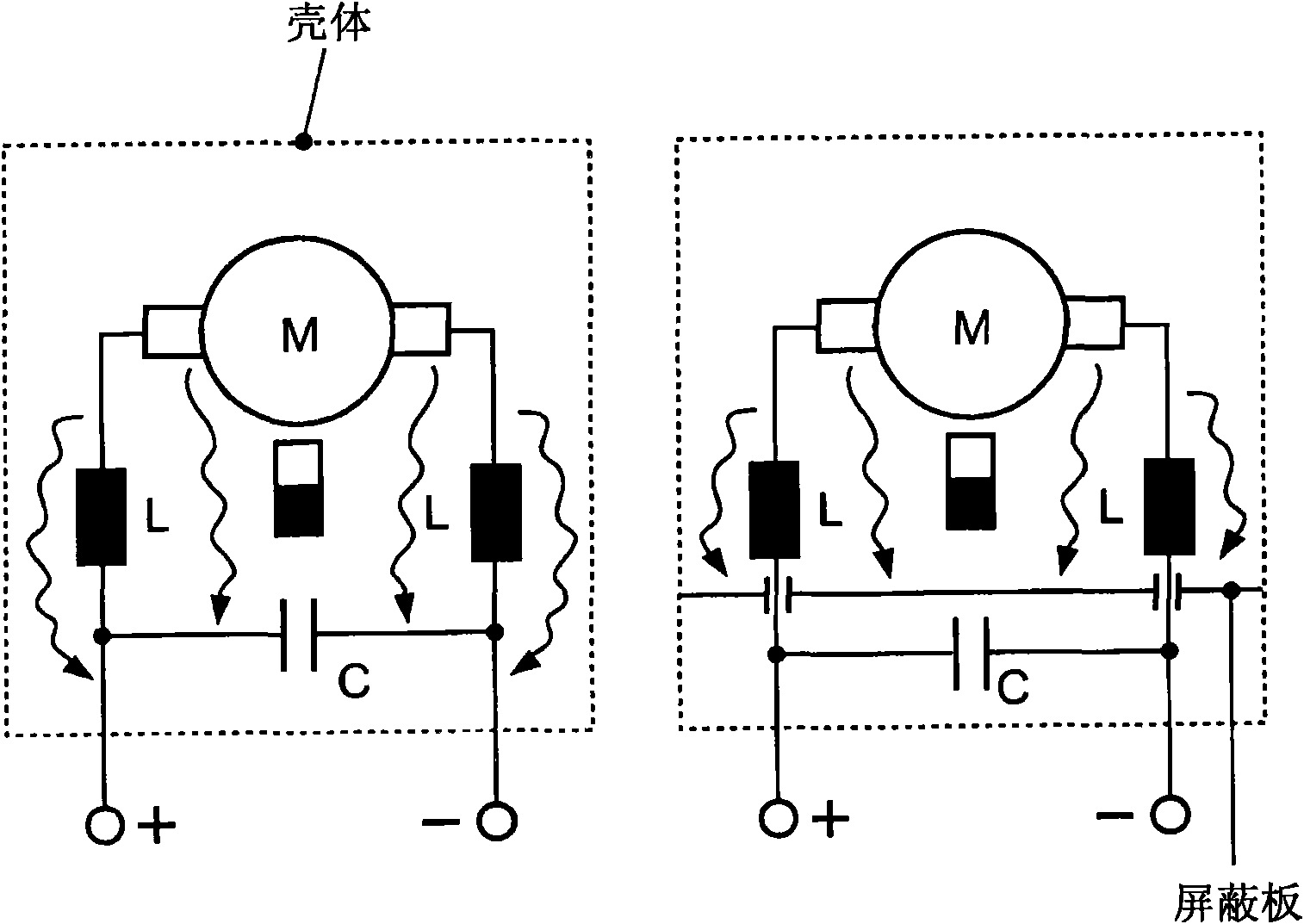

[0015] figure 1 (a) shows a schematic diagram of the working principle of the present invention. Electromagnetic interference is thus generated at the commutator in the electric motor M, which is drawn by a curved arrow. This electromagnetic interference is dissipated on the interference suppression element, which is represented here in a simplified form by a winding L and a capacitor C. In addition, due to the high-frequency part of electromagnetic interference, the interference passes by L and C on the anti-interference component and is also transmitted to circuits other than the electrical components L and C. figure 1 (b) shows a device with a shielding plate according to the invention exactly in a schematic representation. Interference that does not propagate along the line, especially from the area of the commutator, therefore no longer propagates outside the area of the shielded motor. The advantageous aspects of the invention are therefore based on the conclusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com