A kind of gear steel and its production method

A production method and gear steel technology, applied in the field of metallurgical manufacturing, can solve the problems of reducing the fatigue performance of gear steel, oxide inclusions, improvement, etc., and achieve the effect of simple composition, good performance, and refined grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the examples, so as to facilitate a clearer understanding of the present invention, but it is not intended to limit the present invention.

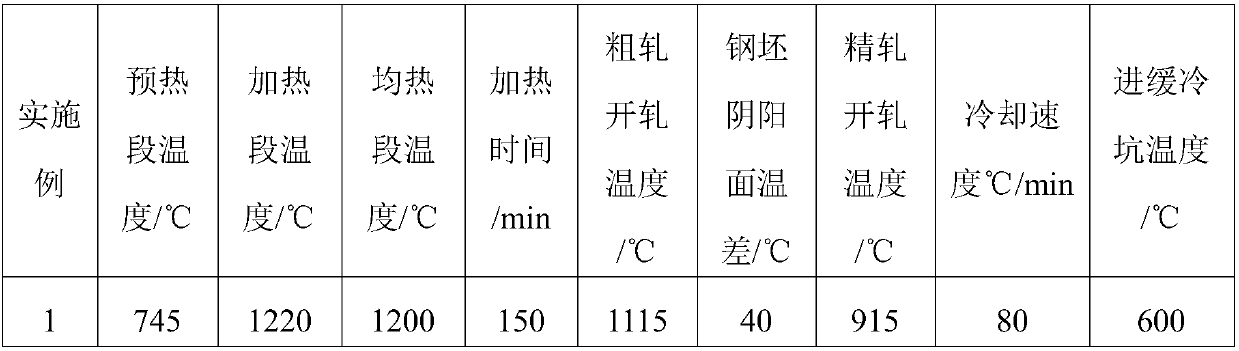

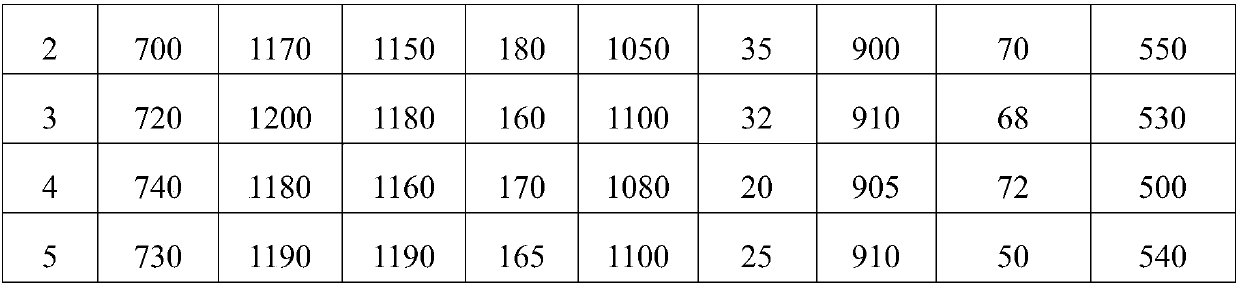

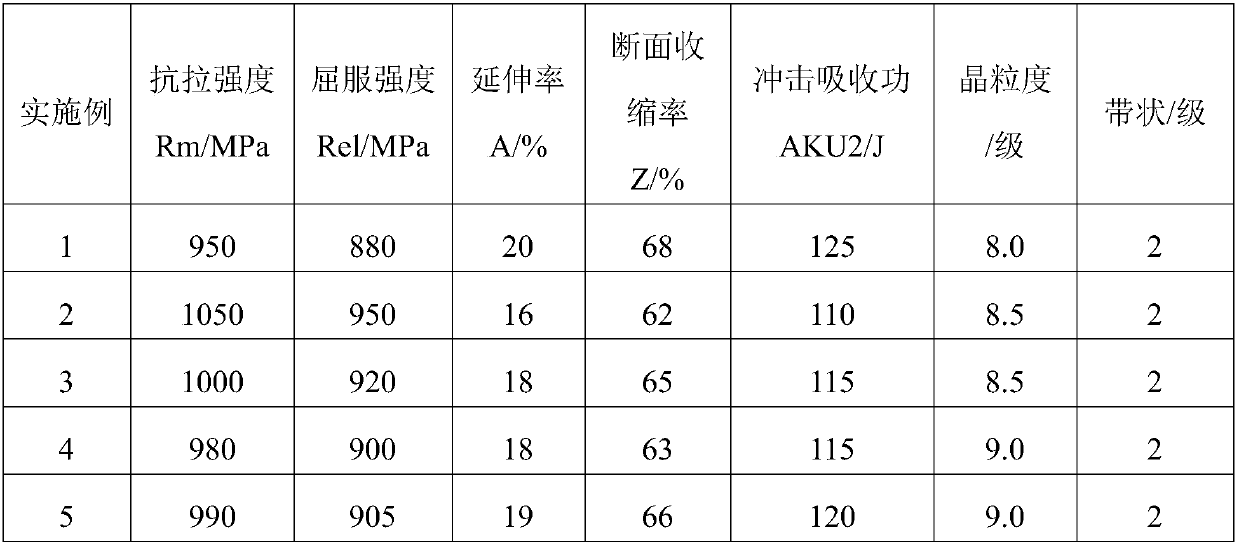

[0027] According to the chemical composition of the present invention, weight percentage and production method requirement, prepare five embodiments, the chemical composition weight percentage of five embodiments is shown in Table 1; Five embodiment production process process parameters are shown in Table 2, and five embodiments obtain The performance parameters of the gear steel are shown in Table 3.

[0028] Table 1 embodiment chemical composition (wt%)

[0029] Example

C

Si

mn

Cr

V

P

S

N

O

1

0.25

0.30

1.40

1.20

0.10

0.010

0.045

0.0120

0.0012

2

0.32

0.25

1.20

1.10

0.05

0.009

0.030

0.0090

0.0008

3

0.30

0.27

1.30

1.15

0.08

0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact absorption energy | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com