A casing type double-sided fluidized bed rapid pyrolysis device

A fluidized bed, thermal cracking technology, applied in special forms of dry distillation, direct heating dry distillation, energy input, etc., can solve the problems of blow-by gas, combustion reaction products, etc., to improve the average temperature difference, promote heat transfer, and high heat transfer efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

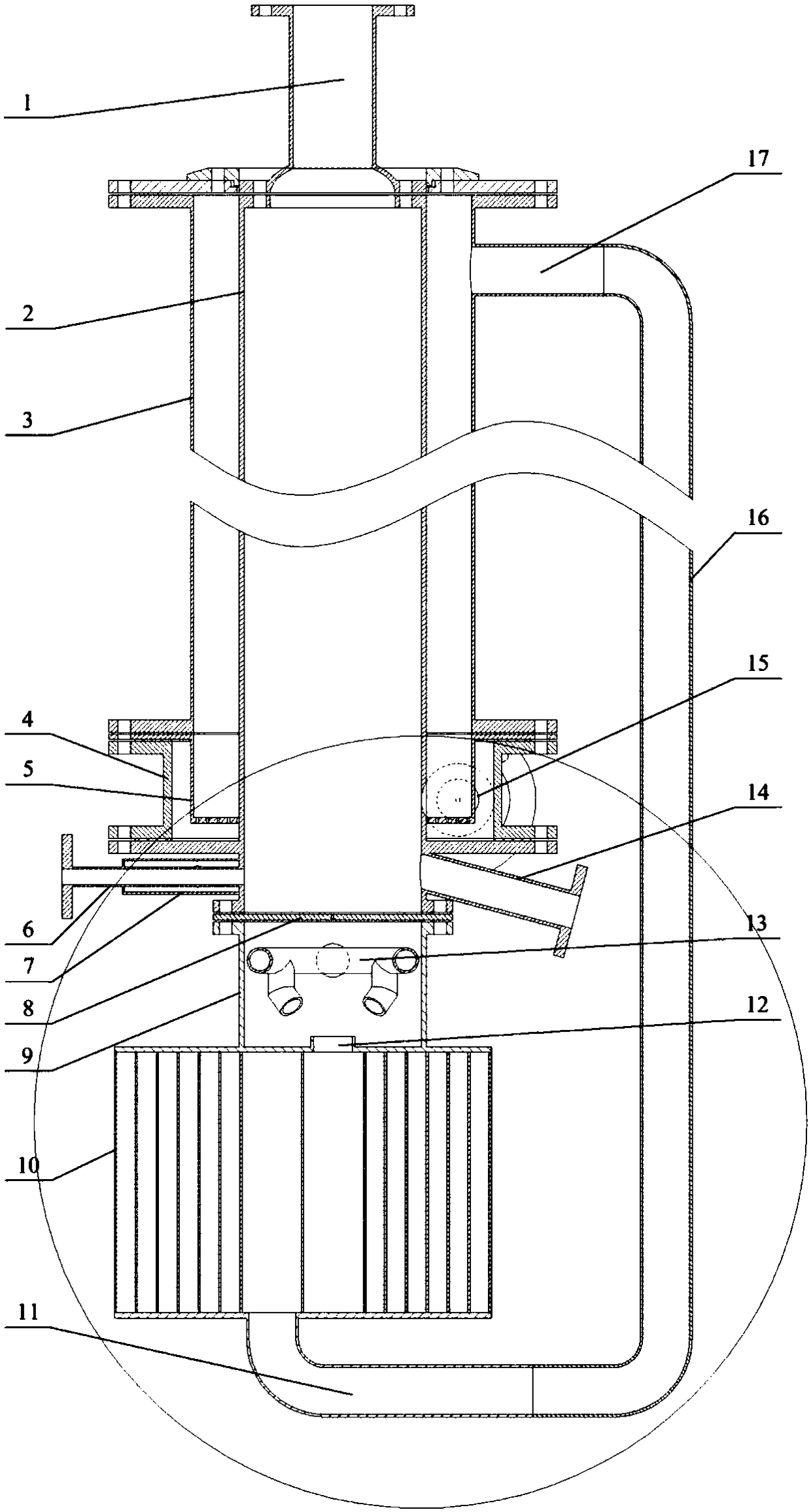

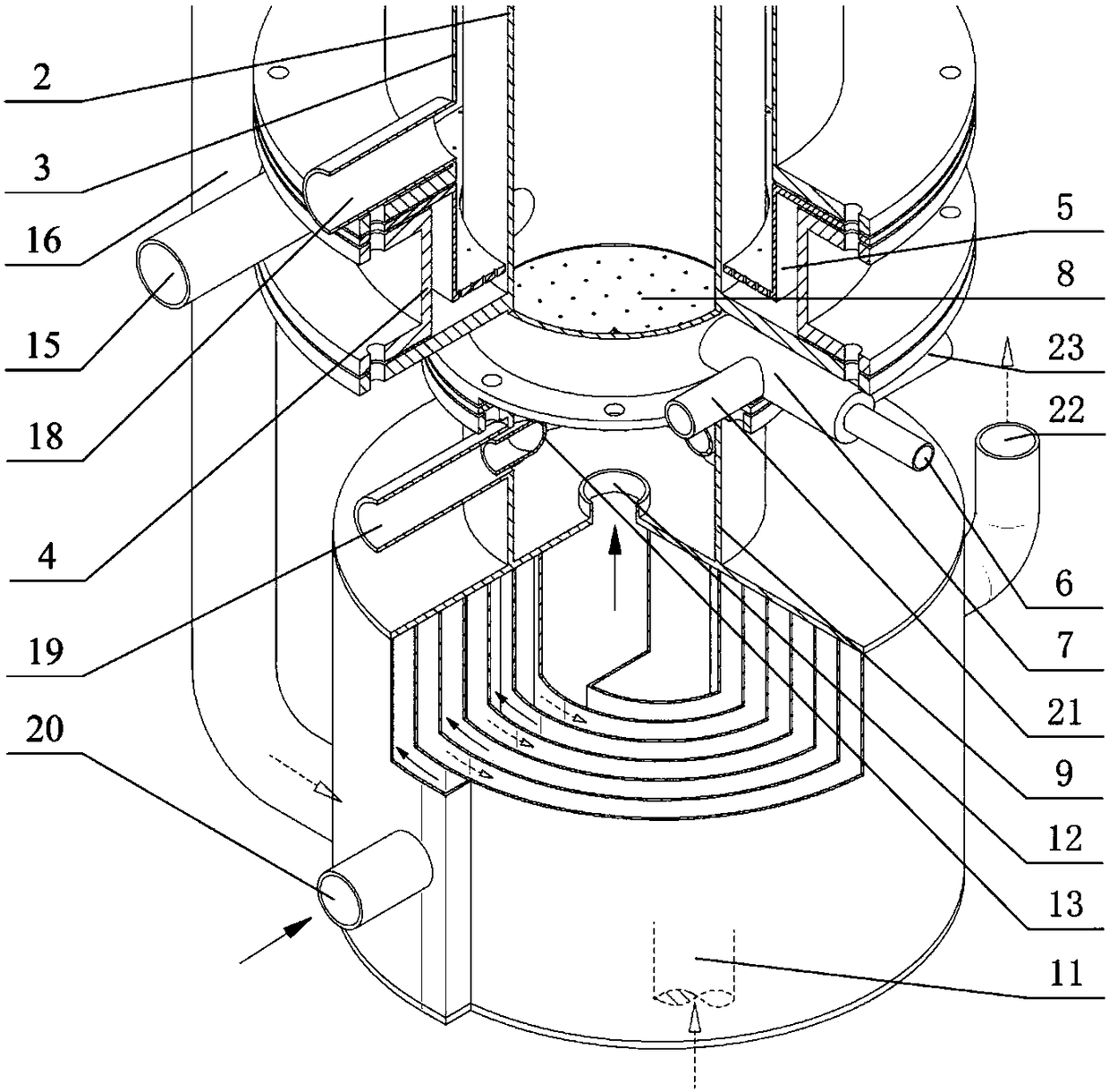

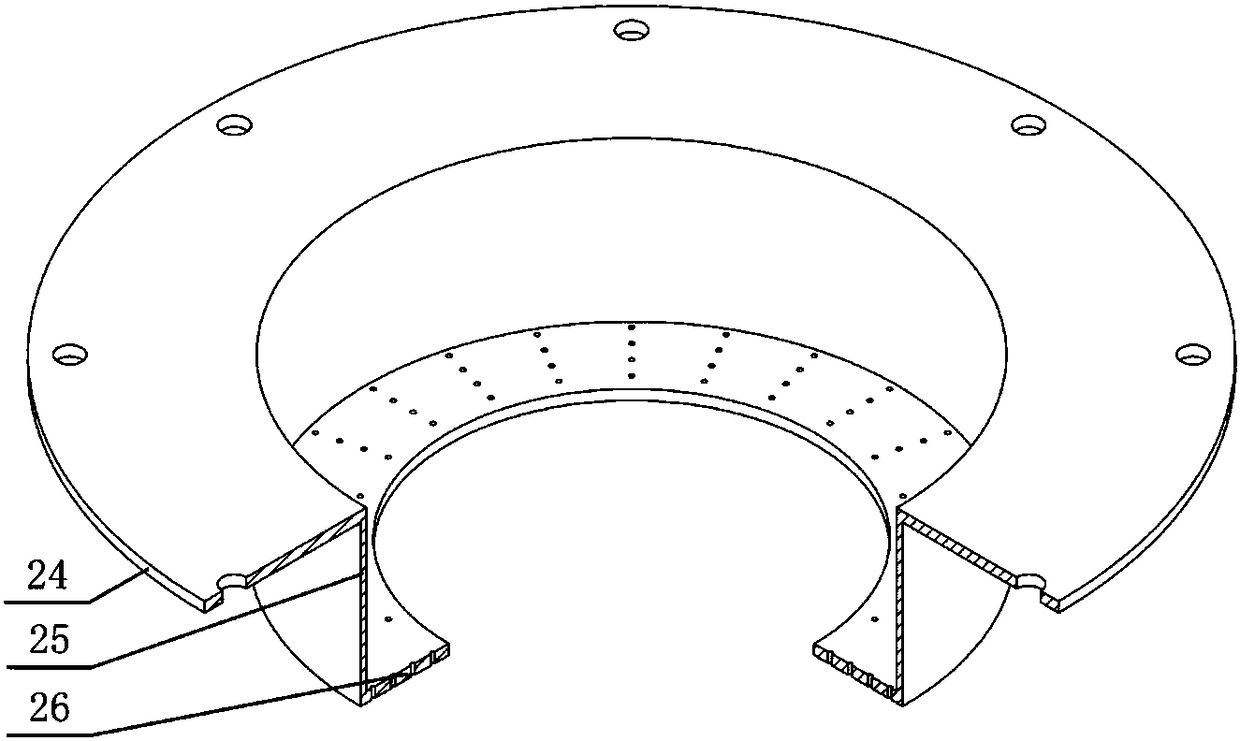

[0016] The casing type double-sided fluidized bed rapid pyrolysis device that the present invention proposes, its structure is as follows figure 1 As shown, it includes: inner tube 2 , outer tube 3 , support sleeve 4 , annular air distribution plate 5 , circular air distribution plate 8 , buffer sleeve 9 , carrier gas distributor 13 and spiral plate heat exchanger 10 . Inner pipe 2, outer pipe 3, support sleeve 4, annular air distribution plate 5, circular air distribution plate 8, buffer sleeve 9 and spiral plate heat exchanger 10 are installed coaxially from top to bottom in sequence.

[0017] Such as figure 1 As shown, an annular cavity is formed between the outer tube 3 and the inner tube 2, the annular cavity between the outer tube 3 and the inner tube 2 is a heating zone, the space in the inner tube is a reaction zone, and the heating zone and the reaction zone are respectively Filled with bed materials, the side wall of the outer tube 3 is provided with a heating zone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com