Flame retardation polypropylene insulation cable material and preparation method thereof

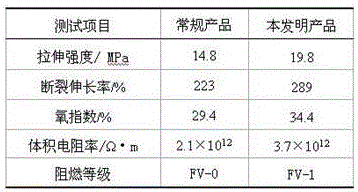

A technology for flame-retardant polypropylene and insulated cables, which is applied in the direction of insulated cables, insulators, and insulated conductors. good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Example 1 Flame-retardant polypropylene insulating cable material, mainly prepared from the following raw materials (5kg each): 107 parts of polypropylene, 5 parts of white carbon black, 3 parts of sulfur, 4 parts of zinc borate, 6 parts of calcium stearate, carboxymethyl 6 parts of sodium cellulose, 5 parts of epoxidized soybean oil, 17 parts of aluminum hydroxide, 10 parts of diatomaceous earth, and 8 parts of lignin. The preparation method of above-mentioned flame-retardant polypropylene insulating cable material is:

[0024] (1) Mix aluminum hydroxide and diatomaceous earth, add water 0.4 times the mass of raw materials, pulverize for 30 minutes, pass the slurry through a 200-mesh sieve, dry and pulverize, and make powder;

[0025] (2) Mix white carbon black, sulfur, zinc borate, calcium stearate, sodium carboxymethyl cellulose, epoxidized soybean oil and lignin, stir at a constant speed for 10 minutes, take it out and knead in a kneader for 10 minutes, set Set t...

Embodiment 2

[0028] Example 2 Flame-retardant polypropylene insulating cable material, mainly prepared from the following raw materials (5kg each): 116 parts of polypropylene, 10 parts of white carbon black, 8 parts of sulfur, 9 parts of zinc borate, 10 parts of calcium stearate, carboxymethyl 12 parts of sodium cellulose, 11 parts of epoxidized soybean oil, 23 parts of aluminum hydroxide, 16 parts of diatomaceous earth, and 13 parts of lignin. The preparation method of above-mentioned flame-retardant polypropylene insulating cable material is:

[0029] (1) Mix aluminum hydroxide and diatomaceous earth, add water 0.6 times the mass of raw materials, pulverize for 50 minutes, pass the slurry through a 400-mesh sieve, dry and pulverize, and make powder;

[0030] (2) Mix white carbon black, sulfur, zinc borate, calcium stearate, sodium carboxymethyl cellulose, epoxidized soybean oil and lignin, stir at a constant speed for 30 minutes, take it out and knead in a kneader for 10 minutes, set ...

Embodiment 3

[0033] Example 3 Flame-retardant polypropylene insulating cable material, mainly prepared from the following raw materials (5kg each): 110 parts of polypropylene, 6 parts of white carbon black, 5 parts of sulfur, 5 parts of zinc borate, 7 parts of calcium stearate, carboxymethyl 8 parts of cellulose sodium, 6 parts of epoxidized soybean oil, 19 parts of aluminum hydroxide, 12 parts of diatomaceous earth, and 9 parts of lignin. The preparation method of above-mentioned flame-retardant polypropylene insulating cable material is:

[0034] (1) Mix aluminum hydroxide and diatomaceous earth, add water 0.4 times the mass of the raw materials, pulverize for 35 minutes, pass the slurry through a 250-mesh sieve, dry and pulverize, and make a powder;

[0035] (2) Mix white carbon black, sulfur, zinc borate, calcium stearate, sodium carboxymethyl cellulose, epoxidized soybean oil and lignin, stir at a constant speed for 15 minutes, take it out and knead in a kneader for 10 minutes, set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com