Injectable self-repairing hydrogel based on polysaccharides, preparation method and application of hydrogel to biological tissue engineering

A self-healing and hydrogel technology, applied in the application field of biological tissue engineering, can solve the problems of reduced service life of materials, achieve increased stability, simple and controllable synthesis method, and improve application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

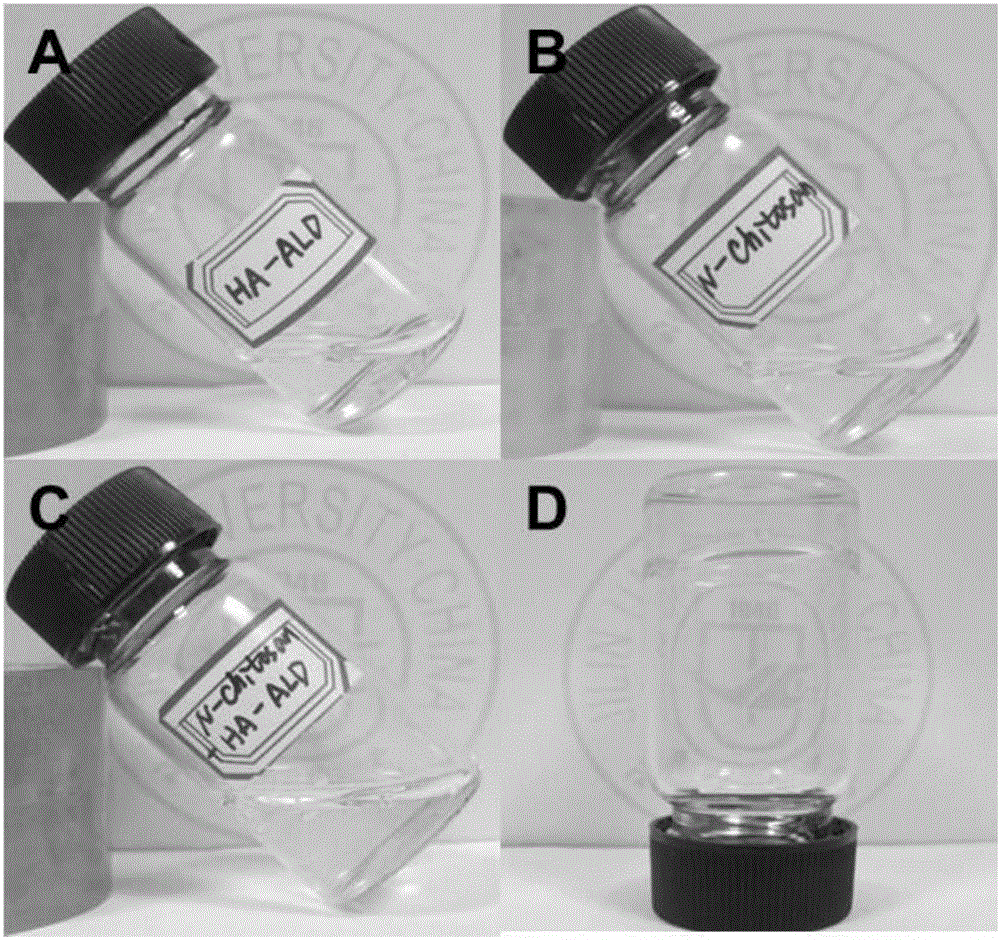

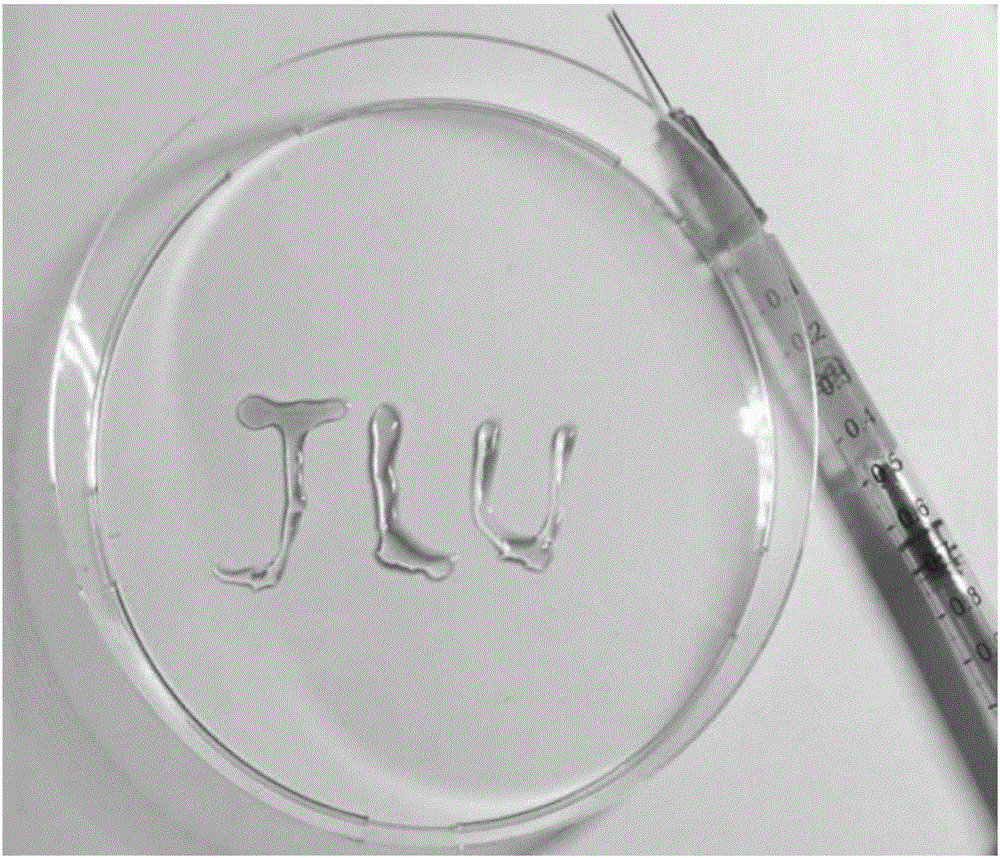

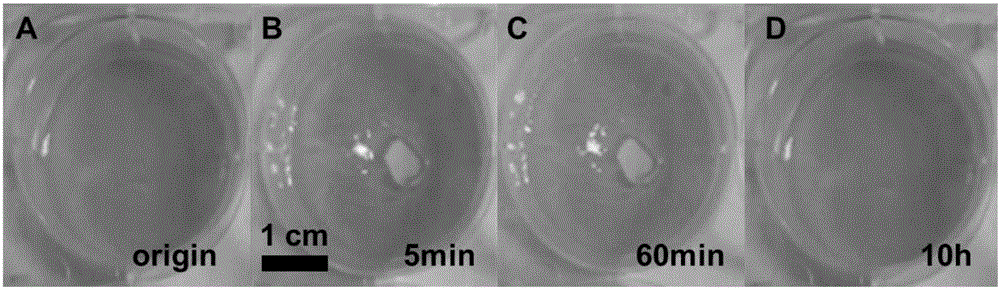

Embodiment 1

[0022] 1) 2.05g chitosan was stirred and dissolved in 100mL distilled water at room temperature. 1.5 mL of acrylic acid was slowly added dropwise, the temperature was raised to 50°C, and the reaction was carried out under magnetic stirring for 3 days to obtain a light yellow clear viscous liquid. The obtained polymer solution was cooled to room temperature, and 1M sodium hydroxide was added to adjust the pH of the system to 12. Dialyze with a 14,000 molecular weight dialysis bag for 3 days with constant water changes. The dialyzed polymer solution was used to remove most of the water with a rotary evaporator to obtain a clear liquid with a certain viscosity. Freeze-dry at -50°C for 3 days to obtain fluffy and porous N-carboxymethyl chitosan (N-carboxymethyl chitosan) solid powder A with a yield of about 75%.

[0023] 2) Take 1.00 g of sodium hyaluronate, stir and dissolve it in 100 mL of distilled water at room temperature, add sodium periodate (NaIO 4 ) 0.5528g, and stirre...

Embodiment 2

[0027] 1) 2.05g ethylene glycol chitosan was stirred and dissolved in 100mL distilled water at room temperature. 1.5 mL of acrylic acid was slowly added dropwise, the temperature was raised to 50°C, and the reaction was carried out under magnetic stirring for 3 days to obtain a light yellow clear viscous liquid. The obtained polymer solution was cooled to room temperature, and 1M sodium hydroxide was added to adjust the pH of the system to 12. Dialyze with a 8000 molecular weight dialysis bag for 3 days with constant water changes. The dialyzed polymer solution was used to remove most of the water with a rotary evaporator to obtain a clear liquid with a certain viscosity. Freeze-dry at -50°C for 3 days to obtain fluffy and porous N-carboxymethylethylene glycol chitosan solid powder A with a yield of about 75%.

[0028] 2) Take dextran sulfate 1.00g, stir and dissolve in 100mL distilled water at room temperature, add sodium periodate (NaIO 4 ) 0.30 g, and stirred for 4 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com