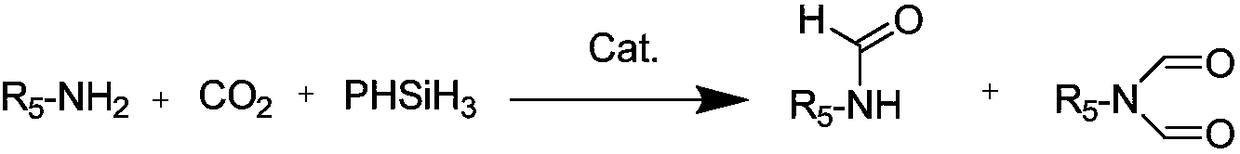

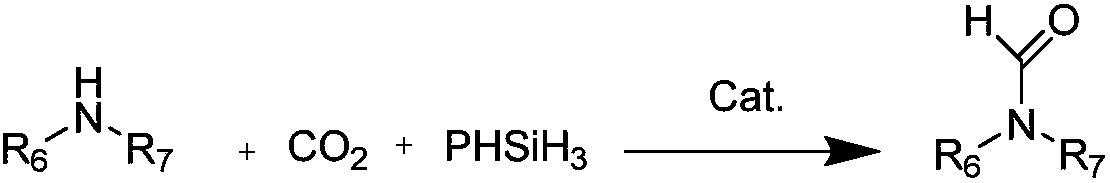

A kind of preparation method of n-formamide compounds

A technology for formamides and compounds, which is applied in the field of preparation of N-formamides, can solve the problems of difficult reuse of catalysts, need heavy metal catalysts, complex reaction systems and the like, and achieves low cost, high selectivity and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

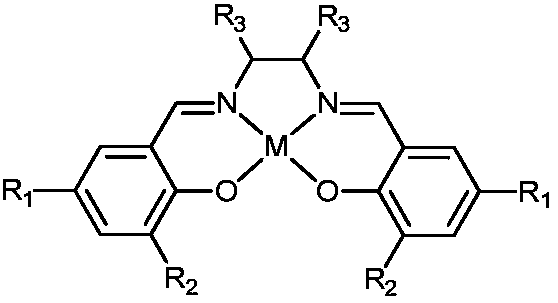

Embodiment 1

[0035] In the 10mL stainless steel autoclave, add the catalyst of 0.001mmol (M is Zn in the general formula (1), R 1 , R 2 , R 3 are all hydrogen groups) and 0.001mmol cocatalyst (R in general formula (2) 4 is n-butyl), 1mmo N-methylaniline and 1mmol phenylsilane are used as raw materials, the carbon dioxide pressure is adjusted to 0.5MPa, and the stirring reaction is carried out at a temperature of 25°C for 15h. After the reaction is completed, ether is added to centrifuge to recover the catalyst. The solvent was removed by rotary evaporation, and the product N-methylformanilide was obtained after vacuum drying with a yield of 95%.

Embodiment 2

[0037] In the 10mL stainless steel autoclave, add the catalyst of 0.001mmol (M is Al in the general formula (1), R 1 , R 2 , R 3 are all hydrogen groups) and 0.001mmol cocatalyst (R in general formula (2) 4 n-butyl), 1mmo N-methylaniline and 1mmol phenylsilane are used as raw materials, the carbon dioxide pressure is adjusted to 5MPa, and the stirring reaction is carried out at a temperature of 100°C for 3h. After the reaction, ethyl acetate is added to centrifuge to recover the catalyst. The solvent was removed from the clear liquid by rotary evaporation, and the product N-methylformanilide was obtained after vacuum drying with a yield of 99%.

Embodiment 3

[0039] In the 10mL stainless steel autoclave, add the catalyst of 0.001mmol (M is Co in the general formula (1), R 1 and R 3 are all hydrogen groups, R 2 is methyl) and 0.001mmol cocatalyst (R in general formula (2) 4 is n-butyl), 1mmol 2-methoxy-N-methylaniline and 1mmol diphenylsilane are used as raw materials, the pressure of carbon dioxide is adjusted to 1MPa, and the stirring reaction is carried out at a temperature of 60°C for 6h. After the reaction is completed, add two Methane chloride was centrifuged to recover the catalyst, the supernatant liquid was removed by rotary evaporation, and the product 2-methoxy-N-methylformanilide was obtained after vacuum drying with a yield of 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com