Disease-resistant organic fertilizer microorganism inoculant

A technology of fermentation bacteria and organic fertilizer, which is applied in the field of disease-resistant organic fertilizer fermentation bacteria, and can solve problems such as residues and threats to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

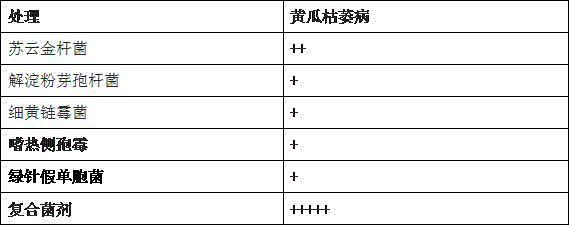

Examples

Embodiment 1

[0025] The ingredients are: 6 parts of Bacillus thuringiensis, 6 parts of Bacillus amyloliquefaciens, 8 parts of Streptomyces luteus, 4 parts of Sporosporium thermophila, 4 parts of Pseudomonas chlorous, 30 parts of modified zeolite powder, potassium fulvic acid 4 parts of powder, 3 parts of sodium alginate, 0.6 parts of water retaining agent, 2 parts of polyaspartic acid, 5 parts of corn starch, 2 parts of tea saponin, 1 part of compound enzyme preparation, 3 parts of sodium lignosulfonate, citric acid 0.7 parts, 0.8 parts of sodium bisulfite;

[0026] The water retaining agent is an equal amount of polyacrylamide and sodium polyacrylate;

[0027] The compound enzyme preparation is cellulase, amylase and ligninase, and the weight ratio of the three is 3:1:1;

[0028]The preparation process of the modified zeolite powder includes: adding the natural zeolite powder into the concentrated nitric acid solution, stirring for 5 hours, filtering, and drying; and then calcining the z...

Embodiment 2

[0035] The ingredients are: 5 parts of Bacillus thuringiensis, 5 parts of Bacillus amyloliquefaciens, 5 parts of Streptomyces luteus, 3 parts of Sporosporium thermophila, 3 parts of Pseudomonas chloropinus, 20 parts of modified zeolite powder, potassium fulvic acid 1.5 parts of powder, 0.5 parts of sodium alginate, 0.5 parts of water retaining agent, 1 part of polyaspartic acid, 3 parts of corn starch, 0.5 parts of tea saponin, 0.5 parts of compound enzyme preparation, 1 part of sodium lignosulfonate, citric acid 0.5 part, 0.5 part of sodium bisulfite;

[0036] The water retaining agent is an equal amount of polyacrylamide and sodium polyacrylate;

[0037] The compound enzyme preparation is cellulase, amylase and ligninase, and the weight ratio of the three is 3:1:1;

[0038] The preparation process of the modified zeolite powder includes: adding the natural zeolite powder into the concentrated nitric acid solution and stirring for 3 hours, filtering, and drying; then, the ze...

Embodiment 3

[0045] The ingredients are: 10 parts of Bacillus thuringiensis, 10 parts of Bacillus amyloliquefaciens, 10 parts of Streptomyces luteus, 5 parts of Sporosporium thermophila, 5 parts of Pseudomonas chloropinus, 40 parts of modified zeolite powder, potassium fulvic acid 5 parts of powder, 5 parts of sodium alginate, 1 part of water retaining agent, 3 parts of polyaspartic acid, 6 parts of corn starch, 3 parts of tea saponin, 2 parts of compound enzyme preparation, 5 parts of sodium lignosulfonate, citric acid 1 part, 1 part of sodium bisulfite;

[0046] The water retaining agent is an equal amount of polyacrylamide and sodium polyacrylate;

[0047] The compound enzyme preparation is cellulase, amylase and ligninase, and the weight ratio of the three is 3:1:1;

[0048] The preparation process of the modified zeolite powder includes: adding the natural zeolite powder into the concentrated nitric acid solution and stirring for 3 hours, filtering, and drying; then, the zeolite is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com