Processing method of hole decorative plate based on gray scale and processing system using it

A processing method and decorative board technology, applied in decorative arts, decorative structures, etc., can solve the problems of long production preparation time, no automatic function, blurred image features, etc., to reduce labor consumption, improve imaging quality, and avoid feature loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

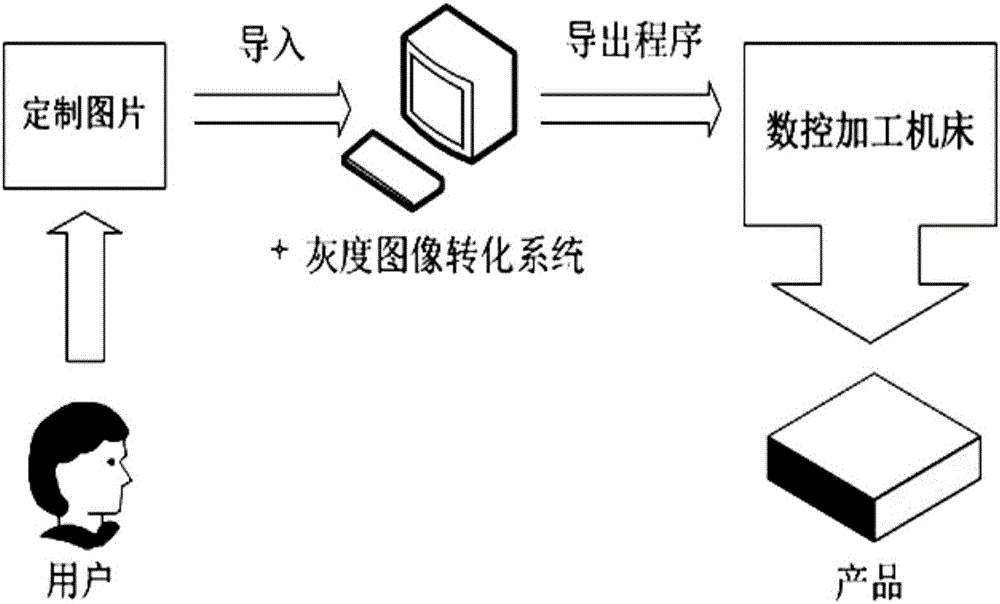

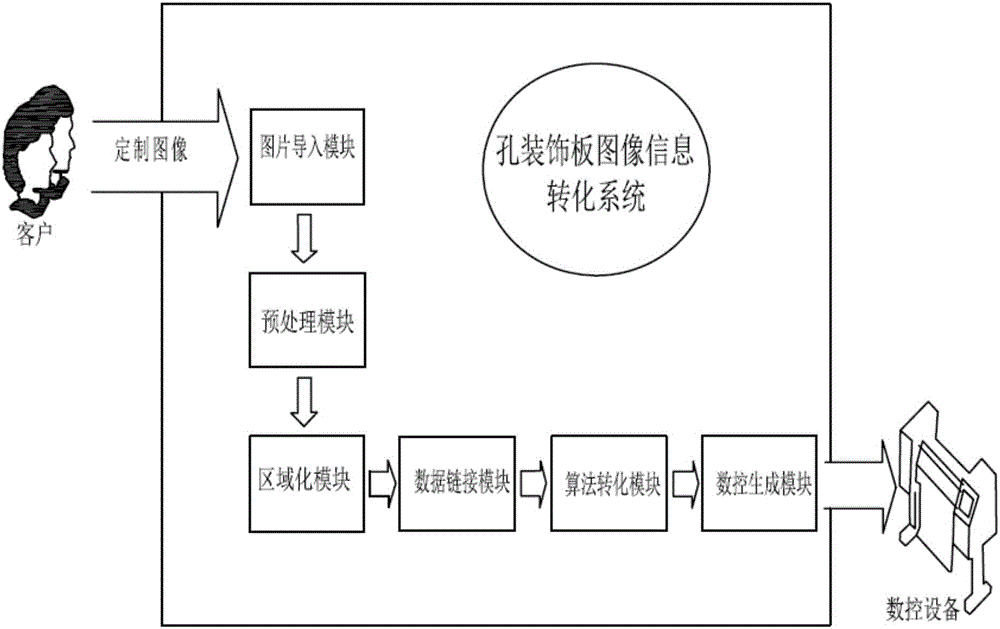

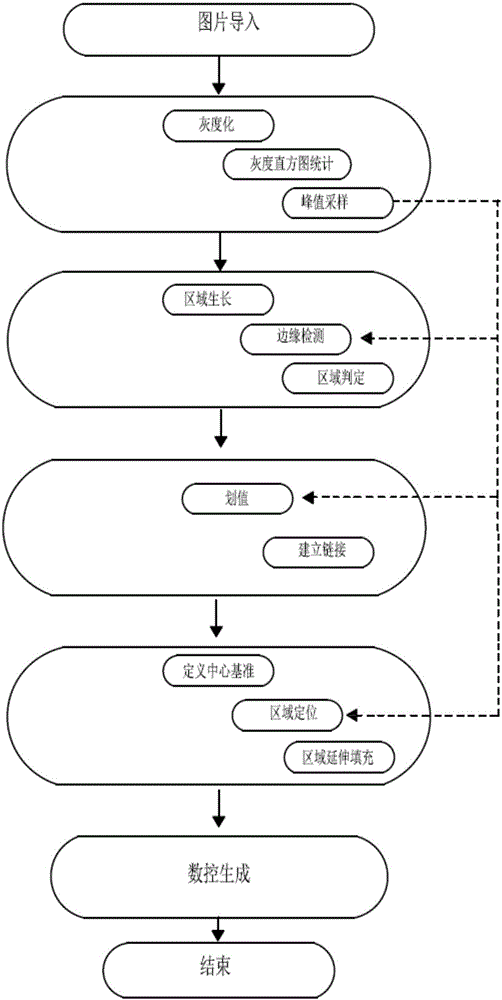

[0046] Such as Figure 1-3 As shown, the grayscale-based hole decorative plate processing method is applied to a numerical control processing machine tool, and the processing method includes the following steps:

[0047] 1. Acquiring customized images: In this system, obtaining the corresponding images as the target is the basis of the entire system. When the customer requests to customize the product with an image, the customized specific image is obtained. Use the port provided by the system to import the image into the system. However, the system processing flow can only be compatible with a specific file format, so in this step, the image will first be converted into a specific image format file compatible with the system.

[0048] 2. Grayscale preprocessing: After the image is acquired, it can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com