Preparation method for rhenium-iridium combustion chamber

A combustion chamber, rhenium-iridium technology, which is applied in the field of preparation of rhenium-iridium combustion chambers to achieve the effects of ensuring working life, prolonging flight life and increasing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

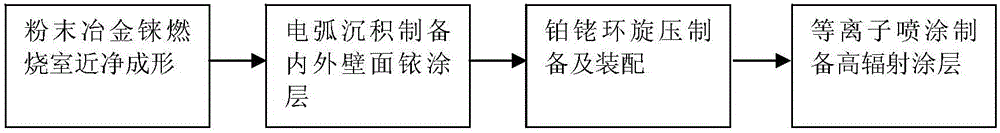

[0040] Such as figure 1 Shown is the flow chart of the preparation method of the rhenium-iridium combustion chamber of the present invention, and the preparation method of the rhenium-iridium combustion chamber of the present invention specifically includes the following steps:

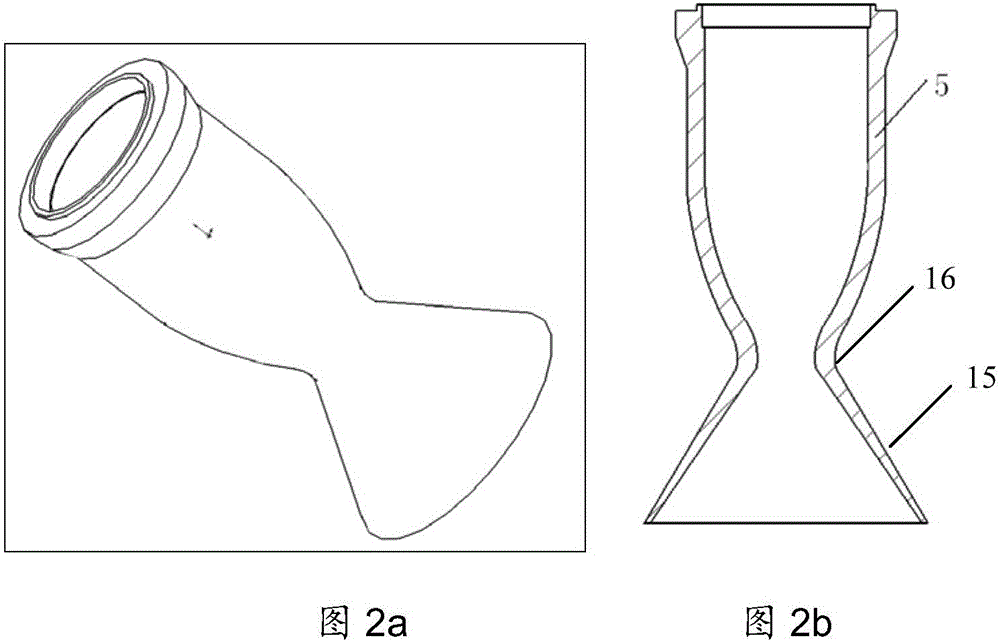

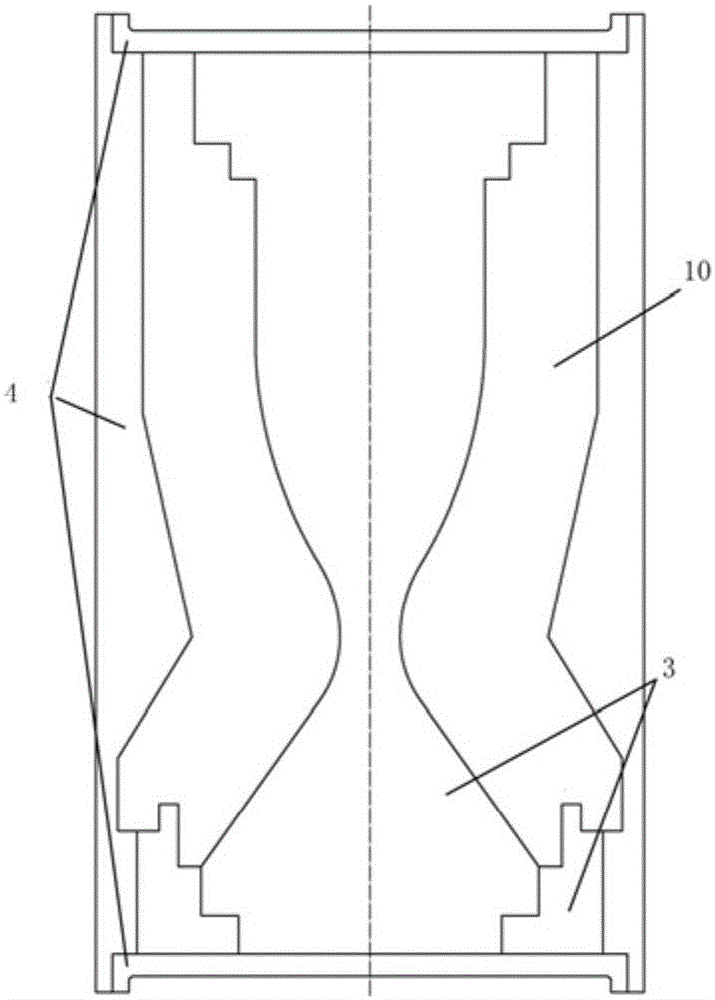

[0041] Step (1), the rhenium combustion chamber substrate 5 is prepared by powder metallurgy forming process, and in order to realize the subsequent welding process, niobium alloy rings need to be formed at the inlet ends of both ends of the rhenium combustion chamber to realize integral molding of rhenium and niobium, and strengthen through subsequent heat treatment Rhenium and niobium diffuse to improve the interface bonding strength. The material of the sheath 4 used in the powder metallurgy process is low carbon steel. The core mold 3 used in the powder metallurgy process is made of niobium-tungsten alloy, and a bevel locking structure is designed to enhance the connection with rhenium.

[0042]...

Embodiment 1

[0054] (1), using powder metallurgy technology net shape rhenium combustion chamber substrate, using figure 2 For the mold shown, the forming process conditions are: temperature 1300°C, pressure 150MPa, holding time 5h. The subsequent heat treatment process is characterized by a vacuum environment ≤ 1×10 -3 Pa, temperature 1550°C, holding time 3h.

[0055] The size of the combustion chamber is machined in place by machining. The total length of the combustion chamber is 130mm, the maximum outer diameter is Ф70mm, the straight section of the inner diameter is Ф45mm, and the throat diameter is Ф20mm.

[0056] (2), use the mixed acid of the sulfuric acid of 15% (mass concentration), 20% (mass concentration) hydrochloric acid to clean, clean with distilled water then, dry;

[0057] (3) Using the arc deposition process, the iridium target material used for preparing the iridium coating on the inner surface of the rhenium combustion chamber substrate 5 is in the shape of a trunca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com