Improved engine cylinder block and manufacturing technique thereof

A technology of engine cylinder block and cylinder block, which is applied in the direction of engine components, machines/engines, cylinders, etc., can solve problems such as difficult to meet the requirements of automobile engines and poor sealing performance of piston rings, and achieve simple manufacturing process, prolong service life, and improve The effect of manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

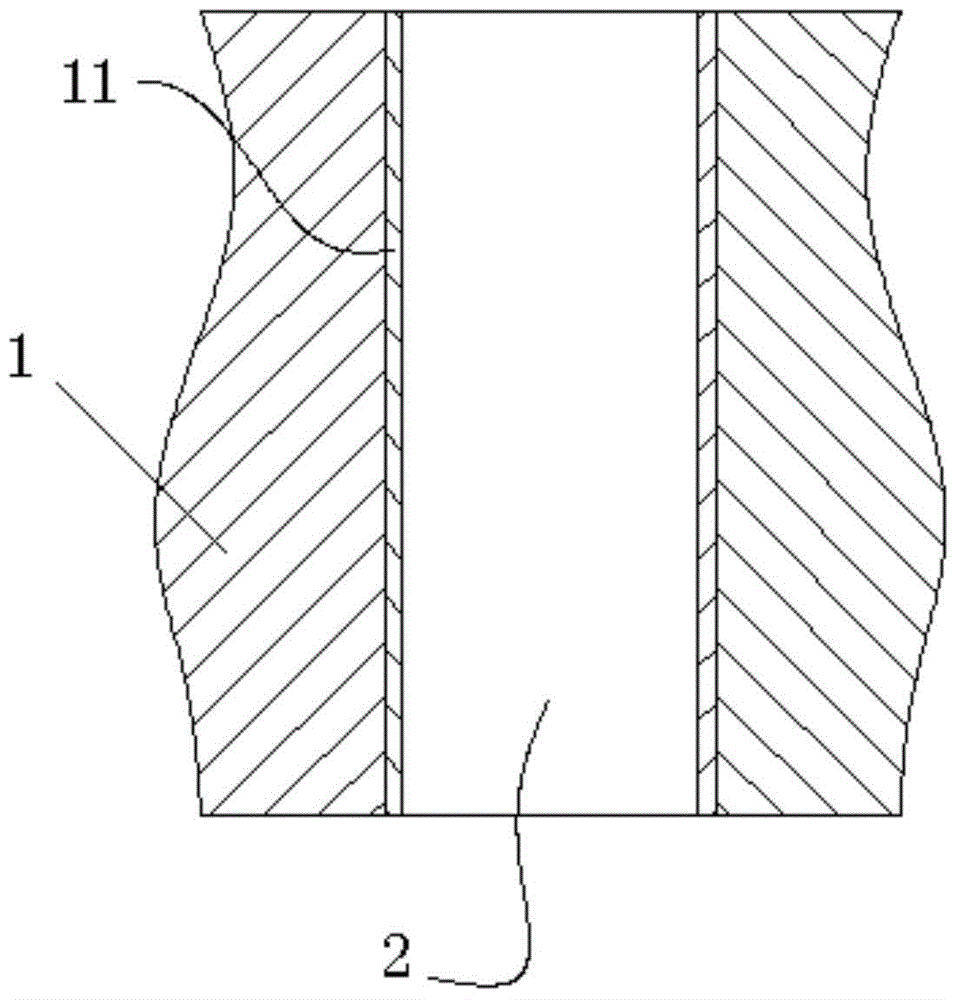

[0033] Such as figure 1 As shown, an improved engine block of the present invention includes a block body 1, a cylinder body 1 is provided with a cylinder hole 2, and the inner wall of the cylinder hole 2 is provided with a wear-resistant layer 11; the wear-resistant layer 11 Made of cast iron coating. The thickness of the cast iron coating is 1mm-2mm, preferably 1.5mm. The number of the cylinder holes 2 is set according to actual needs, such as four. The cast iron coating provided in the present invention improves the wear resistance of the inner wall of the cylinder bore 2 .

[0034] In specific manufacturing, the existing mature plasma spraying technology is used to spray a 1mm-2mm cast iron coating on the inner surface of the cylinder bore 2 of the roughly machined engine block to obtain an engine block compounded with a uniform thickness of cast iron coating . It is especially suitable for the production and manufacture of cast aluminum engines, such as spraying cast ...

Embodiment 2

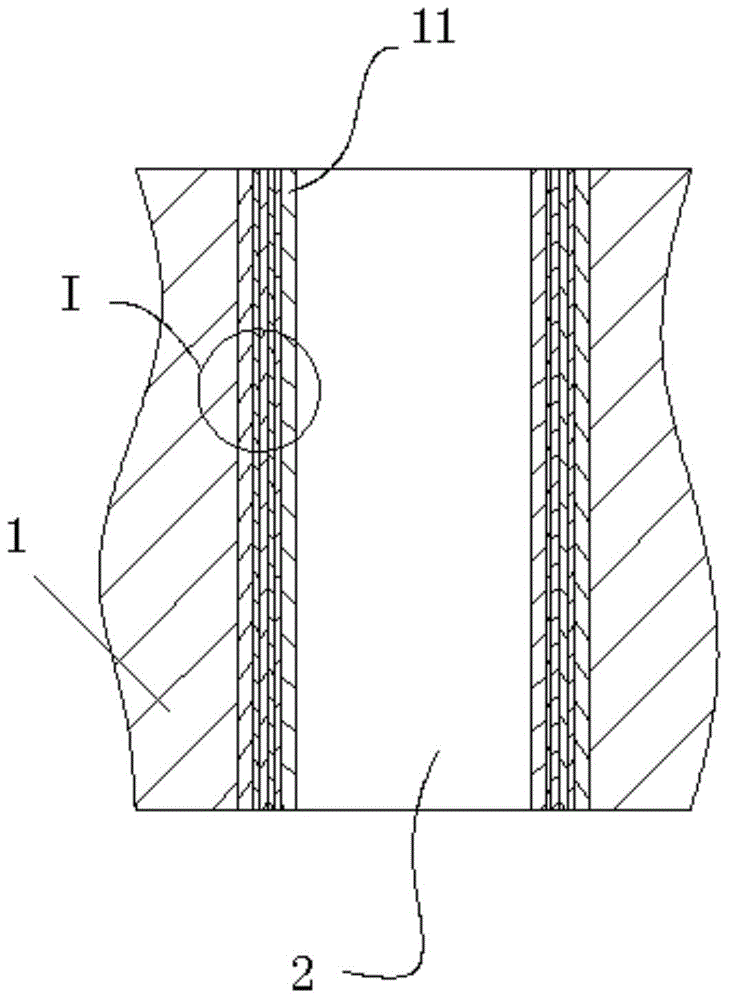

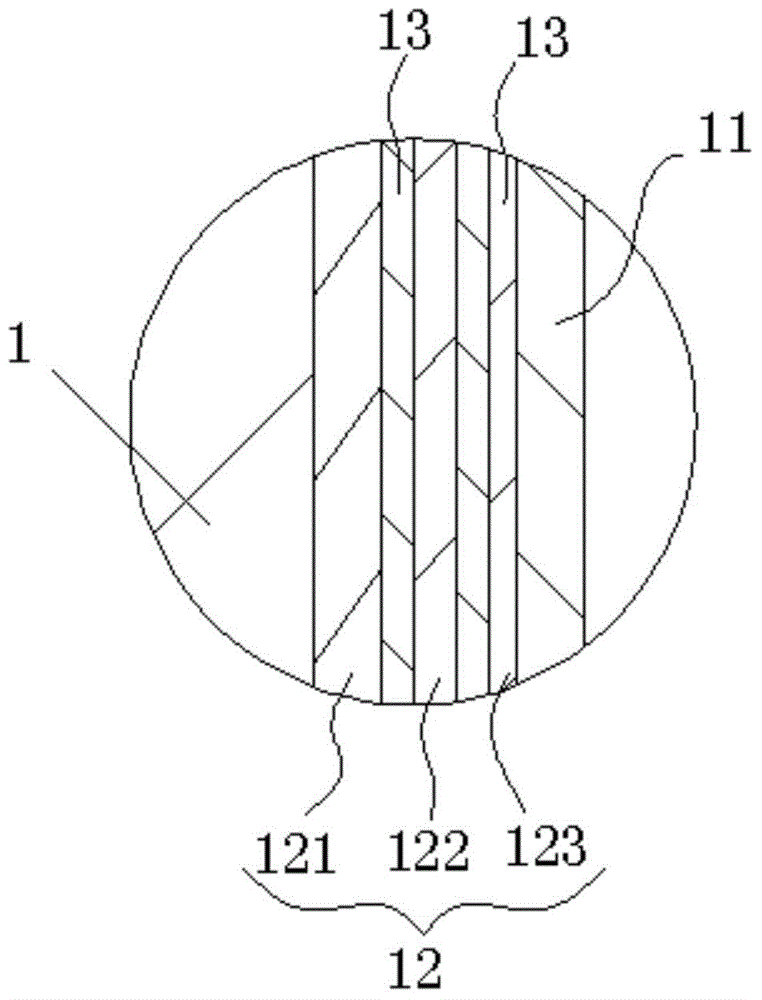

[0045] Such as figure 2 , 3 As shown, the improved engine block of the present invention also provides a second embodiment, which is different from Embodiment 1 in that: a nickel coating 12 is provided between the inner wall of the cylinder bore 2 and the wear-resistant layer 11, and the nickel coating The layer 12 includes an inner nickel coating 121 , a middle nickel coating 122 and an outer nickel coating 123 sequentially arranged along the cylinder body 1 from inside to outside.

[0046] A copper coating 13 is provided between the inner nickel coating 121 and the middle nickel coating 122 , and a copper coating 13 is provided between the middle nickel coating 122 and the outer nickel coating 123 .

[0047] Further, the thickness of the inner nickel coating 121 is 0.4mm-0.5mm, the thickness of the middle nickel coating 122 is 0.2mm-0.3mm, and the thickness of the outer nickel coating 123 is 0.15mm-0.2mm , the thickness of the copper coating 13 is 0.005mm-0.1mm.

[0048]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com