Corn stalk pre-processing method

A corn stalk and pretreatment technology, applied in the field of chemical engineering, can solve the problems of high cost and large amount of NMMO, and achieve the effect of reducing the amount of use, efficient enzymatic hydrolysis, and reducing the cost of pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

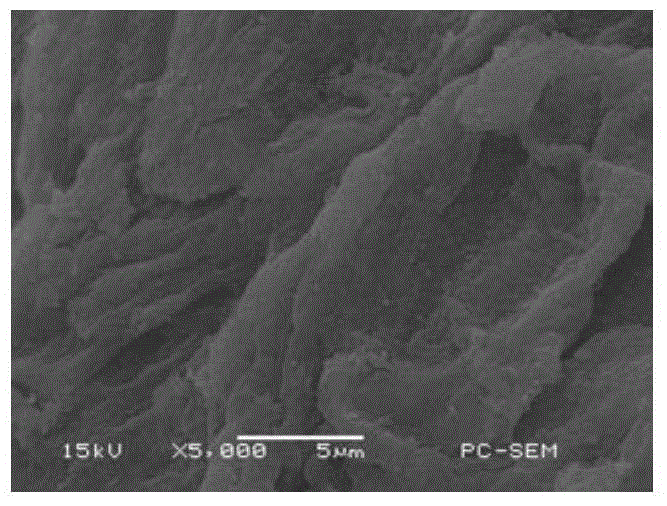

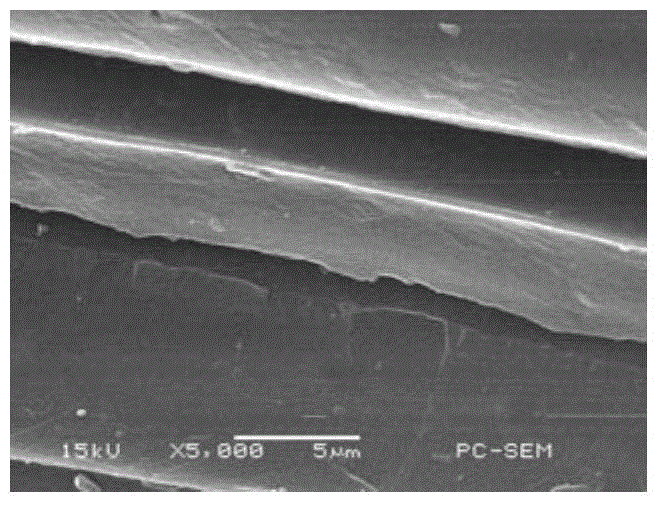

[0039] 70% (w / w) NMMO, 15% (w / w) ethylene glycol and 15% (w / w) water mixture 10mL, add 0.1g dry corn stalks, and stir in an oil bath at 100°C for 2h after pretreatment, Add deionized water to regenerate. Electron microscope analysis and comparison of pretreated corn stalks and untreated corn stalks, as shown in Figure 1a with Figure 1b It was shown that the surface of pretreated corn stover was rough, and the dense advanced structure was destroyed and became loose, which fully exposed the cellulose, increased the accessibility of cellulase, and thus increased the saccharification rate.

Embodiment 2

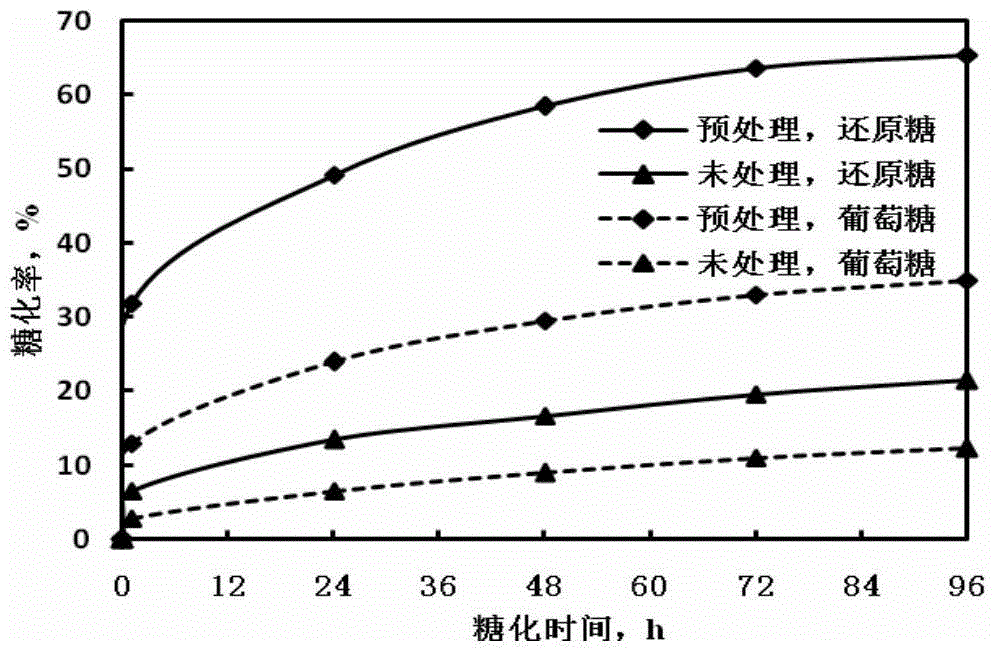

[0041]75% (w / w) NMMO, 10% (w / w) ethylene glycol and 15% (w / w) water mixture 10mL, add 0.1g dry corn stover, after pretreatment at 130℃ for 0.5h, add Deionized water yields regenerated cellulosic material. After the regenerated cellulose material was washed 3 times with deionized water, a pH=4.8 acetic acid-sodium acetate buffer was added to form a mixed system, so that the final mass concentration of corn stalks was 10 g / L, and then cellulase (20 FPU / g corn stalks ) to carry out enzymolysis, shake the reaction for 96h on a constant temperature shaker at 50°C and 180rpm, the yield of reducing sugar is 65.4%, and the yield of glucose is 35.0% (such as figure 2 , image 3 ).

Embodiment 3

[0043] 80% (w / w) NMMO, 5% (w / w) ethylene glycol, 15% (w / w) water mixture 10mL, add 0.5g dry corn stalks, pretreat corn stalks at 130℃ for 1h , adding deionized water to obtain a regenerated cellulose material. After the regenerated cellulose material was washed 3 times with deionized water, a pH=4.8 acetic acid-sodium acetate buffer was added to form a mixed system, so that the final mass concentration of corn stalks was 10 g / L, and then cellulase (20 FPU / g corn stalks ) for enzymolysis, shaking and reacting on a constant temperature shaker at 50° C. and 180 rpm for 96 hours, the yield of reducing sugar was 64.7%, and the yield of glucose was 34.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com