Processing method of spliced adhesive tape

A processing method and tape technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of raw material waste, labor consumption, low efficiency, etc., and achieve the effect of improving efficiency, saving costs, and reducing process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

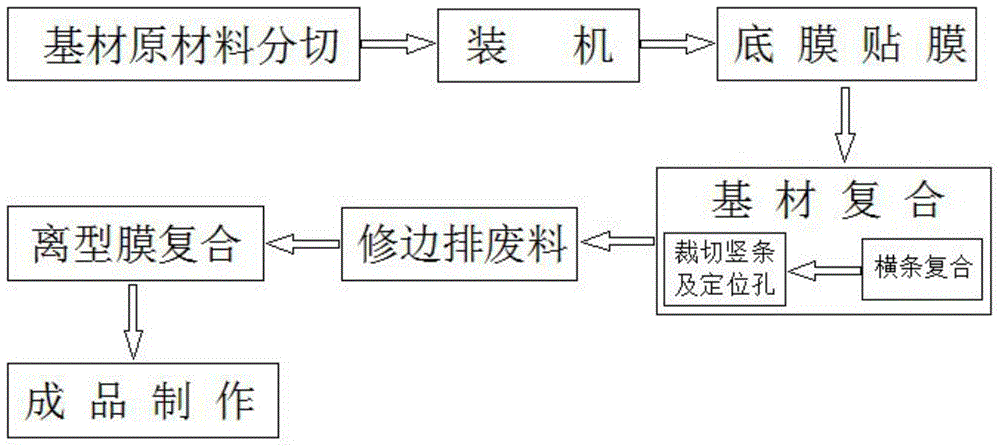

[0025] Such as figure 1 Shown, a kind of processing method of splicing adhesive tape comprises base film, transfer film, base material, release film, and described processing method comprises following processing steps:

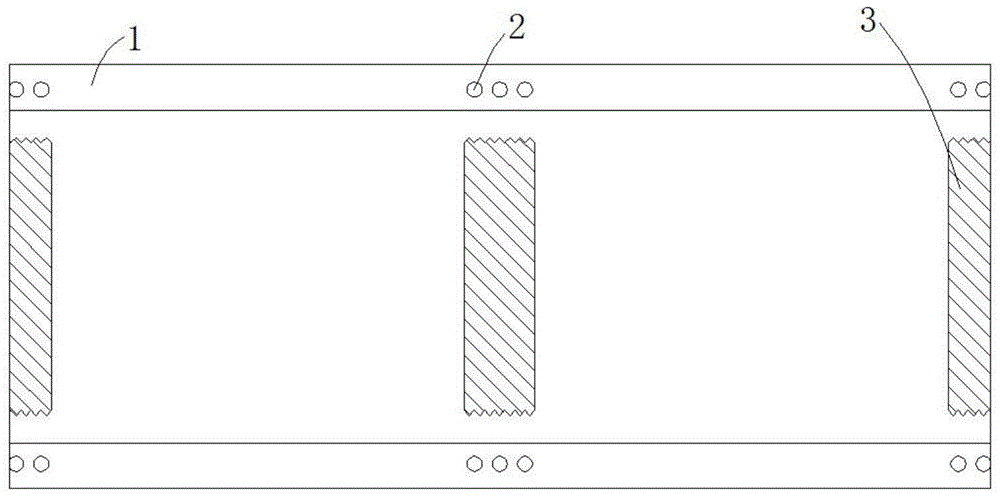

[0026] A. Slitting of substrate raw materials, cutting the substrate raw materials into several small rolls of substrates with regularly arranged zigzag or concave-convex edges;

[0027] B. Install the machine, respectively install the bottom film, transfer film, small roll base material, and release film on the machine in a certain order;

[0028] C. The base film is pasted, and the transfer film is compounded on the upper surface of the base film;

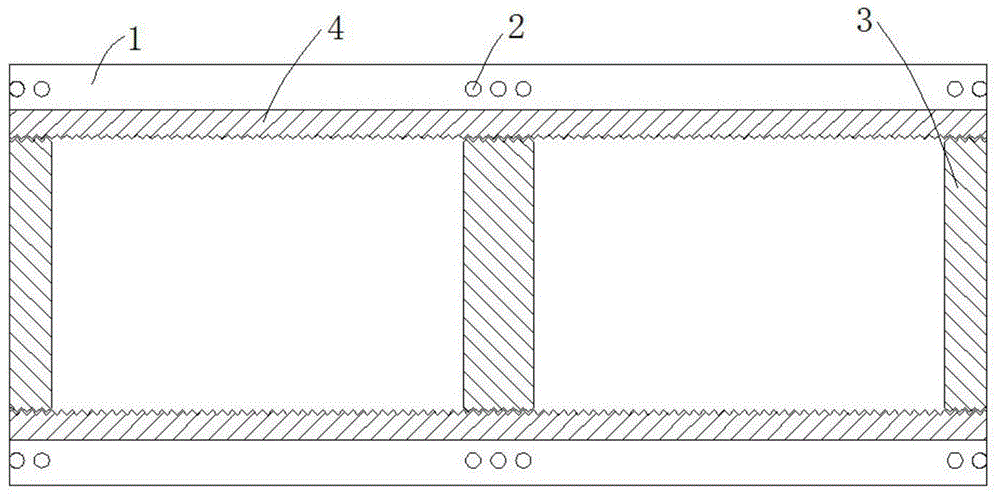

[0029] D. Substrate compounding, compounding the substrate on the upper surface of the transfer film;

[0030] E. Trimming and waste removal: use the mold to position the semi-finished product made in step C, punch out the excess base material on the lateral inner side, and remove the waste material and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com