Water-based nanometer color paste, water-based thermal sublimation jet ink containing same, and method for preparing water-based thermal sublimation jet ink

A technology of nano-color paste and inkjet ink, which is applied in the direction of ink, pigment paste, household appliances, etc. It can solve the problems of poor storage stability, weak binding force of dispersant, low dyestuff, etc., and achieve slow volatilization speed and high suspension stability high stability and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 yellow water-based nano color paste I

[0029] The formula of yellow water-based nano color paste I is shown in the following table:

[0030] Dye sublimation dye (54 yellow)

25 copies

Coating treatment agent (acrylic polymer containing pyridine segment)

5 copies

Defoamer (Evonik Degussa Tego Foamex 810)

0.4 parts

water

70 copies

Dispersant (Byk Chemicals Disperbyk-190)

25 copies

pH regulator (Dow Chemical AMP-95)

0.6 parts

Grinding aid (diethylene glycol of Sinopharm Reagent Co., Ltd.)

8 servings

[0031] Preparation:

[0032] (1) Add coating treatment agent and defoamer to water first, stir evenly, add sublimation dye under medium speed stirring, after mixing evenly, disperse in colloid mill for 8 hours;

[0033] (2) Under stirring conditions, add dispersant, pH regulator and grinding aid to the slurry obtained in step (1), after mixing evenly, grind in a sand mill for 1...

Embodiment 2

[0035] Embodiment 2 yellow water-based thermal sublimation inkjet ink I

[0036] The formula of yellow water-based sublimation inkjet ink I is shown in the table below:

[0037] Dye color paste

[0038] After the above components are mixed evenly, filter under reduced pressure with a nanofiltration membrane of 1 micron, and the filtered ink is the yellow water-based sublimation inkjet ink I. The obtained ink has an average particle diameter of about 71 nanometers and a D98 particle diameter of 350 nanometers, and after being placed in an oven at 60° C. for one week, the particle diameter does not change. After the ink is stored in the ink cartridge for half a year, there will be no color difference when printing.

Embodiment 3

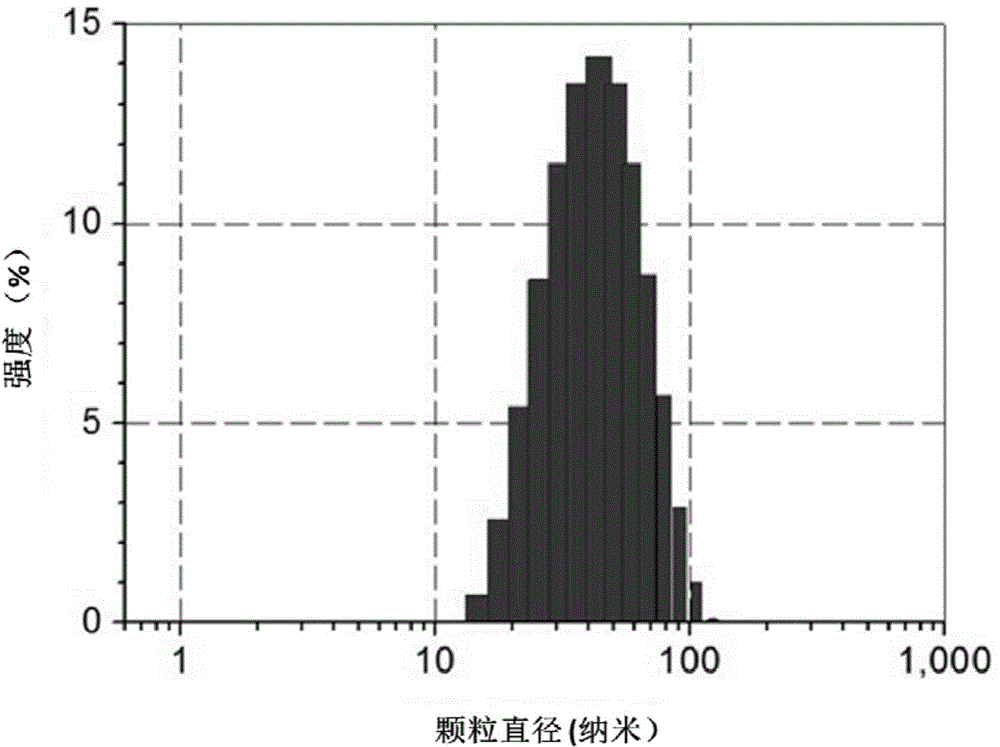

[0039] Embodiment 3 red water-based nano color paste

[0040] The formula of red water-based nano color paste is shown in the table below:

[0041] Dye sublimation dye (60 red)

25 copies

Coating treatment agent (polyester polymer containing amino segment)

8 servings

Defoamer (BYK-019)

0.4 parts

water

70 copies

Dispersant (BASF EFKA-4585)

30 copies

pH regulator (Dow Chemical AMP-95)

0.6 parts

Grinding aid (triethylene glycol of Sinopharm Reagent Co., Ltd.)

10 copies

[0042] Preparation:

[0043] (1) Add coating treatment agent and defoamer to water first, stir evenly, add sublimation dye under medium speed stirring, after mixing evenly, disperse in colloid mill for 8 hours;

[0044] (2) Under stirring conditions, add dispersant, pH regulator and grinding aid to the slurry obtained in step (1), after mixing evenly, grind in a sand mill for 12 hours to obtain red water-based nano-color paste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com