Electrode material surface coating method and application thereof

An electrode material and surface coating technology, which is applied in the fields of lithium ion batteries, electrode material preparation and lithium ion batteries, can solve the problems of limited application range, inability to form a coating layer, and reduction of the gram capacity of multi-materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

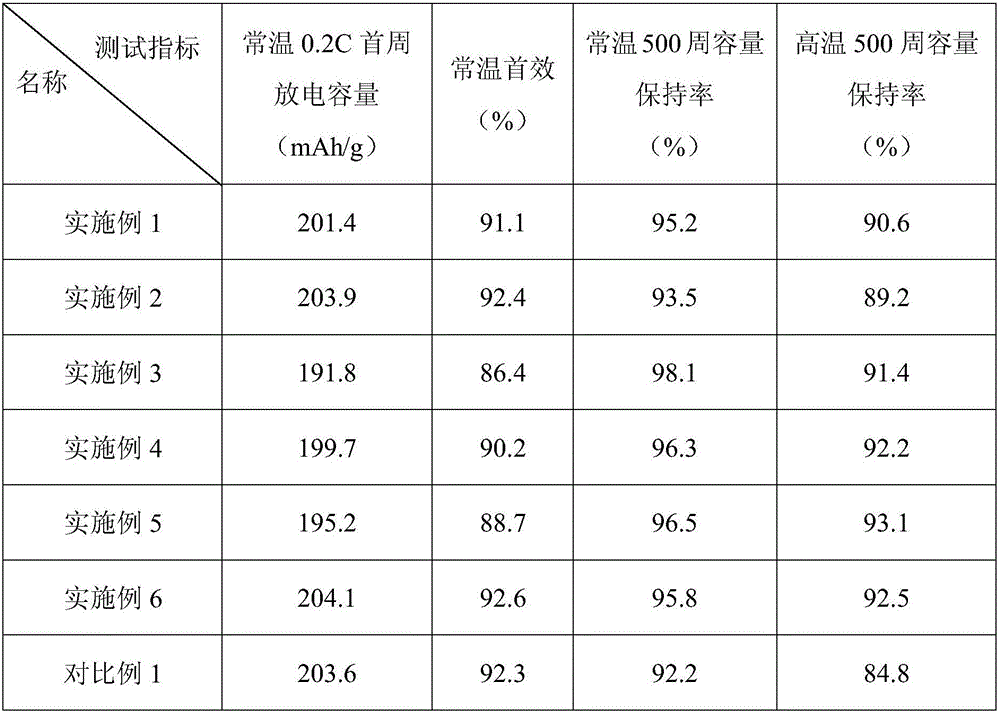

Examples

Embodiment 1

[0061] Combine water and multi-element cathode material LiNi 0.8 Co 0.15 Al 0.05 O 2 Mix at a mass ratio of 10:1, stir for 5 hours, centrifuge and dry to obtain LiNi after removing residual alkali 0.8 Co 0.15 Al 0.05 O 2 .

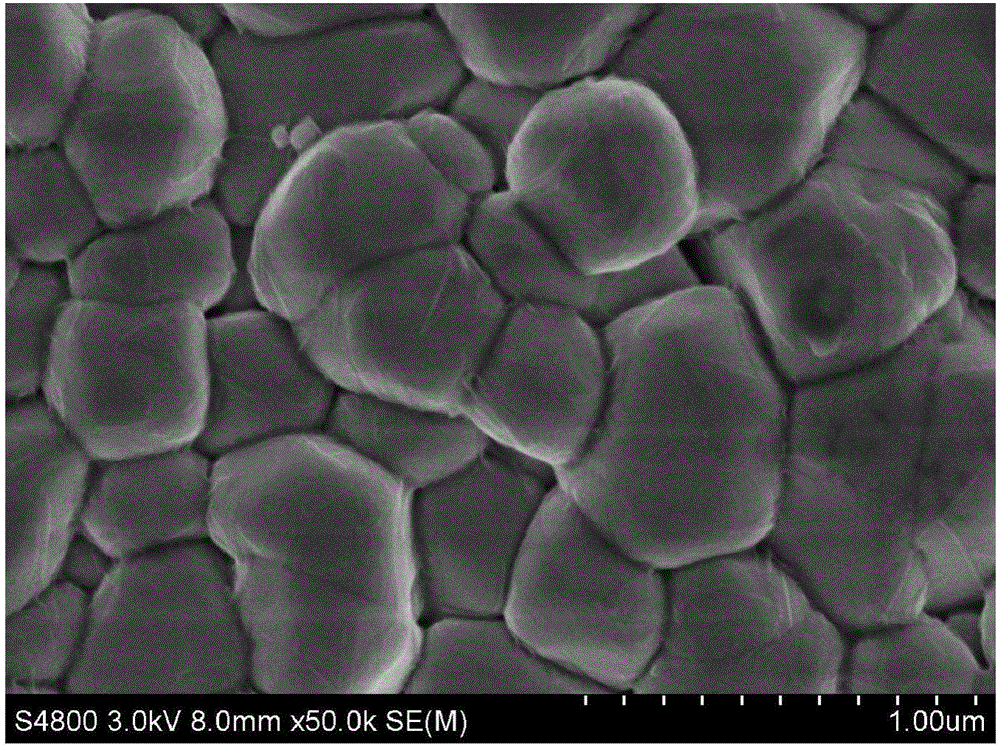

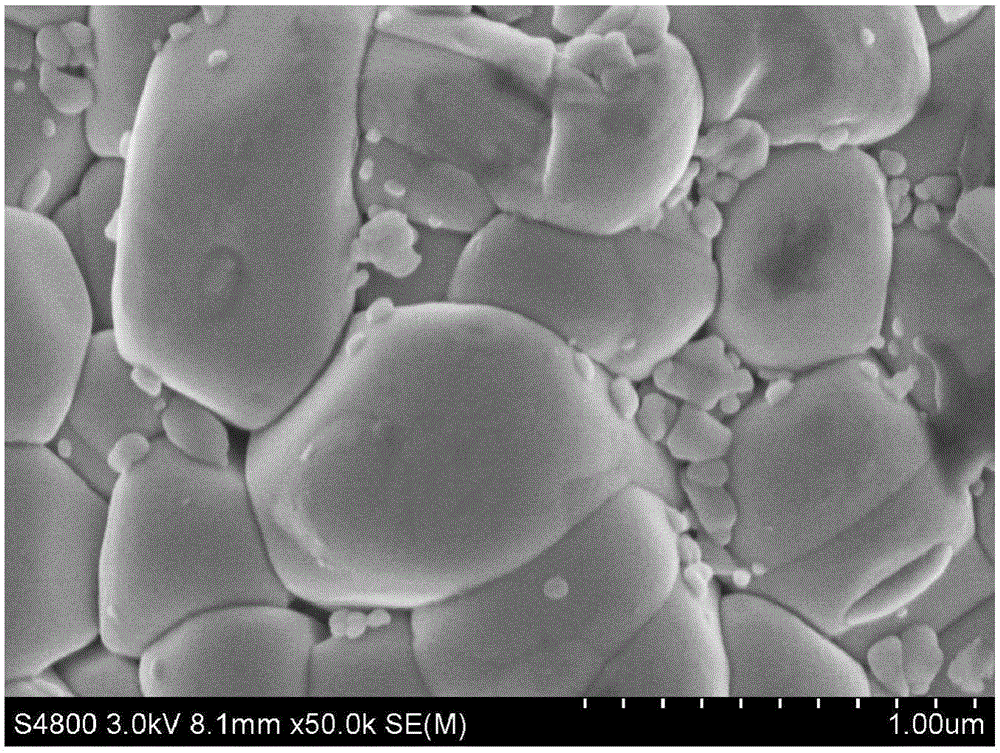

[0062] Take 10g LiOH·H 2 O and 1000g of LiNi after removing residual alkali 0.8 Co 0.15 Al 0.05 O 2 Pour into the mixer, mix at 1000r / min for 10min, weigh 5g TiO 2 Pour into the mixer and continue mixing at 1000r / min for 10 minutes; after mixing, take out the mixture and sinter at 500°C, during which oxygen is introduced at 6L / h, and after sintering for 3 hours, the temperature is increased to 800°C, and sintering is continued After 5h, it was cooled to room temperature, crushed and passed through a 200-mesh sieve to obtain a multi-element cathode material coated with Li-Ti-O oxide layer. The scanning electron microscope image of the multi-element cathode material coated with Li-Ti-O oxide layer is as follows figure 1 As shown, the Li-Ti-O oxide coating layer ...

Embodiment 2

[0064] Combine water and multi-element cathode material LiNi 0.85 Co 0.10 Al 0.05 O 2 Mix according to the mass ratio of 0.5:1, stir for 10h, centrifuge, and dry to obtain LiNi after removing residual alkali 0.85 Co 0.10 Al 0.05 O 2 .

[0065] Take 20g LiOH·H 2 O and 1000g of LiNi after removing residual alkali 0.85 Co 0.10 Al 0.05 O 2 Pour into the mixer, mix at 1000r / min for 5h, weigh 2g TiO 2 Pour into the mixer and continue mixing at 800r / min for 1h; after mixing, take out the mixture and sinter at 400℃, during which oxygen is injected at 20L / h. After sintering for 20h, increase the temperature to 1000℃ and continue sintering After 6 hours, it was cooled to room temperature, crushed and passed through a 200-mesh sieve to obtain a multi-element cathode material coated with Li-Ti-O oxide layer. The scanning electron microscope image of the multi-element cathode material coated with Li-Ti-O oxide is as follows figure 1 As shown, the Li-Ti-O oxide coating layer on the surface is o...

Embodiment 3

[0067] Combine water and multi-element cathode material LiNi 0.85 Co 0.10 Al 0.05 O 2 Mix at a mass ratio of 6:1, stir for 8h, centrifuge, and dry to obtain LiNi after removing residual alkali 0.85 Co 0.10 Al 0.05 O 2 .

[0068] Take 5g LiOH·H 2 O and 1000g of LiNi after removing residual alkali 0.85 Co 0.10 Al 0.05 O 2 Pour into the mixer, mix at 2000r / min for 15min, weigh 40g TiO 2 Pour into the mixer and continue mixing at 1500r / min for 10 minutes; after mixing, take out the mixture and sinter at 600°C. During the sintering process, 5L / h oxygen is introduced. After sintering for 2 hours, the temperature is increased to 700°C, and sintering is continued. After 30 hours, it was cooled to room temperature, crushed and passed through a 200-mesh sieve to obtain a multi-element cathode material coated with Li-Ti-O oxide layer. The scanning electron microscope image of the multi-element cathode material coated with Li-Ti-O oxide showed that the surface The Li-Ti-O oxide coating layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com