Drilling dynamics simulation test system

A technology of simulation testing and dynamics, applied in the field of drilling engineering and geotechnical mechanics, can solve the problems of inability to implement rotation, rotation-shock pulse loading experiment rod application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

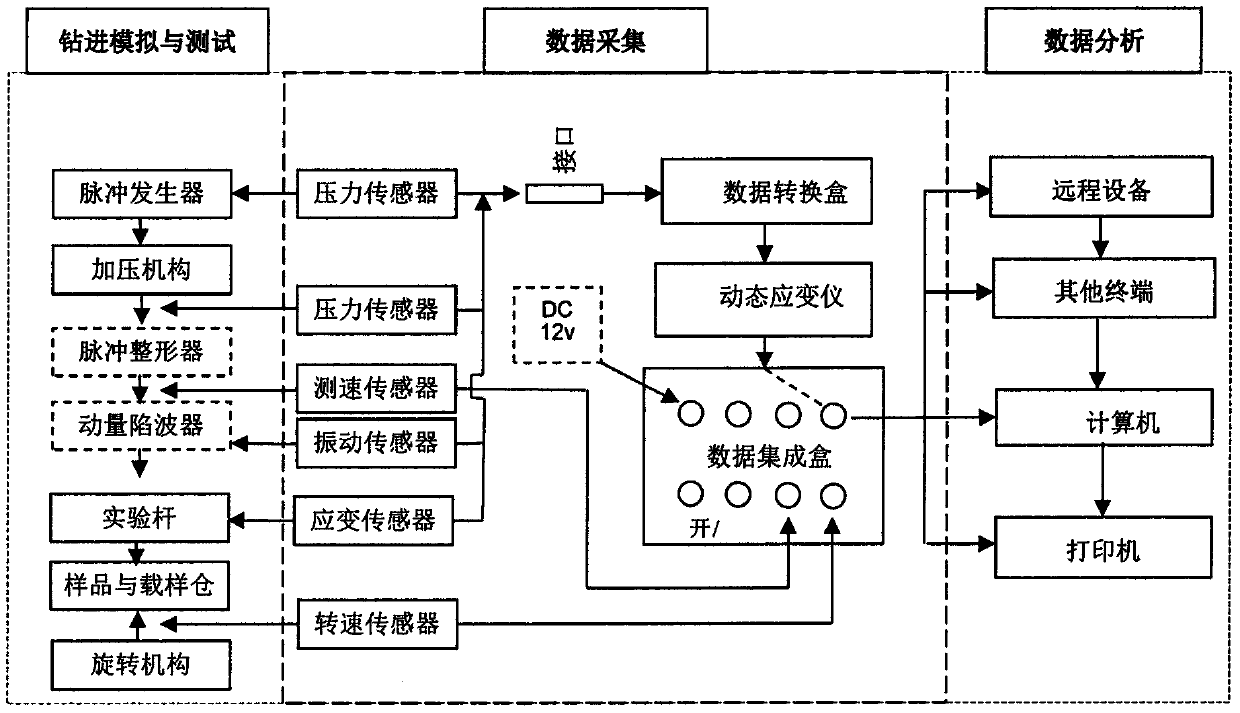

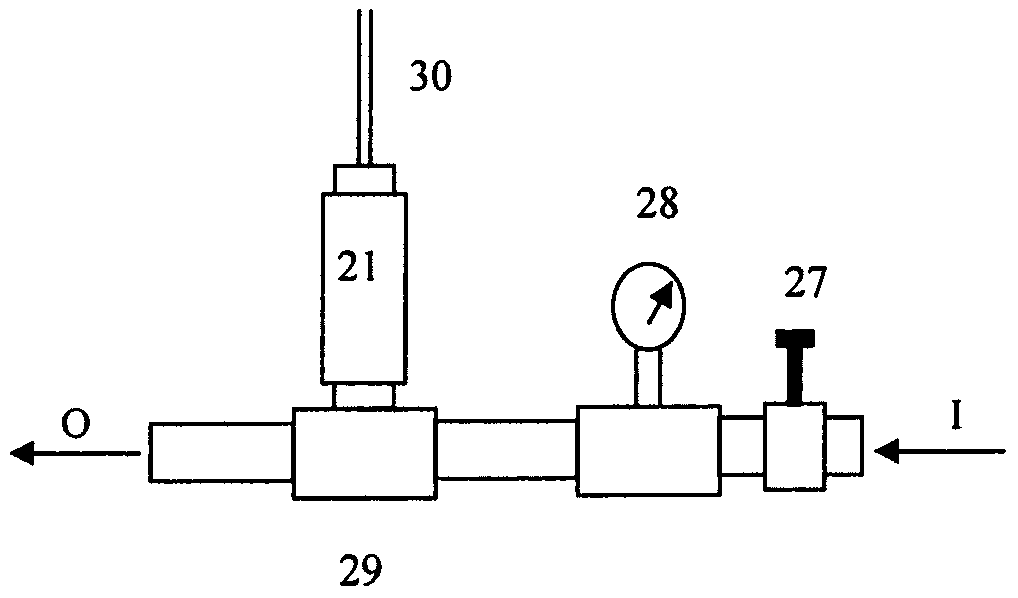

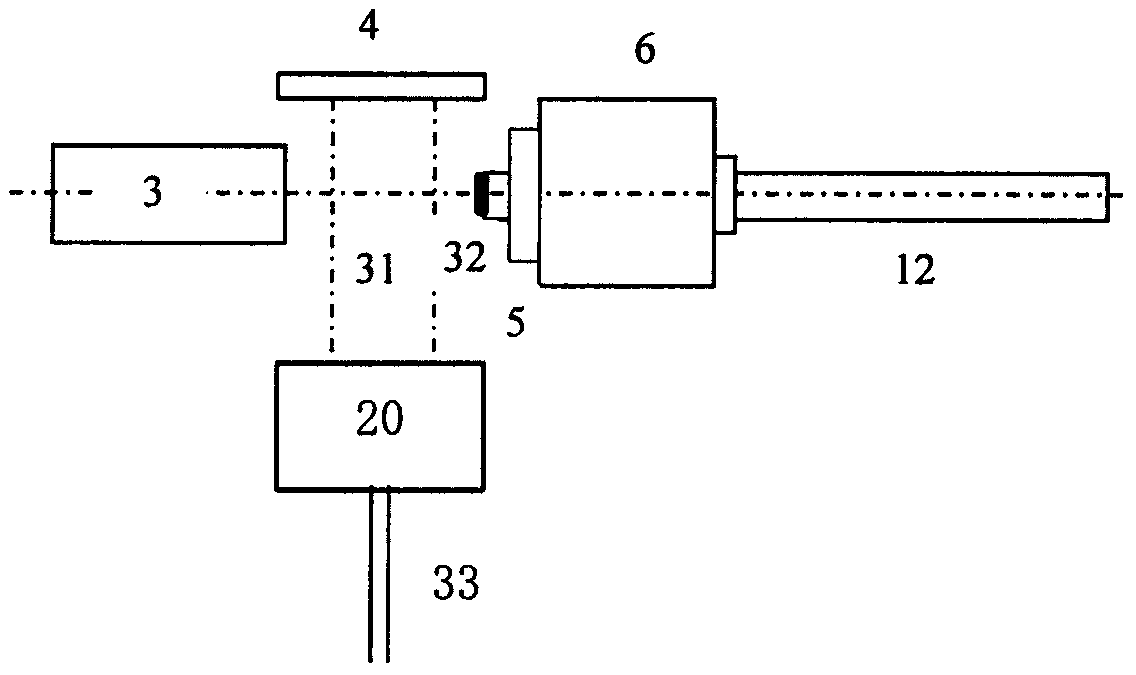

[0027] exist figure 1 In the embodiment, the system mainly consists of three parts: (i) drilling simulation and testing system; (ii) data acquisition system and (iii) data analysis system. The drilling simulation and testing system consists of a pulse generator, a pressurizing mechanism, a pulse shaper, a switching valve, a momentum trap, an experimental rod, a sample and a sample loading chamber, and a rotating mechanism. The pulse generator is composed of a pressure generator, a voltage regulator, a trigger switch and a pulse emission tube. The pressure generator is a pressure source for generating compressed air, driven by 220V alternating current. An impact rod is installed in the pulse emission tube, which forms an impact rod system together with the experiment rod, shaper, conversion valve and momentum converter. The pulse generator triggers the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com