Lysozyme dimer sodium alginate solution preparation degassing and pressure conveying cylinder device capable of adjusting positive pressure and negative pressure automatically

A technology of lysozyme dimer and sodium alginate, applied in gas/liquid distribution and storage, pressure vessel, fixed-capacity gas storage tank, etc., to achieve the effect of easy adjustment, protection of protein invariance, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

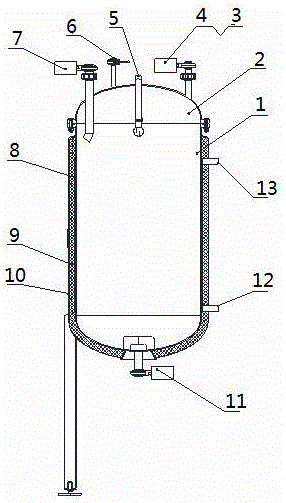

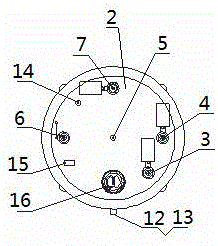

[0019] In this example, see figure 1 and figure 2, a lysozyme dimer sodium alginate solution preparation degassing and pressure delivery cylinder device that automatically adjusts the positive and negative pressures. Composed of a cleaning device and a control system, the cylinder body 1 is sequentially composed of the cylinder inner wall, the medium jacket 8, the insulation layer 9 and the cylinder body shell 10 from the inside to the outside to form an insulation layer system through sequential overlapping and compounding, so that the insulation layer 9 is positioned on the cylinder body shell 10 and the medium jacket 8, and the medium jacket 8 is located between the insulation layer 9 and the inner wall of the cylinder. Install the cylinder head 2 on the upper part of the cylinder body 1 to form a closed pressure vessel chamber inside the cylinder body 1, and install the compressed air input control valve 3, the vacuum control valve 4, and the cleaning spray ball 5 on the...

Embodiment 2

[0031] This embodiment is basically the same as Embodiment 1, especially in that:

[0032] In this embodiment, the internal circulating water pipeline system of the cylinder 1 is used to heat the cleaning agent or water in another closed pipeline, and then the heated cleaning agent or water is delivered to the cleaning spray through another pipeline. The ball 5 sprays and cleans the lysozyme dimer sodium alginate solution preparation degassing and pressure delivery tank that automatically adjusts the positive and negative pressure, and the cleaning liquid or water after spray cleaning is discharged to the special discharge pipe through the control valve (11) at the bottom of the tank , improve the cleaning effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com