Acidic milk powder and preparation method thereof

An acid and milk powder technology, applied in milk preparations, dairy products, applications, etc., can solve the problems of high production cost and low content of fruit juice components, and achieve the effects of good preparation, avoid surface coking, and rich nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

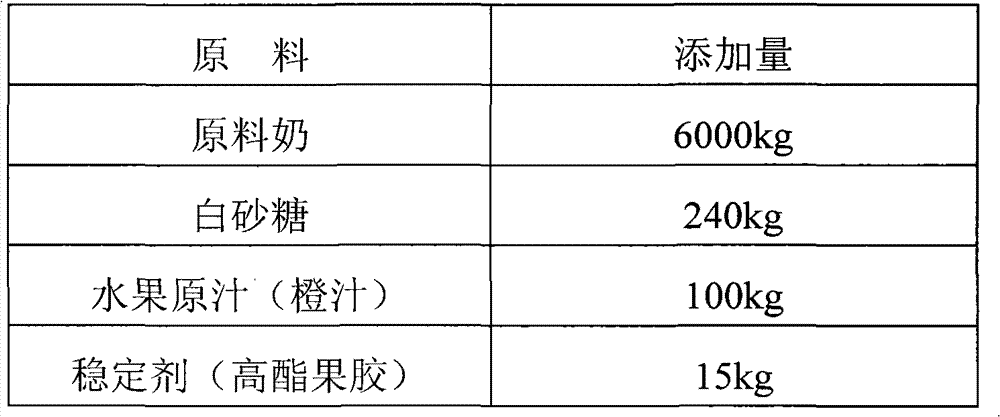

Embodiment 1

[0036] Embodiment 1 orange juice milk powder (contain 10ml orange juice in every 100g milk powder)

[0037] Raw material formula (based on 1000kg milk powder)

[0038]

[0039]

[0040] The preparation process is as follows:

[0041] ①Heat 1500kg of raw milk to 70°C after acceptance and pretreatment, homogenization, pasteurization and other conventional processes, and set aside;

[0042] 2. Preparation of stabilizer solution (concentration 1%): mix 15kg of high-ester pectin with 45kg of white granulated sugar (the weight ratio of the two is 1:3), add it to the spare raw milk in step 1 through a water powder mixer, and stir Dissolve for 15 minutes, then pass through a colloid mill and cool to 25°C for later use;

[0043] ③Preparation of thick milk: after acceptance, pretreatment, homogenization and pasteurization, the remaining raw milk is concentrated by a multi-effect falling film evaporator to obtain thick milk with a solid concentration of 40%, which is ready for us...

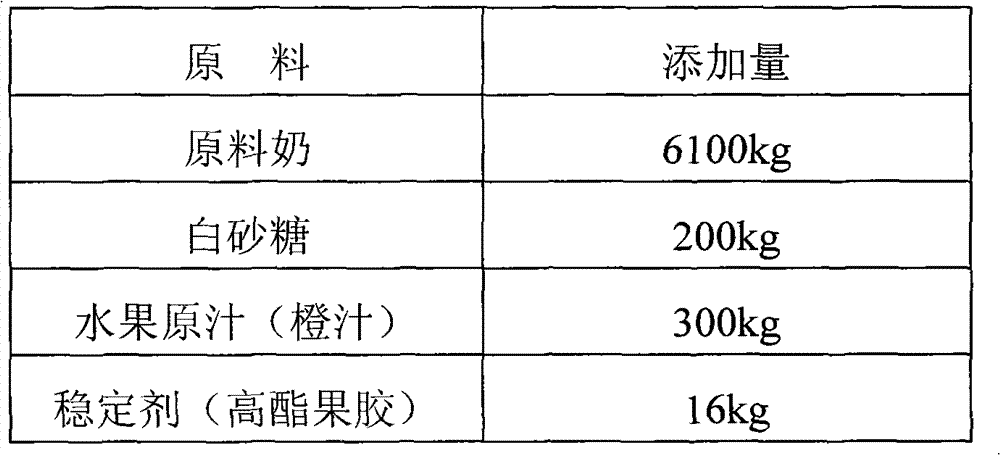

Embodiment 2

[0054] Embodiment 2 orange juice milk powder (contain 30ml orange juice in every 100g milk powder)

[0055] Raw material formula (based on 1000kg milk powder)

[0056]

[0057]

[0058] The preparation process is as follows:

[0059] ①Heat 950kg of raw milk to 71°C after acceptance and pretreatment, homogenization, pasteurization and other conventional processes, and set aside;

[0060] 2. the preparation of stabilizer solution (concentration 1.5%): 16kg high-ester pectin is mixed with 48kg white granulated sugar (ratio both weight ratios are 1: 3), join step 1. in the raw material milk of gained by gouache mixer, Stir to dissolve for 16 minutes, then cool to 24°C after passing through a colloid mill, and set aside;

[0061] ③Preparation of thick milk: After acceptance, pretreatment, homogenization, and pasteurization of the remaining raw milk, it is concentrated by conventional processes to obtain thick milk with a solid content concentration of 41%, which is then use...

Embodiment 3

[0071] Embodiment 3 orange juice milk powder (50ml orange juice is contained in every 100g milk powder)

[0072] Raw material formula (based on 1000kg milk powder)

[0073]

[0074]

[0075] The preparation process is as follows:

[0076] ①Heat 900kg of raw milk to 72°C after acceptance and pretreatment, homogenization, pasteurization and other conventional processes, and set aside;

[0077] 2. Preparation of stabilizer solution (concentration 2%): mix 18kg sodium carboxymethyl cellulose with 90kg white granulated sugar (ratio of both is 1:5 by weight), and add to the raw milk obtained in step 1. by water powder mixer , stirred and dissolved for 20 minutes, then cooled to 23°C after passing through a colloid mill, and set aside;

[0078] ③Preparation of thick milk: after acceptance, pretreatment, homogenization and pasteurization, the remaining raw milk is concentrated by conventional techniques to obtain thick milk with a solid content concentration of 42% for later u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com