Environment-friendly brown digital printing ink and preparation method thereof

A digital printing and environment-friendly technology, which is applied in the field of environment-friendly brown digital printing ink and its preparation, can solve the problems of not being environmentally friendly, increasing the digital printing process, and low color fastness, so as to save production costs and reduce environmental pollution. and health problems, the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

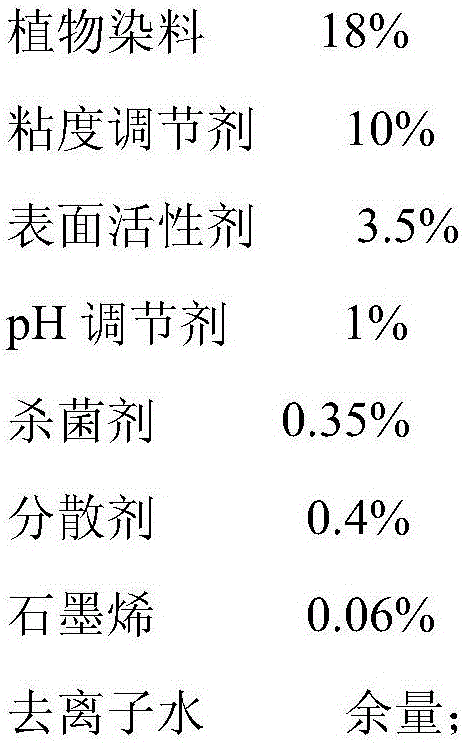

[0027] A kind of environment-friendly type brown digital printing ink, comprises the composition of following percentage by weight:

[0028]

[0029] Described viscosity regulator is glycerol;

[0030] Described tensio-active agent is sodium dodecylbenzenesulfonate;

[0031] Described bactericide is nano titanium dioxide;

[0032] Described pH adjusting agent is sodium carbonate;

[0033] Described dispersant is vegetable oil;

[0034] A preparation method of environment-friendly brown digital printing ink, comprising the following steps:

[0035] A. The Gorgon shell raw material is pulverized to 80 mesh by a micro-plant pulverizer, soaked in deionized water for 2 hours, and the weight ratio of the Gorgon shell to deionized water is 1:30; then ultrasonic extraction is used to obtain a brownish yellow solution, and the ultrasonically extracted The frequency is 50kHz, the extraction temperature is 70°C, and the extraction time is 25 minutes; after filtration, the filtrate...

Embodiment 2

[0039] A kind of environment-friendly type brown digital printing ink, comprises the composition of following percentage by weight:

[0040]

[0041] Described viscosity regulator is glycerol;

[0042] Described tensio-active agent is sodium dodecylbenzenesulfonate;

[0043] Described bactericide is nano titanium dioxide;

[0044] Described pH adjusting agent is sodium carbonate;

[0045] Described dispersant is vegetable oil;

[0046] A preparation method of environment-friendly brown digital printing ink, comprising the following steps:

[0047] A. The Gorgon shell raw material is pulverized to 80 mesh by a micro-plant pulverizer, soaked in deionized water for 3 hours, and the weight ratio of the Gorgon shell to deionized water is 1:20; then ultrasonic extraction is used to obtain a brownish yellow solution, and the ultrasonically extracted The frequency is 40kHz, the extraction temperature is 65°C, and the extraction time is 35 minutes; after filtration, the filtrate...

Embodiment 3

[0051] A kind of environment-friendly type brown digital printing ink, comprises the composition of following percentage by weight:

[0052]

[0053] Described viscosity regulator is glycerol;

[0054] Described tensio-active agent is sodium dodecylbenzenesulfonate;

[0055] Described bactericide is nano titanium dioxide;

[0056] Described pH adjusting agent is sodium carbonate;

[0057] Described dispersant is vegetable oil;

[0058] A preparation method of environment-friendly brown digital printing ink, comprising the following steps:

[0059] A. The Gorgon shell raw material is pulverized to 80 mesh by a micro-plant pulverizer, soaked in deionized water for 1 hour, the weight ratio of the Gorgon shell to deionized water is 1:40; then ultrasonic extraction is used to obtain a brownish-yellow solution, and the ultrasonically extracted The frequency is 55kHz, the extraction temperature is 75°C, and the extraction time is 15 minutes; after filtration, the filtrate is v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com