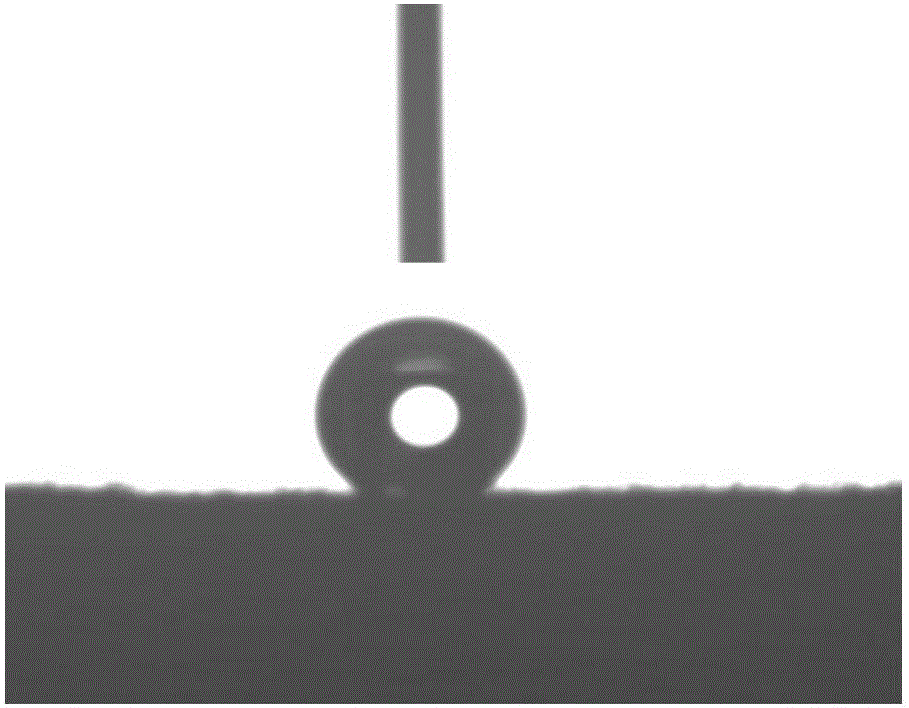

Water-based hollow fluorine-silicon composite water-repellent and breathable textile finishing agent and preparation method

A breathable fabric and finishing agent technology, applied in fiber treatment, textiles and papermaking, liquid-repellent fibers, etc., can solve problems such as cost reduction, achieve the effects of reducing usage, saving fluorine resources, and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0102] A preparation method of an aqueous hollow fluorosilicone composite water-repellent and breathable fabric finishing agent, which comprises the following steps:

[0103] a. Preparation of the emulsification system: Weigh the components of the emulsification system according to the weight of each component, and combine the sorbitan fatty acid ester (Span80), alkylphenol polyoxyethylene ether (OP-10), twelve Sodium alkyl sulphate (SDS), fatty alcohol polyoxyethylene ether (AES) and distilled water are mixed in a magnetic stirring reactor at a temperature of 5~95℃ for 10~40min to prepare an emulsification system for standby, stirring speed=800~2500rpm ;

[0104] b. Preparation of the initiation system: Weigh the components of the initiation system in parts by weight of each component, mix the initiator and distilled water to prepare the initiation system for use;

[0105] c. Preparation of the buffer system: Weigh the components of the buffer system in parts by weight of each comp...

Embodiment 1

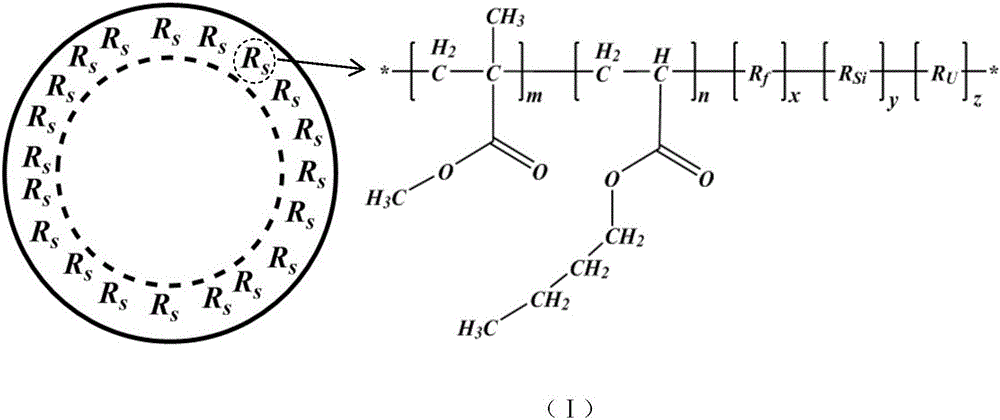

[0112] A water-based hollow fluorine-silicon composite water-repellent and breathable fabric finishing agent, the effective component of which is a hollow fluorine-containing polyacrylate-siloxane composite polymer shell, the structure of the polymer shell is as shown in formula (I) Show:

[0113] In the formula (I), * represents a polymerization reaction site; R S Indicates the structural unit of the polymer shell, m=1, n=100, x=50, y=50, z=50;

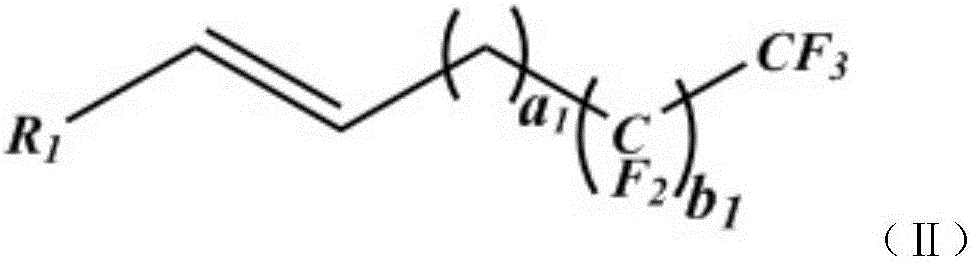

[0114] R f Represents a fluorine-containing monomer, and its structural formula is shown in formula (II):

[0115] In the formula (Ⅱ), R 1 Is H; a 1 =0; b=4;

[0116] R Si Represents organosilicon monomer, and its structural formula is shown in formula (Ⅲ):

[0117] In the formula (Ⅲ), R 1 Et; R 2 Is halogen; a 2 =0;

[0118] R U It means other functional monomer, which is α-hydroxyethyl methacrylate; the specific function of the other functional monomer is a chain extender, end capping agent or diameter extender.

[0119] The R f , R Si , R U ...

Embodiment 2

[0145] A water-based hollow fluorine-silicon composite water-repellent and breathable fabric finishing agent, the effective component of which is a hollow fluorine-containing polyacrylate-siloxane composite polymer shell, the structure of the polymer shell is as shown in formula (I) Show:

[0146] In the formula (I), * represents a polymerization reaction site; R S Represents the structural unit of the polymer shell, m=50, n=50, x=1, y=100, z=1;

[0147] R f Represents a fluorine-containing monomer, and its structural formula is shown in formula (II):

[0148] In the formula (Ⅱ), R 1 Is Me; a 1 =3; b=3;

[0149] R Si Represents organosilicon monomer, and its structural formula is shown in formula (Ⅲ):

[0150] In the formula (Ⅲ), R 1 Is Me; R 2 Is Me; a 2 = 5;

[0151] R U It means other functional monomer, which is α-hydroxypropyl methacrylate; the specific function of the other functional monomer is a chain extender, end capping agent or diameter extender.

[0152] The R f , R Si , R U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com