Process and device for preparing gas-phase white carbon black by taking quartziferous fluorite tailings as raw materials

A technology for fumed silica and fluorite tailings, which is applied in the field of preparing fumed silica, can solve the problems such as the inability of efficient utilization of quartz fluorite tailings, achieve large-scale industrial production, save environmental protection and treat wastewater, and achieve low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments.

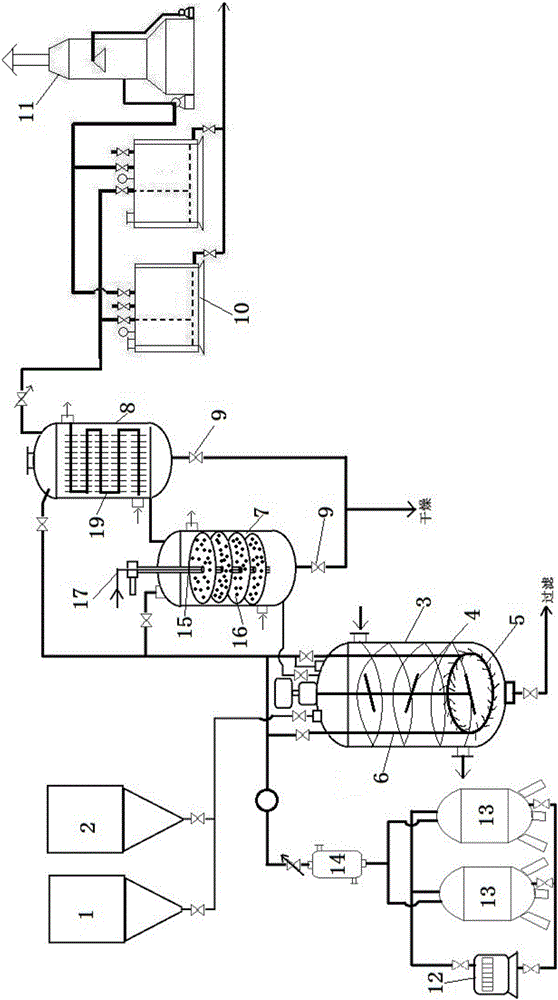

[0030] The structure of the preparation device provided in this example is as follows: figure 1 As shown, the device includes a hot air feeding system, a chemical reaction system, a cooling system and an exhaust gas absorption system, wherein the hot air feeding system is used to store compressed air and send it into the chemical reaction system after heating the air. The hot air feeding system comprises an air compressor 12, an air storage tank 13, an air heater 14 and pipelines, the air compressor 12, the air storage tank 13 and the air heater 14 are connected by pipelines, and the pipelines are also provided with valves and meter.

[0031] The chemical reaction system is composed of an acid liquid storage tank 1, a feed bin 2 and a reactor 3, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com