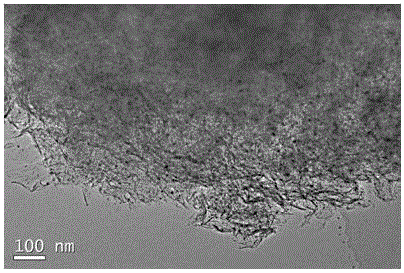

Method for modifying three-dimensional graphene material with carbon nano-dots

A technology of nano carbon dots and graphene, applied in the fields of chemical power supply and nano materials, can solve the problems affecting the application of graphene, and achieve the effect of large specific surface, maintaining structure, and facilitating de-intercalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a three-dimensional graphene material modified by nano-carbon dots, comprising the following steps:

[0034] (1) Preparation of graphene oxide: Graphene oxide was prepared by the improved Hummers method; appropriate amount of natural graphite and sodium nitrate were mixed, at low temperature, a certain amount of sulfuric acid and potassium permanganate were added, and reacted for a period of time. Then add deionized water, raise the temperature to 90° C., and continue the reaction for a period of time. Cool to room temperature, wash with dilute hydrochloric acid and deionized water, and dry to obtain graphene oxide.

[0035] (2) Preparation of the supramolecular sol system of graphene oxide and β-cyclodextrin containing sodium carbonate: take 10 g of graphene oxide, add it to 1 L of water, and ultrasonicate for 6 h to form a sol; then add 1 g of β-cyclodextrin Dissolve in graphene oxide sol with fine stirring, then add 2mL 1mol L -1 The sodium c...

Embodiment 2

[0039] A method for preparing a three-dimensional graphene material modified by nano-carbon dots, comprising the following steps:

[0040] (1) Preparation of graphene oxide: same as step (1) in Example 1.

[0041] (2) Preparation of sodium carbonate-containing graphene oxide and crown ether supramolecular sol system: Take 10 g of graphene oxide, add it to 1 L of water, and sonicate for 6 h to form a sol. Then add 1 g of crown ether and stir to dissolve in the graphene oxide sol, then add 2 mL of 1mol L -1 The sodium carbonate solution was stirred evenly and ultrasonicated for 30 minutes to obtain a graphene oxide and crown ether supramolecular sol system containing sodium carbonate.

[0042] (3) Preparation of three-dimensional graphene materials modified by nano-carbon dots: the supramolecular sol system containing sodium carbonate was frozen in the refrigerator for 24 h, and then dried in a freeze dryer for 48 h. Put the dried sample into the calcination furnace, first at ...

Embodiment 3

[0045] A method for preparing a three-dimensional graphene material modified by nano-carbon dots, comprising the following steps:

[0046] (1) Preparation of graphene oxide: same as step (1) in Example 1.

[0047] (2) Preparation of the supramolecular sol system of graphene oxide and β-cyclodextrin containing sodium bicarbonate: Take 10 g of graphene oxide, add it to 1 L of water, and sonicate for 3 h to form a sol. Then add 5 g of β-cyclodextrin and stir to dissolve in the graphene oxide sol, then add 2 mL of 1mol L -1 The sodium bicarbonate solution was stirred evenly and ultrasonicated for 30 minutes to obtain a graphene oxide and β-cyclodextrin supramolecular sol system containing sodium bicarbonate.

[0048] (3) Preparation of three-dimensional graphene materials modified by nano-carbon dots: the supramolecular sol system containing sodium bicarbonate was frozen in the refrigerator for 24 h, and then dried in a freeze dryer for 72 h. Put the dried sample into the calcin...

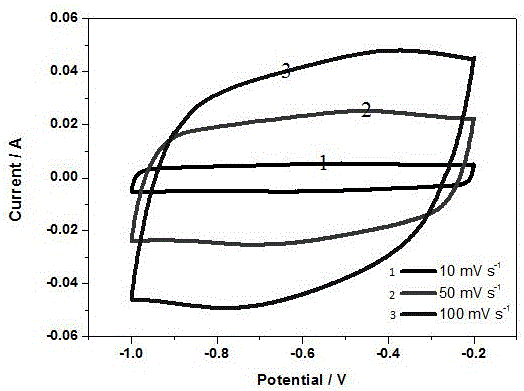

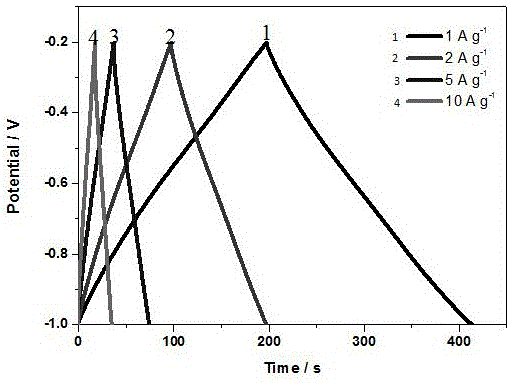

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com