Implementation method based on selective sintering suppression technology for 3D model supporting structure algorithm

A realization method and technology of supporting structure, applied in the field of 3D printing, can solve the problems of high powder consumption and high printing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

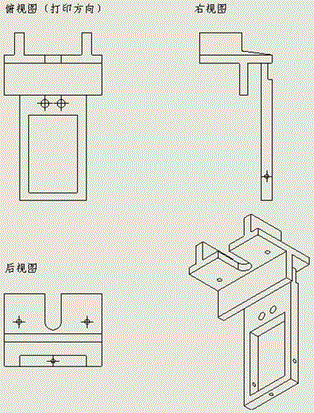

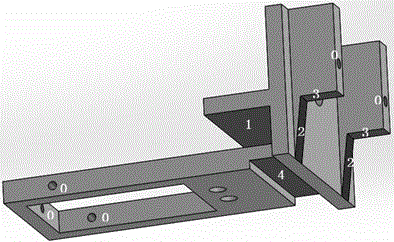

[0041] Please see figure 1 with figure 2 , shown in the figure is the required 3D printed part with a suspended structure, and the selected process parameters correspond to ;

[0042] Please see image 3 with Figure 4 , when the algorithm performs support calculation from top to bottom, when it encounters the following triangular piece of the surface marked in red, , these layers generate supports; in the green area, there are , so it is judged that no support is needed.

[0043] For the support marked as the 0 area, the support starts from the upper surface, and as for the lower surface, it is inside the part; for the support of the 3 surface, the support starts from the upper surface and ends at the formed bottom plate;

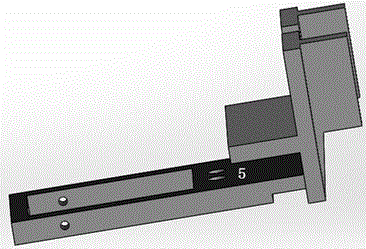

[0044] For surface 1, part of the support starts from surface 1 and ends at surface 5, and part of the support ends at the bottom plate; for surface 4, the forming starts at surface 4 and ends at the bottom plate, because the support is calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com