Rotary positioning machining rotary table

A turntable and processed technology, used in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as relying on horizontal processing, and achieve the effect of compact structure, easy handling and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

[0031] Figure 1 to Figure 5 It is an embodiment of the present invention.

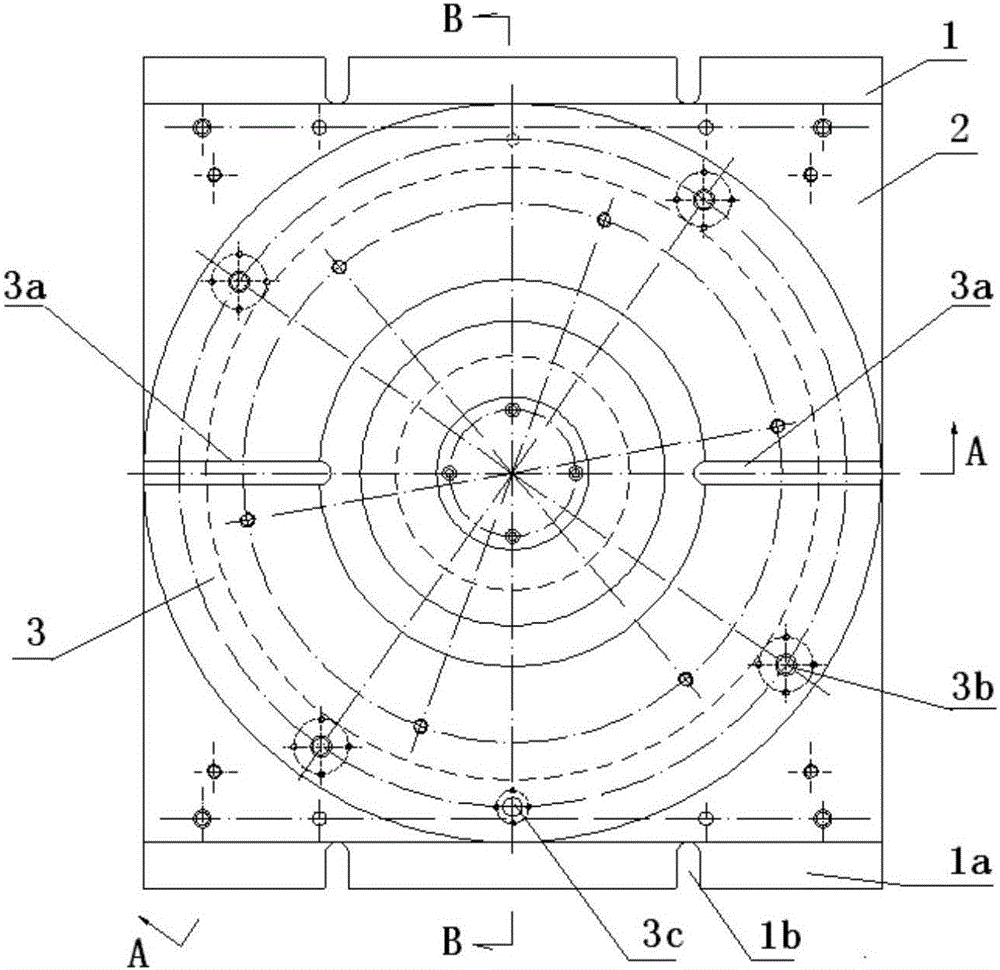

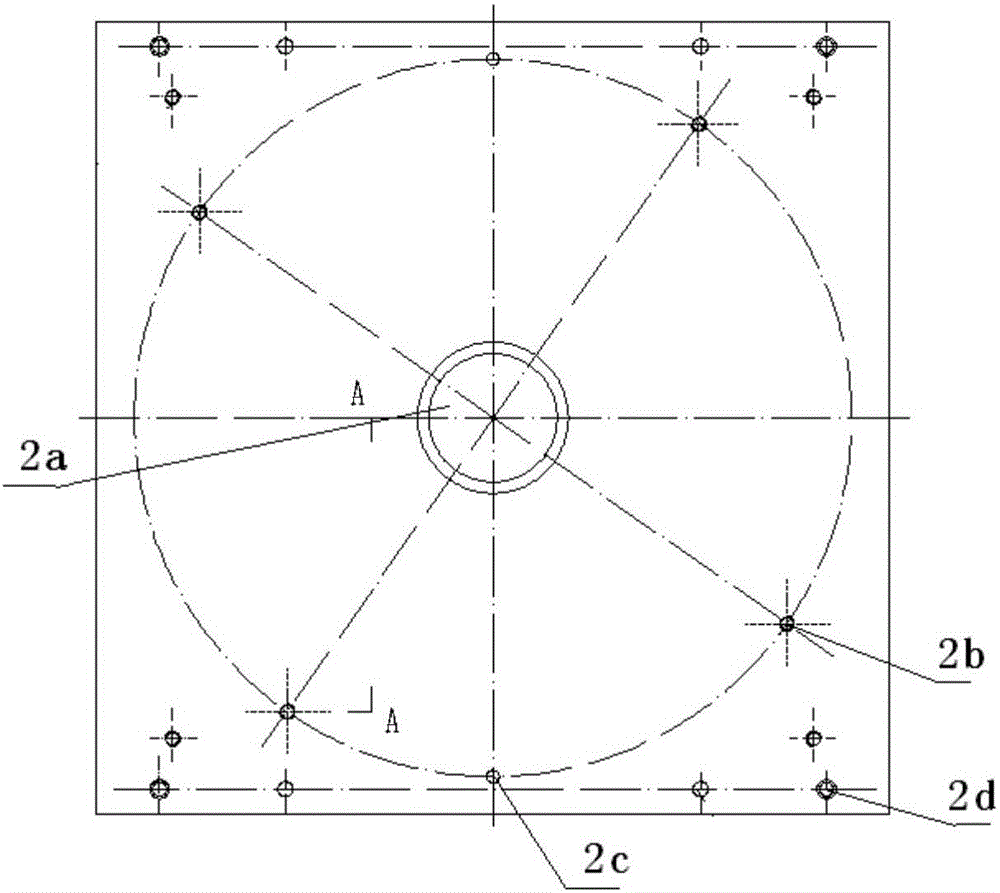

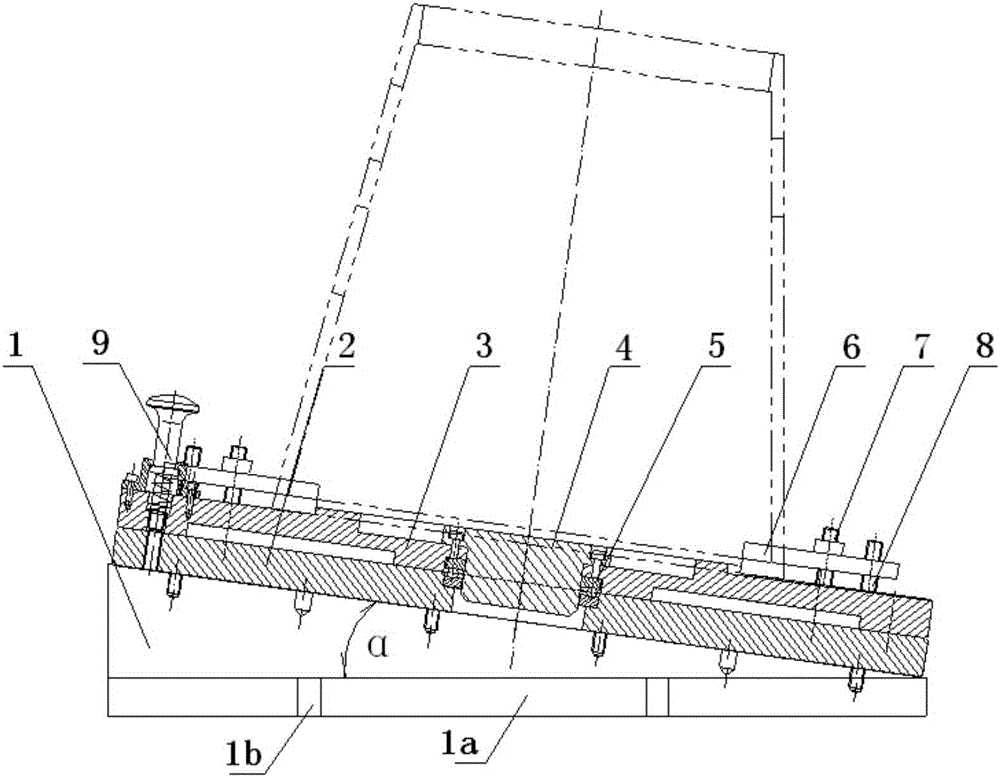

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown: the rotary positioning processing turntable of the present invention includes an angle base, a turntable, a rotating shaft, and a thrust bearing. The slope angle of the angle base 1 is equal to the included angle between the busbar of the processed conical cabin section and the axis, and the turntable bottom plate 2 is installed on the angle base 1. , the turntable 3 is connected to the rotating shaft 4 and installed on the turntable bottom plate 2 through the thrust bearing 5; the center of the turntable bottom plate 2 is provided with a bottom plate step hole 2a for installing the thrust bearing, and the periphery of the turntable bottom plate 2 is provided with evenly distributed b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap