Metal sanitary can and outer complementary coating device and method for weld joint blank area of metal sanitary can

A technology of three-piece cans and coating devices, which is applied in the direction of surface coating liquid devices, coatings, and pre-treated surfaces. It can solve problems such as appearance defects, appearance corrosion, and container leakage, so as to improve product quality and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as figure 1 The one shown is a three-piece can, which has a bottom cover 61, a can body 62 and a top cover 63. There is a weld 64 on the can body 62, and there are weld voids 65 on both sides of the weld 64, and the weld void 65 It is coated with a UV photocurable paint layer 66 .

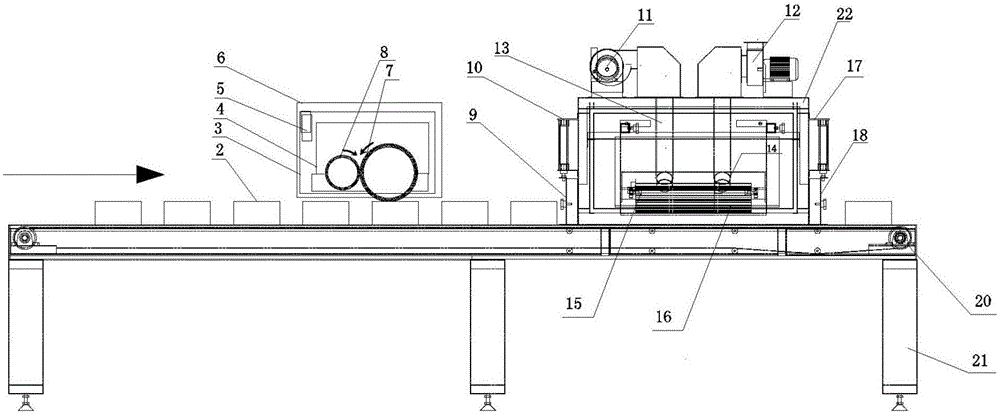

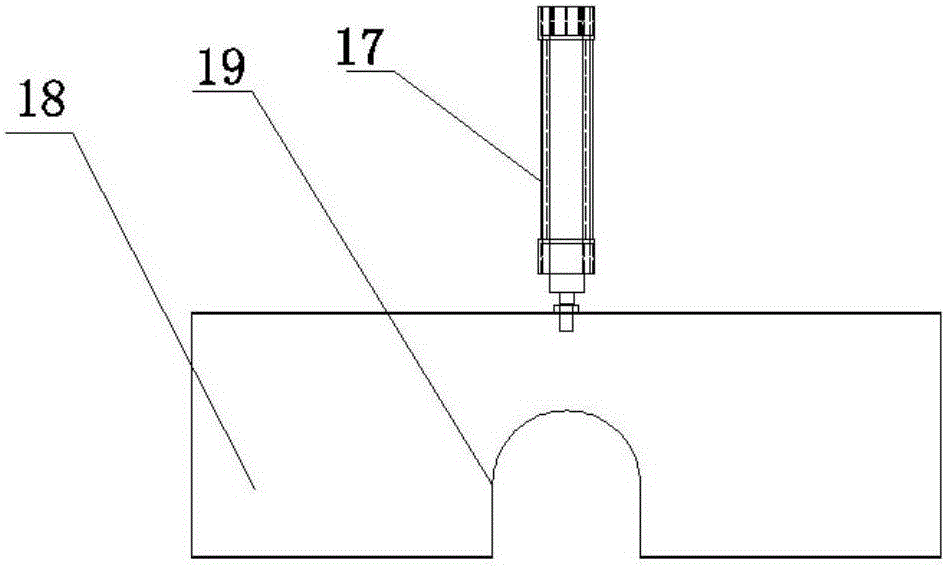

[0031] Such as Figure 2 to Figure 3 The external repair coating device for the weld gap area of a metal three-piece tank shown includes a bracket 21, and a tank body conveyor belt 20 is arranged above the bracket 21, and the tank body conveyor belt 20 is sequentially arranged for feeding the tank body. 2, the outer weld seam coating device 6 and the photocuring device coated with UV photocuring paint in the weld blank area; the photocuring device includes a housing 22, a UV lamp 15 is arranged in the housing 22, and a UV lamp 15 is arranged outside the UV lamp 15. Lamp ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com