Flexible organic semiconductor laser and manufacturing method thereof

An organic semiconductor and laser technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of high production cost, inflexible performance, complex production process, etc., and achieve low cost and excellent flexibility. , the effect of low threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] For the preparation of the flexible substrate, silicone oil and photocuring agent are selected, and the mass ratio is 10:1, and they are stirred evenly; then, the evenly stirred mixed liquid is dropped on the prepared glass sheet, and scraped; put it in a vacuum drying box, Vacuum until there are no bubbles, raise the temperature to 80 degrees Celsius, and take it out after 30 minutes.

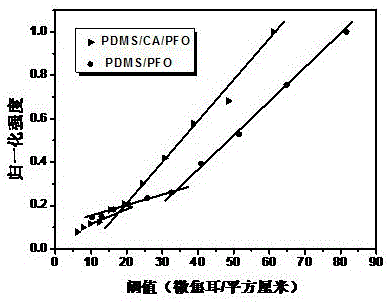

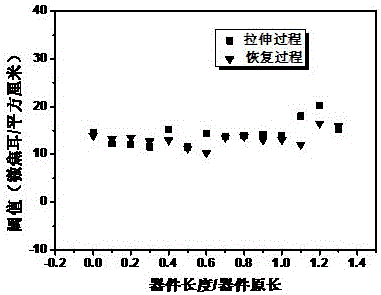

[0016] For the preparation of the laser device, spin-coat the flexible substrate prepared above. First, because the contact angle of the prepared substrate is relatively large, it needs to be pre-treated on the surface before it can be spin-coated better. Plasma treatment is selected for 10s. Then spin-coat the isopropanone solution of cellulose acetate in the water-soluble organic interface layer, CA / DAA, 25mg / mL, at a speed of 3000r / min, and finally spin-coat the luminescent layer of PFO, 20mg / mL, at a speed of 2000r / min. By introducing an interface layer, the film-forming property of...

Embodiment 2

[0019] The flexible substrate was prepared according to the method of Example 1.

[0020] For the preparation of the laser, the prepared flexible substrate is spin-coated, the surface is pretreated, treated with Plasma for 10s, and then spin-coated with a water-soluble organic interface layer of cellulose acetate in isopropanone solution, CA / DAA, 20mg / mL, rotating speed at 3000r / min, and finally spin-coat the light-emitting layer PFO, 30mg / mL, at a speed of 2000r / min. By changing the concentration of the solution, changing the thickness of the interface modification layer and the organic semiconductor laser gain medium, and observing the change of the laser performance, it is found that the threshold value becomes slightly larger.

Embodiment 3

[0022] The flexible substrate was prepared according to the method of Example 1.

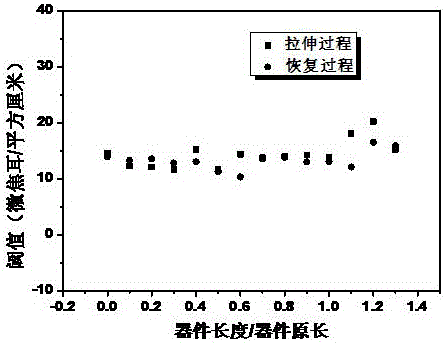

[0023] For the preparation of the laser, the prepared flexible substrate is spin-coated, the surface is pretreated, treated with Plasma for 10s, and then the water-soluble organic interface layer polyelectrolyte (PEs) is spin-coated at 20mg / mL at a speed of 3000r / min, and finally Spin-coat the luminescent layer of PFO, 20mg / mL, and the rotation speed is 2000r / min. By changing the solution and solution concentration of the interface modification layer, observing the effect of changing the solution and thickness of the interface modification layer on the performance of the laser, it is found that the interface modification layer is a water-soluble organic interface layer polyelectrolyte, PEs, water-soluble organic interface layer acetic acid The isopropanone solution of cellulose, CA / DAA, as the interface modification layer, has more stable properties measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com