Silver paste combination for secondary printing of crystalline silicon solar cell

A crystalline silicon solar cell and secondary printing technology, which is applied in the field of solar cells, can solve the problems of small contact area between electrodes and silicon wafers, incomplete corrosion of the sub-gate bottom layer, and large leakage Irev1, so as to improve light conversion efficiency and reduce leakage. Current, the effect of increasing Eff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Combine 80 g of silver powder (average particle diameter of 2.5 μm) and glass powder (lead tellurate system glass powder T g : 253°C, 2g; bismuth tellurate system glass powder T g : 281°C, 1g) 3.0g, organic vehicle (Texanol: ethyl cellulose: lecithin: triethanolamine is 8.5: 1: 0.3: 0.2 (wt / wt)) 9g is pre-mixed in a mixer, and then mixed in a three-roller Mix and roll on the machine to get three front-side silver pastes.

[0033] Silver powder (average particle size: 2.5 μm) 80g, bismuth tellurate system glass powder (T g : 569°C) 3.0g, organic vehicle (Texanol: ethyl cellulose: lecithin: triethanolamine is 8.5: 1: 0.3: 0.2wt / wt) 9g is pre-mixed in a mixer, and then mixed and rolled on a three-roller machine , to obtain four front-side silver pastes.

[0034]Take the silicon wafer that has been textured, diffused, and PECVD, and screen-print the back silver paste and the back aluminum paste, and then screen-print the three front-side silver pastes and four front-side...

Embodiment 2-4

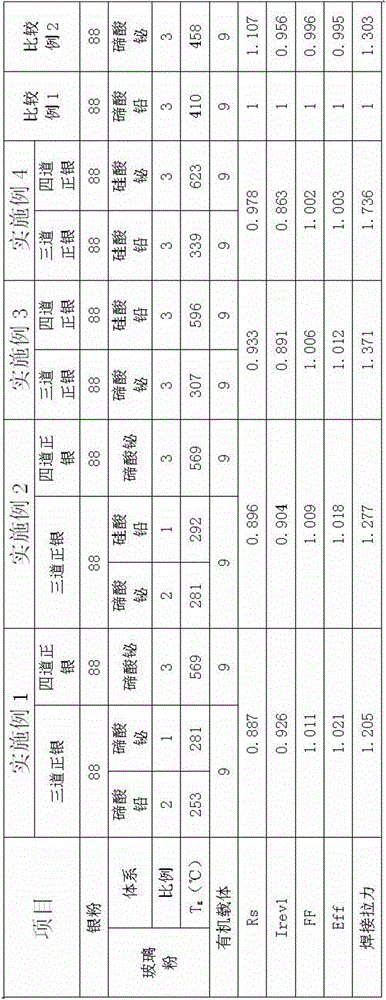

[0037] In embodiment 2-4, the preparation process of three front silver pastes and four front silver pastes and the cell preparation process are similar to those in Example 1, except that the glass used for three front silver pastes and four front silver pastes is changed. Pink T g outside. The composition and battery performance results of the three-layer front-side silver paste and four-layer front-side silver paste of Examples 2-4 are shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com